Building an electric racing motorbike from scratch

Introduction

Motostudent is an international competition where students must design, build, and test a prototype racing motorcycle. In this post, I will summarize around a year of work and walk you through the process of building an electric racing motorcycle from scratch. This project covers a wide range of technical and non-technical areas, which I will break down into key sections. The main sections will focus on mechanical, electrical, and powertrain aspects, each of which includes numerous subsections as outlined in the index.

Approach to the project

As told before, the goal of the project is to design and build an electric motorbike. The main aim should be to apply all this knowledge, that is supposed we should have learned in the university, into practical real world scenario.

We were racing in representation of the University of Burgos (which didn’t help too much to the team). We even didn’t have a space for work inside the university, so we looked for local companies that allow us to work on their facilities and with their tools, machines etc. I left the university a few years ago, but I enrolled on one subject again to participate in this project (Motostudent organization requires team members to be enrolled in the university to participate on the final event). The project is supposed to be extended during two years, but the real execution of the project always is less than that. All the work shown here has been made in 8 months (plus some experience from previous edition).

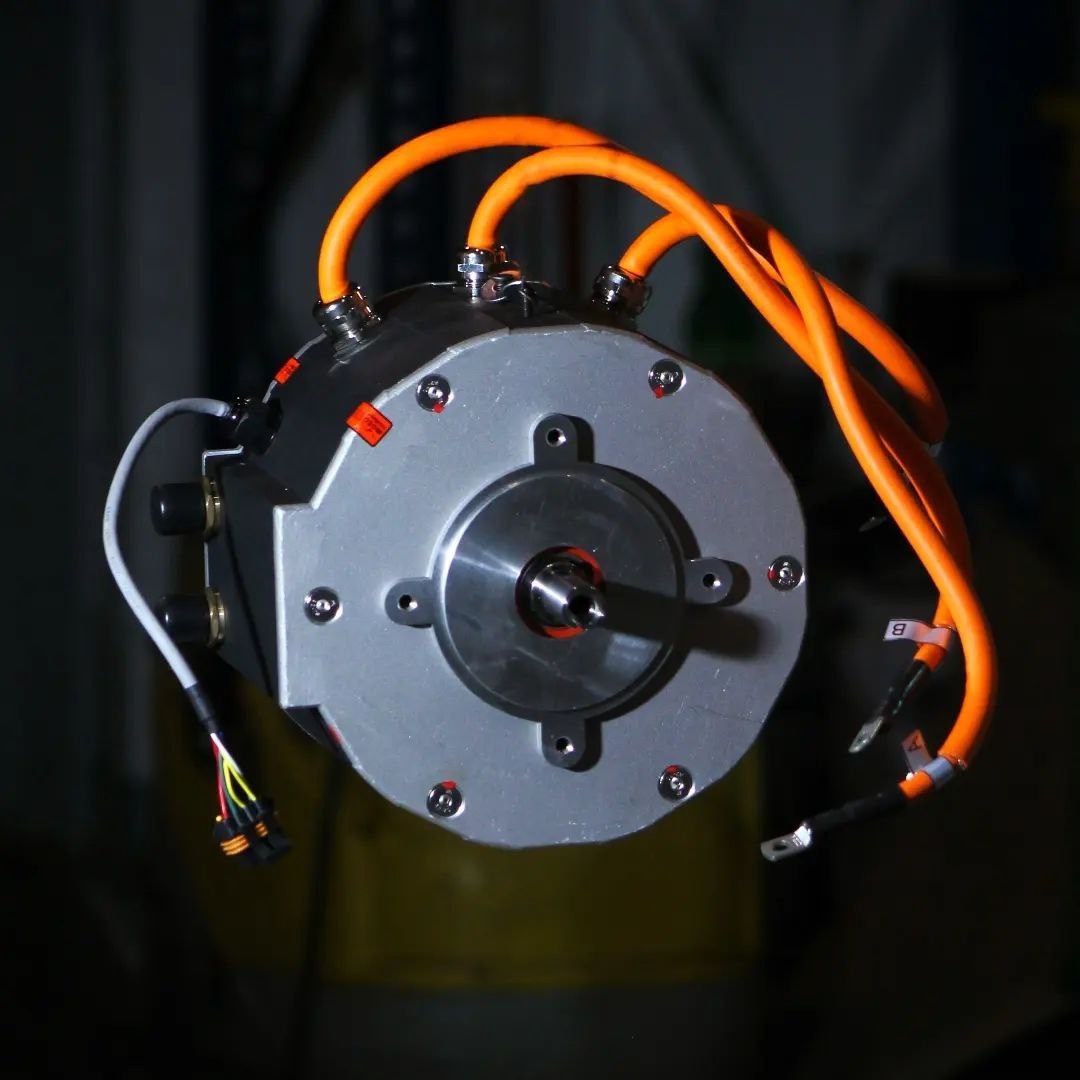

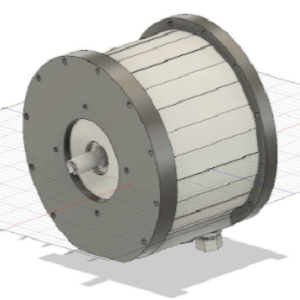

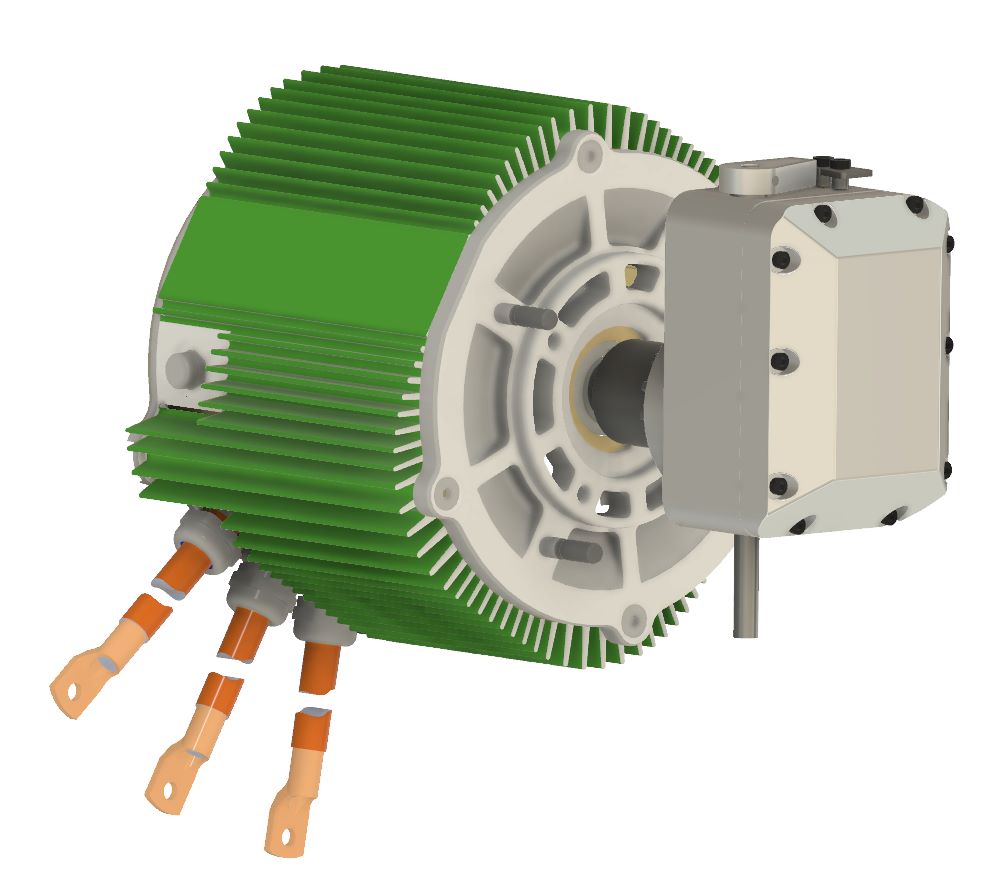

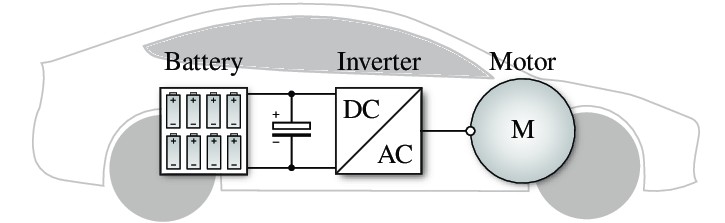

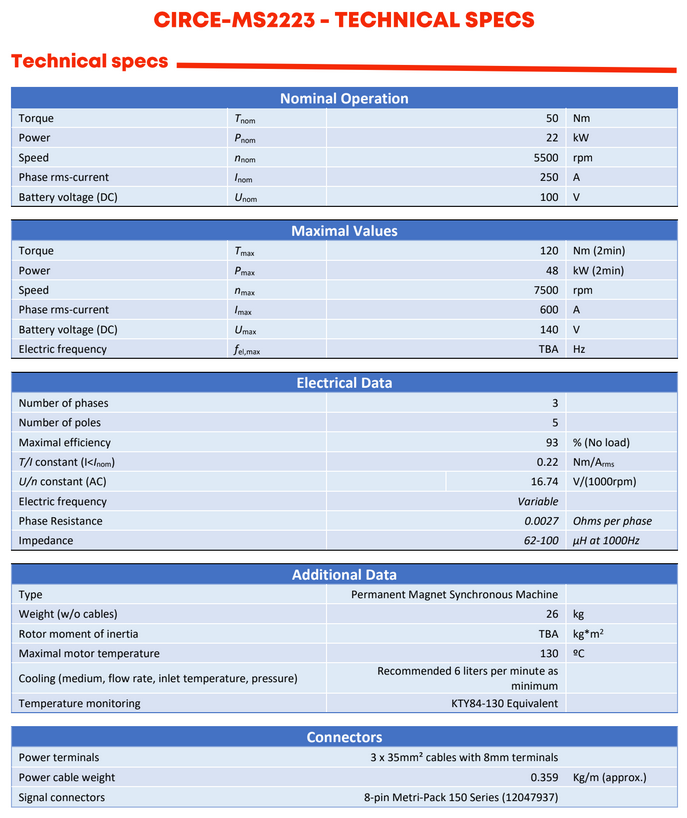

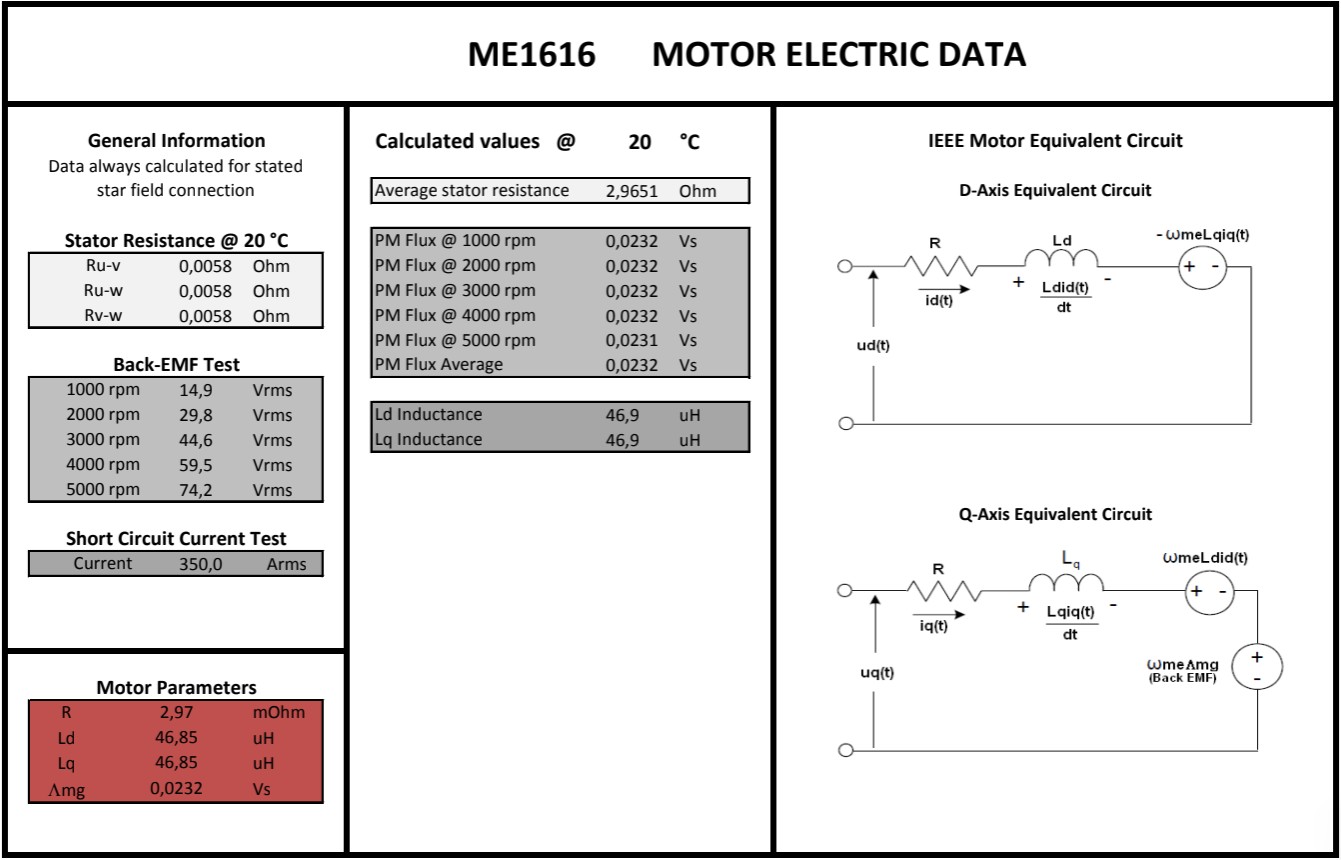

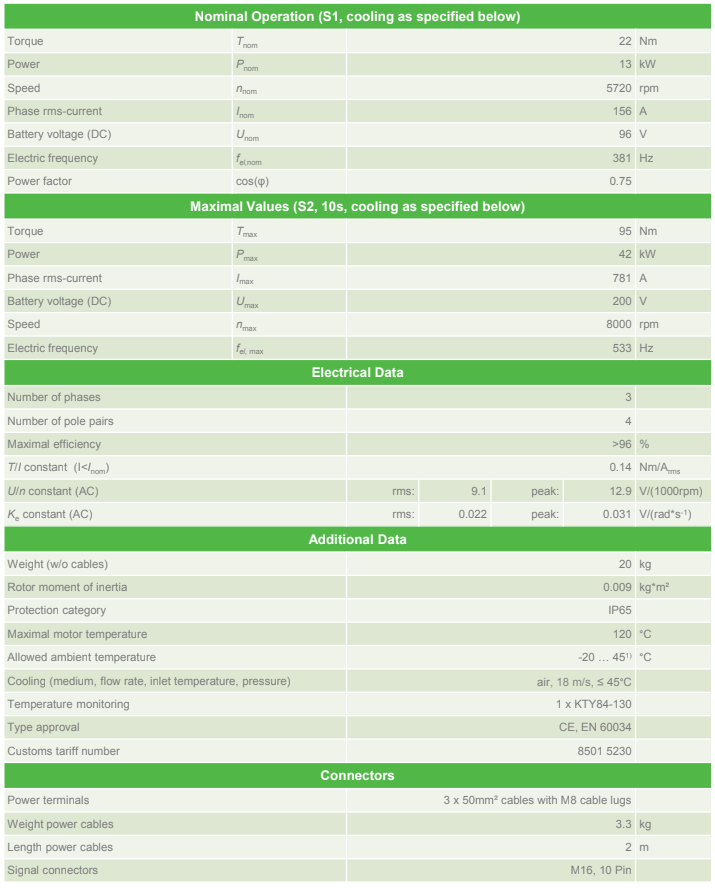

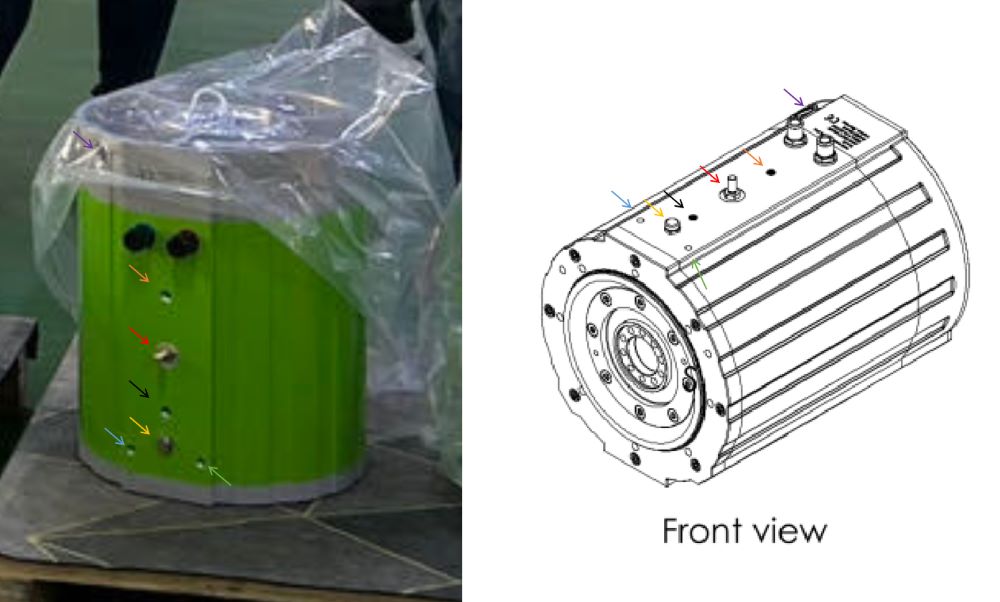

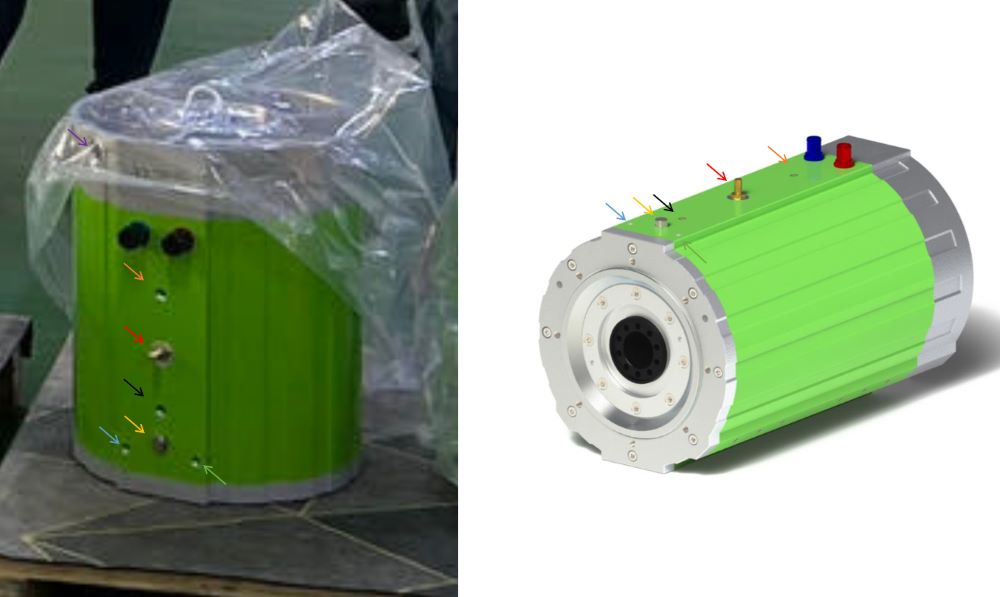

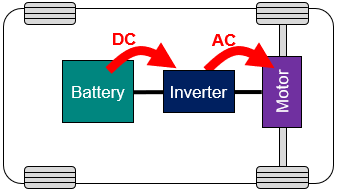

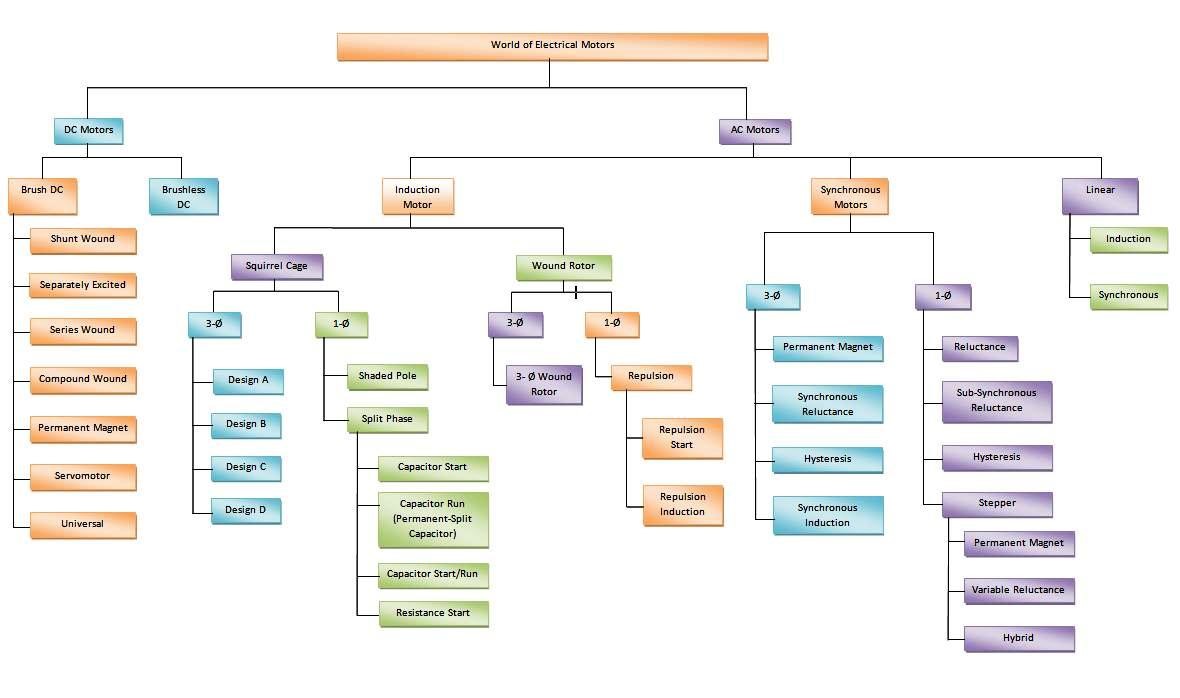

In Motostudent, we can find two categories: petrol and electric. In both categories, organization gives you a pair of tires, front and rear brake calipers and front and rear brake pumps. In petrol category they give you a 250cc 4-stroke KTM engine. In electric one, they give you an 3-phase permanent magnet AC electric motor and IMD (Isolate Monitoring Device, we will talk about it later). We will talk about the motor later too.

Material provided by the organization in the 2022-2023 edition.1

Material provided by the organization in the 2022-2023 edition.1

The team must send some documentation to the organization for evaluation and to check if, for example, minimal security measures are accomplished, such as battery assembly, structural rigidity, etc.

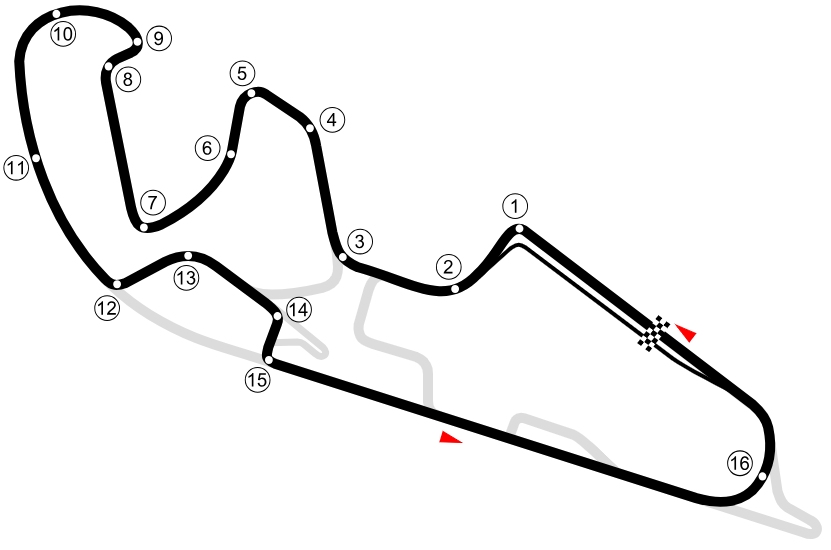

Once the prototype is finished, there is a final test at the Motorland circuit, in Aragon, Spain. All the teams travel one week with the prototypes to race against others.

Motostudent final event1

Motostudent final event1

There are two type of tests on the final event:

Static tests: In these tests, the organization verifies whether the prototype meets safety standards and regulations.

- Weight check: There is a minimum weight on the prototype of 85 kg, but on electric category we are far away from that weight.

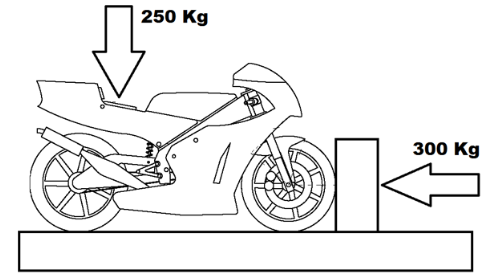

- Load check: Organization loads 250 kg on seat and 300kg between axis and checks the structure behavior of the prototype.

- Break check: Organization tests the brakes of the prototype with a dynamo-meter.

- Isolation resistance measurement check: The isolation between the high voltage and the prototype chassis must be at least 100 ohms/V.

- IMD check: Organization connects a 50k ohmn resistor between the chassis and battery positive. The IMD must open the circuit and cut the power (HV) in 30 seconds. Or prototype cut in 2 seconds.

- Rain check: Organization sprays water during 60 seconds and waits another 60 seconds. The prototype must work after that time, simulating rain conditions.

Rain test of the current prototype1

Rain test of the current prototype1

Dynamic tests: In these tests the teams compete among them to see which is the best in each category.

- Brake test: The prototype must enter at 80km/h and brake as soon as possible. The shortest distance wins.

Breaking test1

Breaking test1

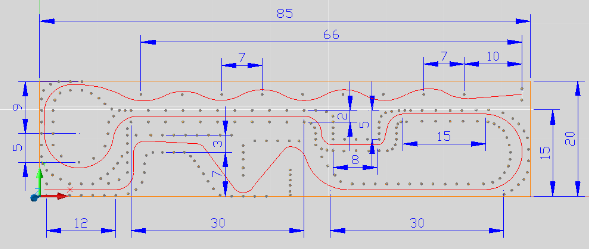

- Gynkhana: There is a small circuit and they test the maneuverability of the bike. A good rider is important here!

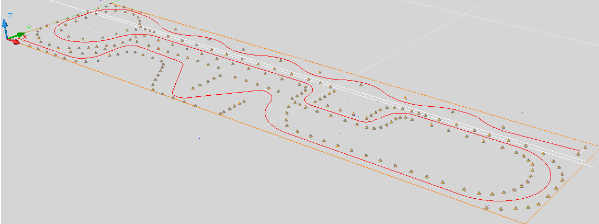

Sketch of the gynkhana1

Sketch of the gynkhana1

3D Sketch of the gynkhana1

3D Sketch of the gynkhana1

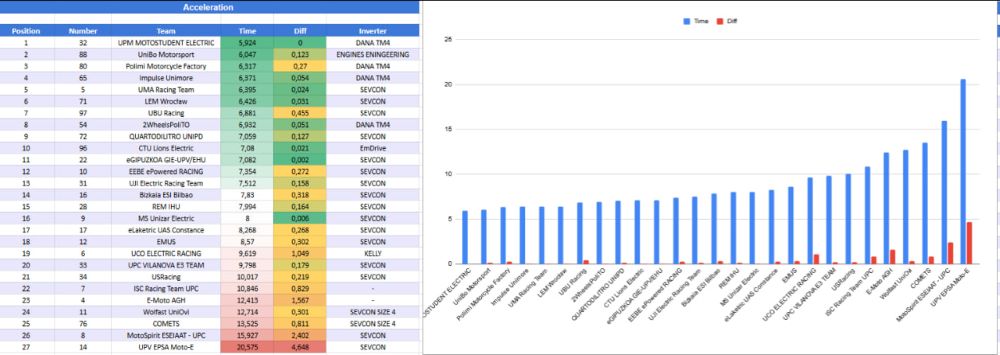

- Acceleration: Organization checks the time spent to accelerate form 0 to 150 meters.

- Max speed: Maximum speed is checked at the end of the rear straight.

- Regularity: One sector of the circuit is measured during multiple laps to check how regularly can the teams do the sector, trying to make the same tame on all laps.

- Pole position: Fastest prototype in one lap.

- Best race lap: Fastest lap of a prototype in the race.

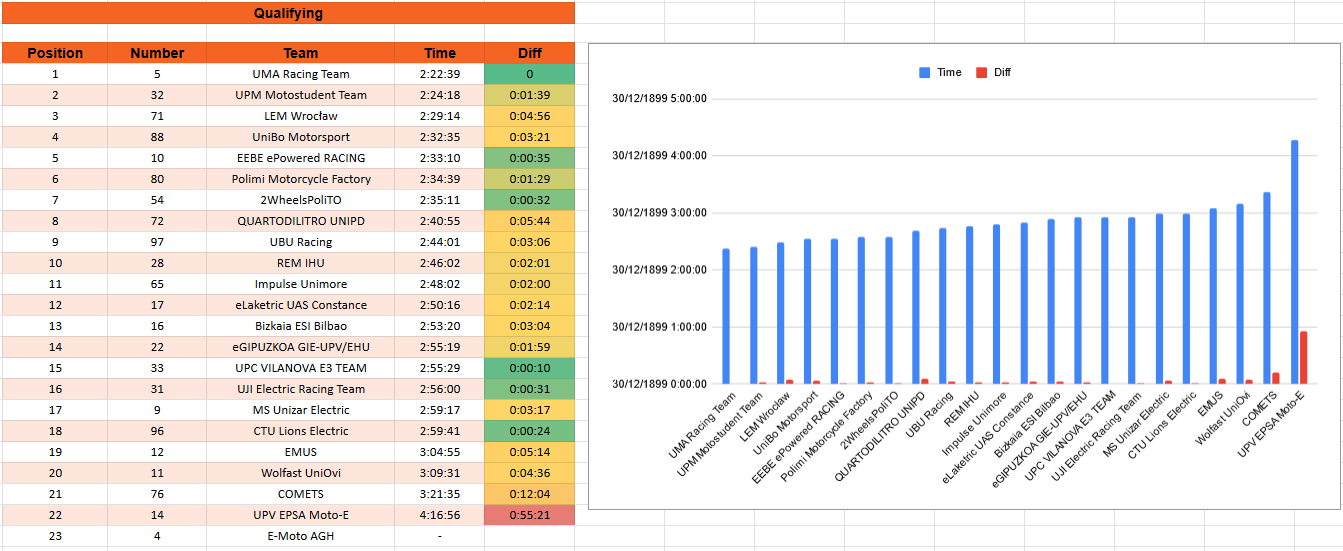

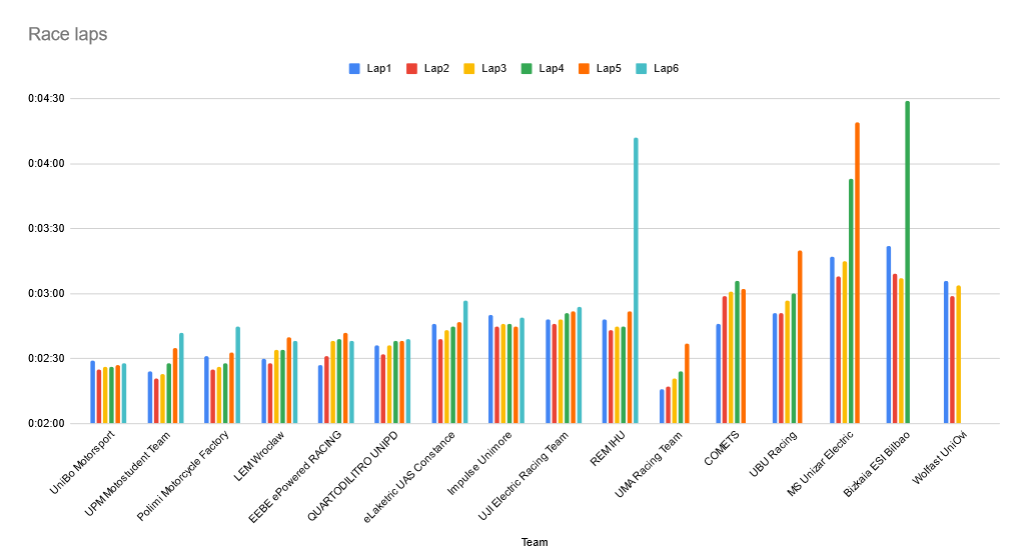

- Race: Final race between all teams. It’s 6 laps to Motorland MotoGP Circuit with 5 km per lap that give us around 30 km of race.

Previous editions

I gave a short introduction about the competition and some of it’s regulations. That’s everything we had when we started the project, nothing more. We even didn’t have an euro to start or a place to work. The team was very small, it’s difficult to find people with compromise nowadays and more on a project like this that requires too much time and effort and doesn’t give any salary or short-term rewards.

Motostudent has an edition every two years. The University of Burgos has been participating during the previous 6 editions. All of this editions with petrol bike except the last one and the third year that they did both, petrol and electric one. From my point of view, there are some big problems with the team:

- The team is renewed every edition: On all previous editions, there weren’t people from the previous edition, so there is no relief.

- Lack of university involvement: It’s supposed that the team represents the university, but there is even no teachers following the project. There is also no place for meeting and store all the things and materials of the project. The university doesn’t even pay for the full registration of the team!

- There is no documentation: There is no more documentation than the reports sent to the organization on previous editions and that doesn’t cover everything or important aspects of the technical challenges solved on previous editions.

- There wasn’t knowledge: The first electric prototype was started (from the electrical point of view) not by the students. They were helped by a external company, so no internal knowledge could be left on the team.

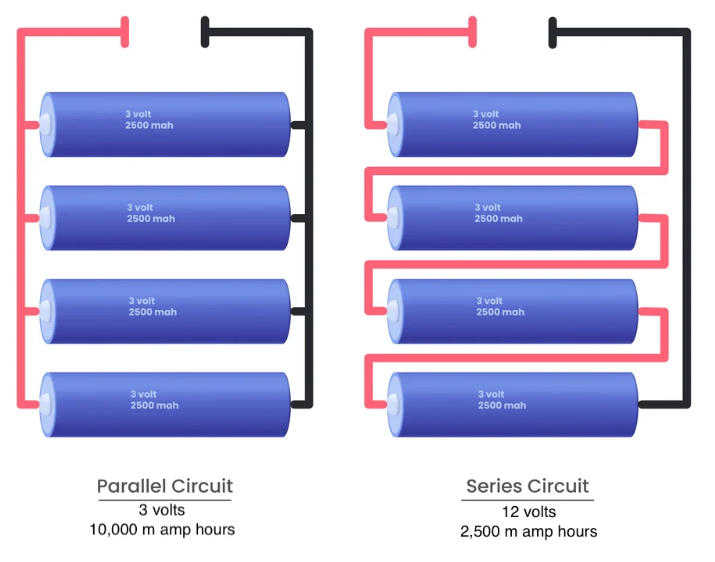

- Decline in education: Getting a degree is nowadays easier than ever. Students exit from the university without the minimal knowledge and base about the degree they are studying at the level that a electronic engineer student on their last year doesn’t know the different between series and parallel connections. Imagine if you have to build a electric motorbike or a battery with that knowledge! You need to re-teach students again only for the project.

I joined the team late on the second electric prototype (2020-2021). Of course, I didn’t have any idea about how to program the inverter, how batteries work, or even some basic electrical concepts (I’m computer engineer). That’s what I will try to explain on all this posts and keep a documented record of the process.

I will focus on the actual prototype as in the previous one there were a lot of decisions taken when I arrived, but let’s look it briefly.

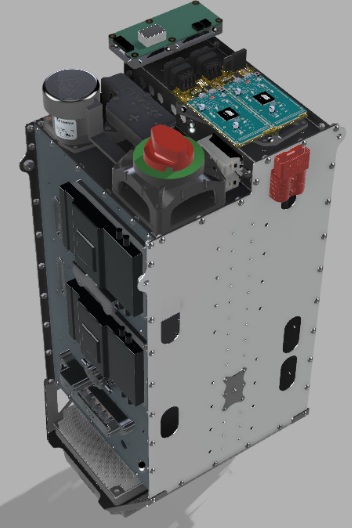

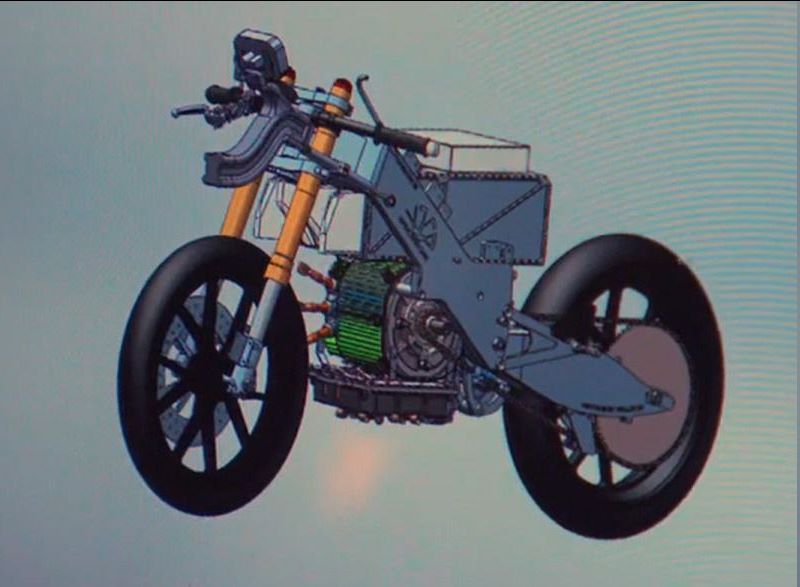

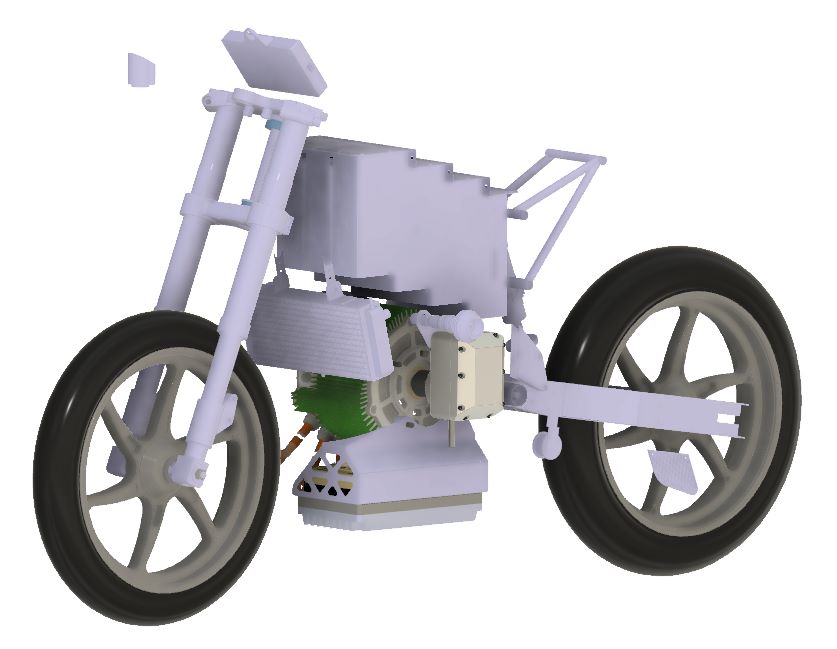

Here is a CAD of the previous prototype:

Unfinished 3D design from previous prototype.

Unfinished 3D design from previous prototype.

The 3D design wasn’t even finished and a lot of things were done on the fly. I don’t like that methodology because CAD software exist for something. When something is not designed and it’s manufactured in a hurry, it is a mess (laser cutting vs rotaflex for example).

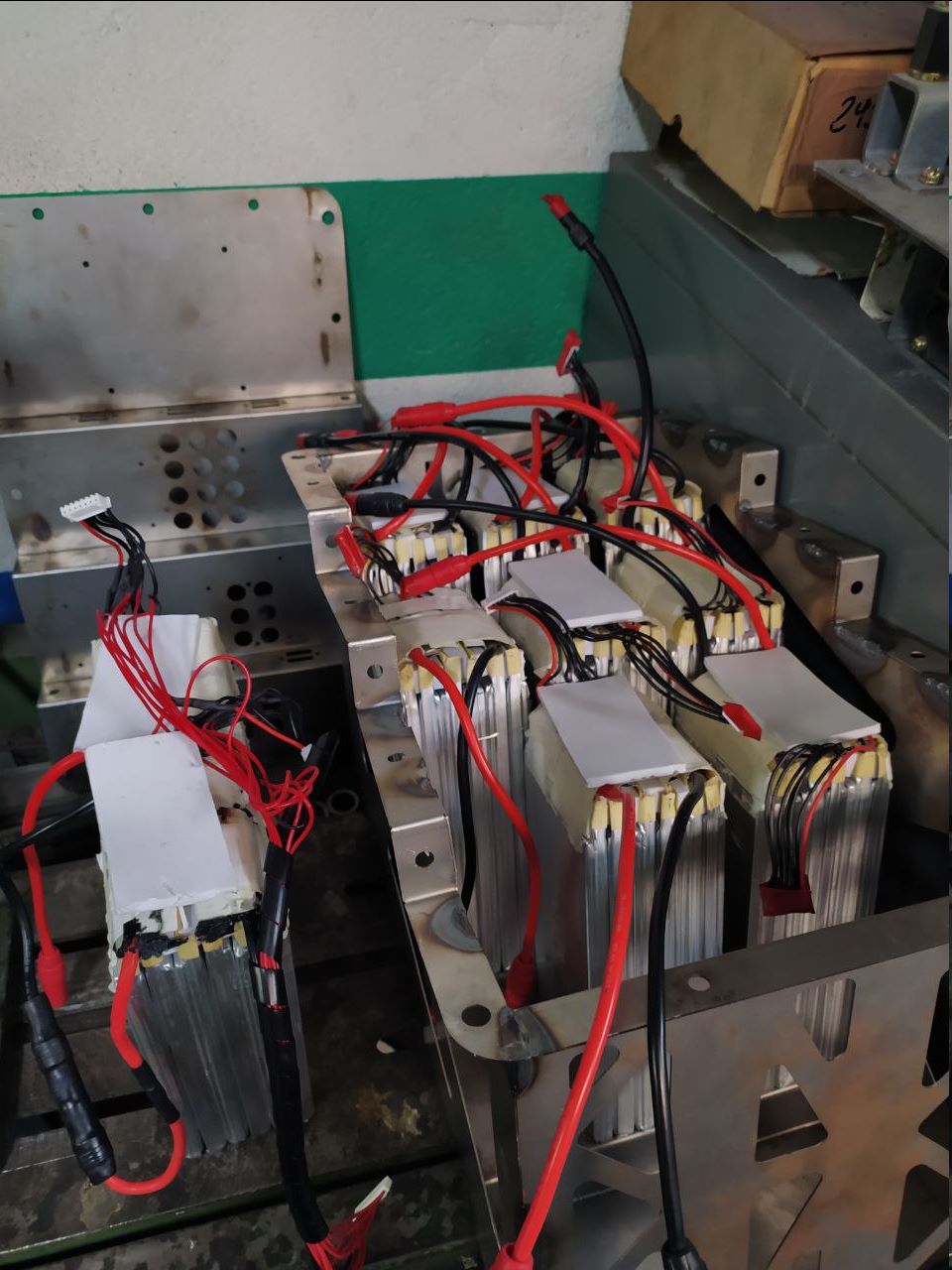

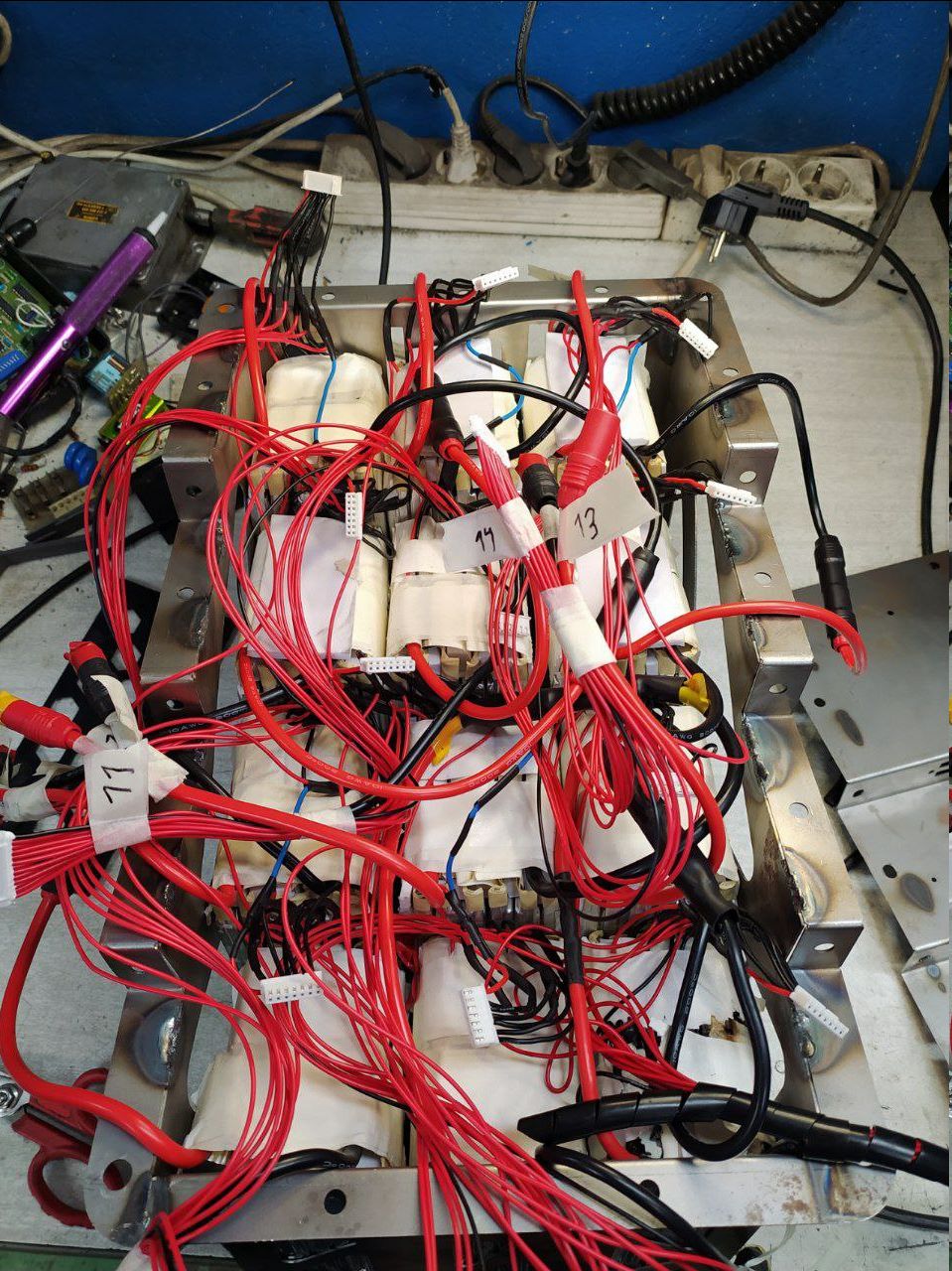

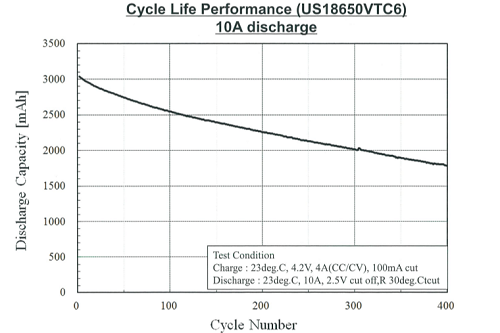

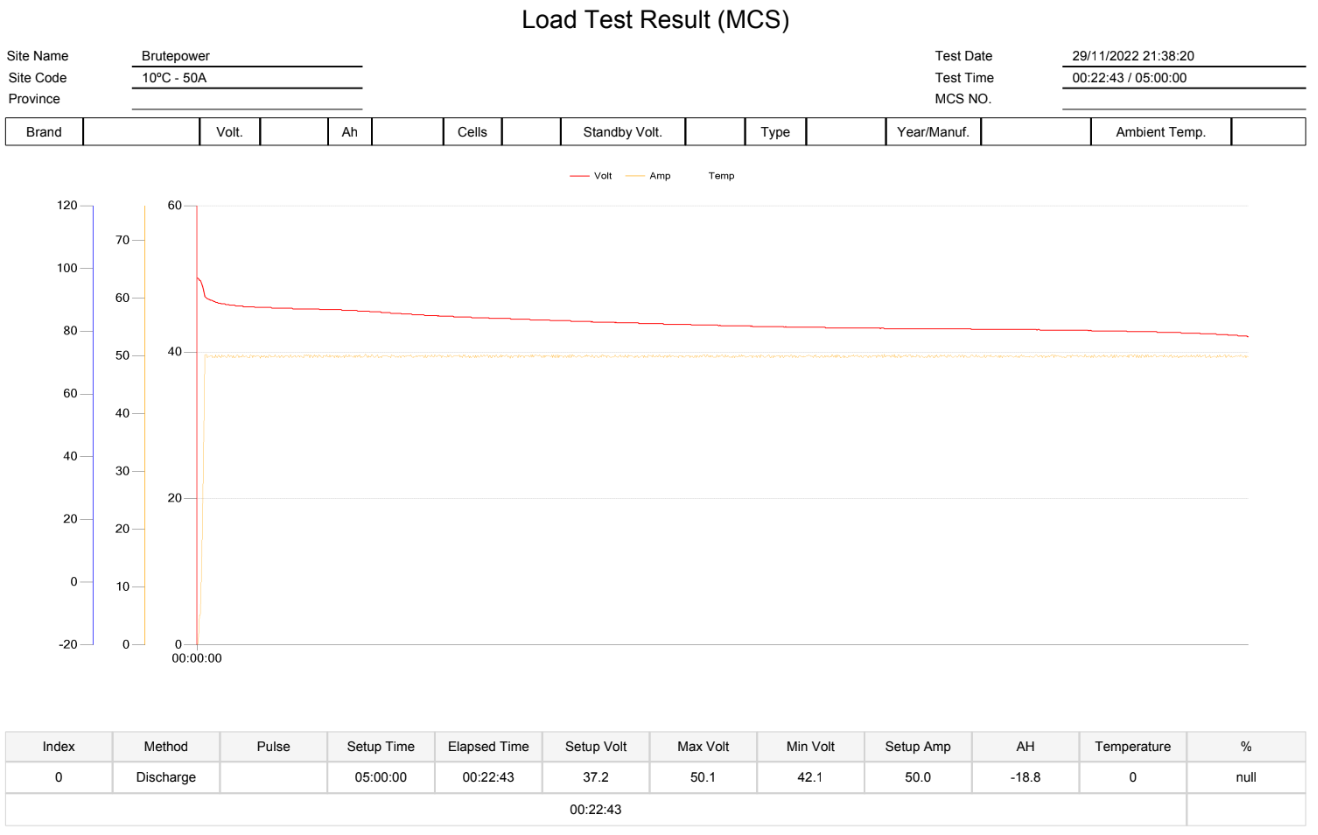

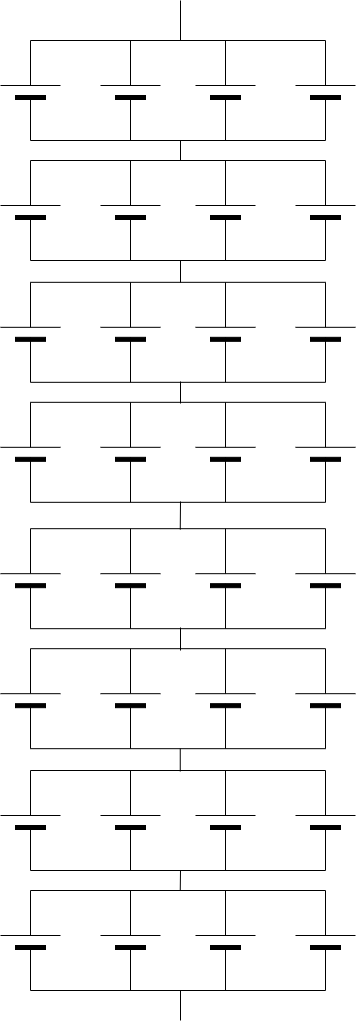

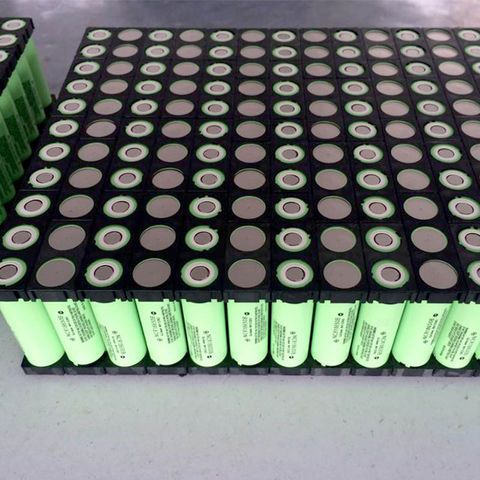

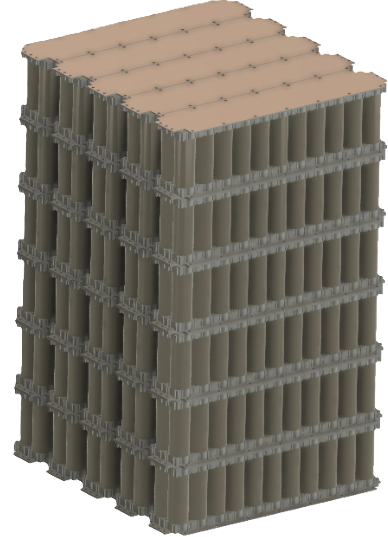

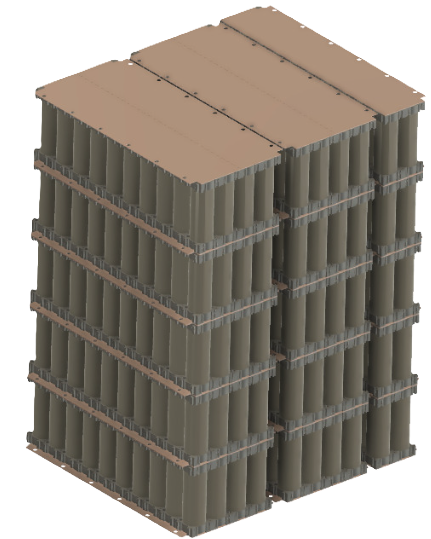

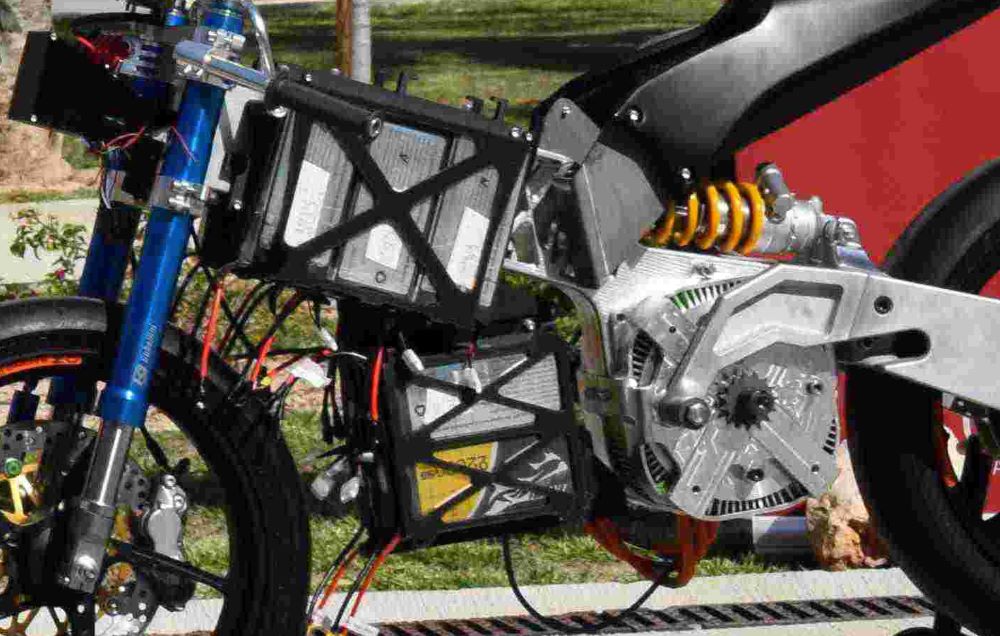

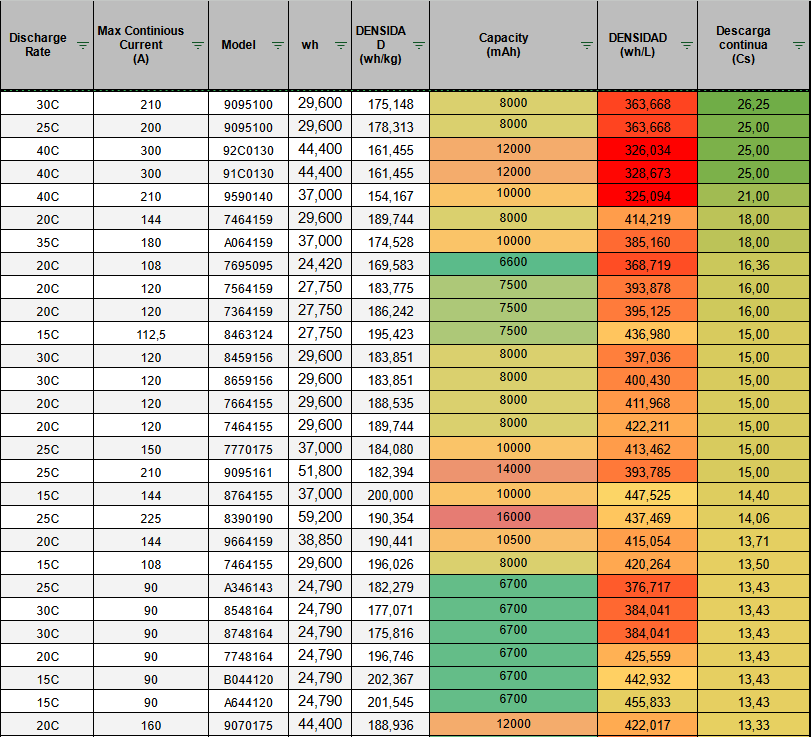

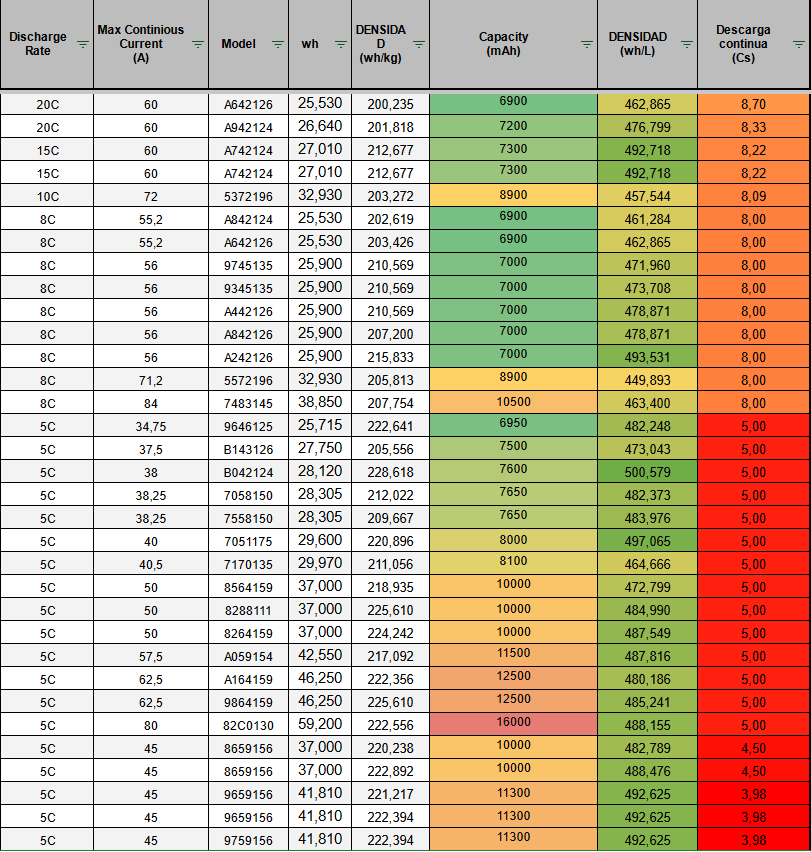

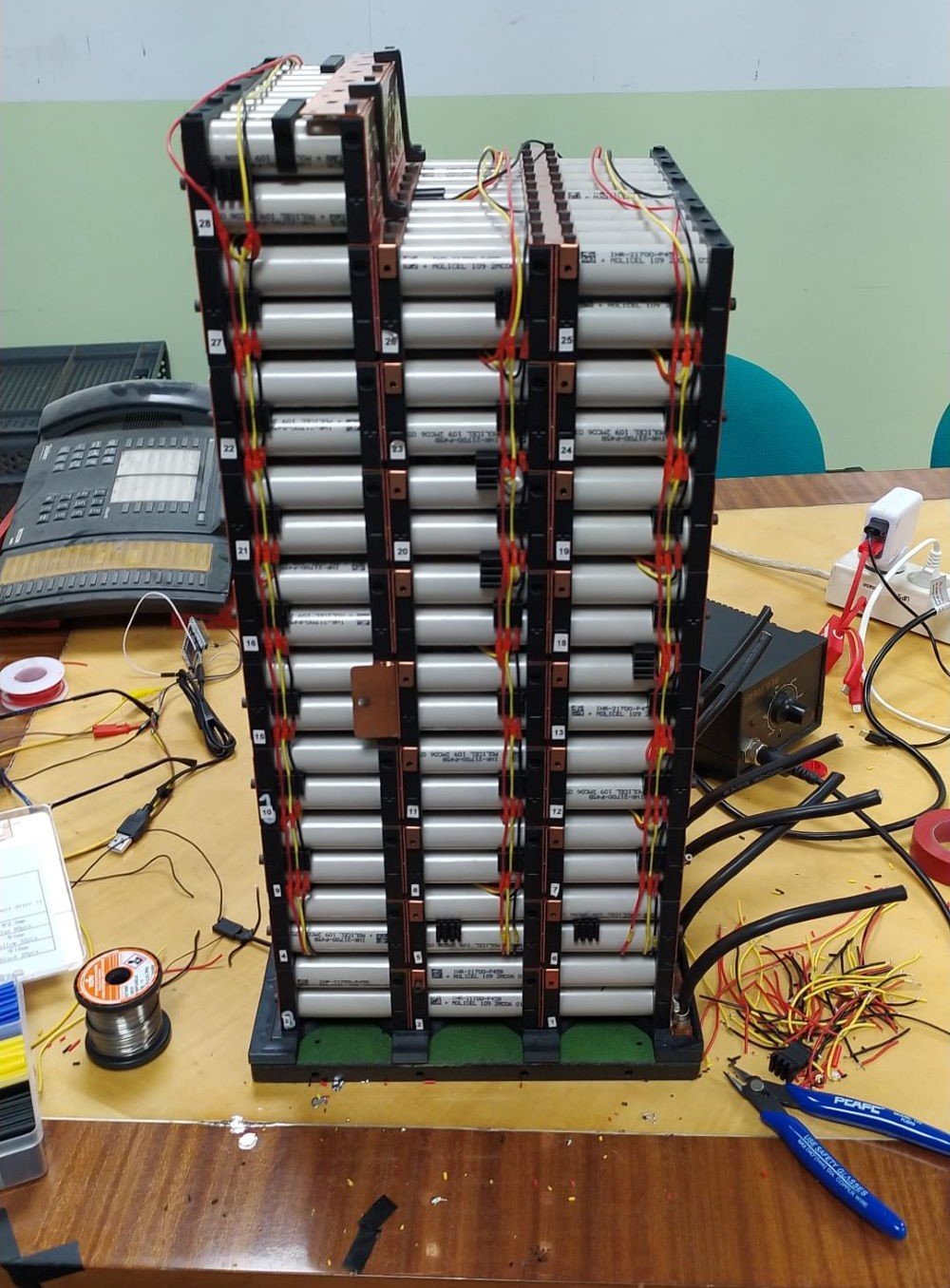

One of the many decisions that were done without a reason (or knowledge) was the battery package. This prototype had a Brutepower cells. The decision was taken because other teams had it on previous editions. This cells were Chinese 22.000 mAh cells of LiPo technology. They were mounted on a 24s 4p configuration. This means, 24 cells in series and 4 cells in parallel, giving a 88Ah and 100.8V on full charge. As we will see on battery section, this was a wrong decision as this cells are not suitable for this use.

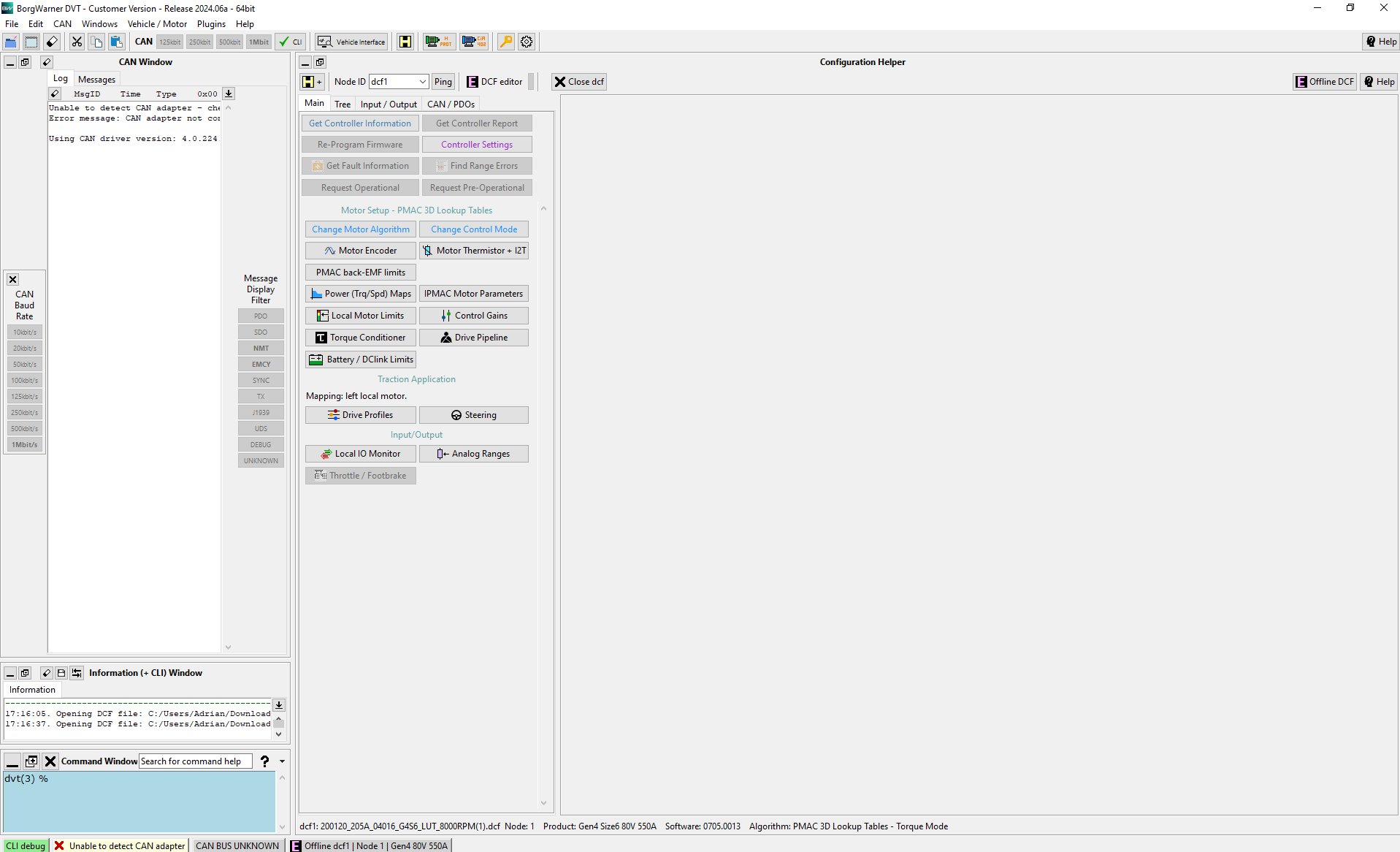

And of course, on that edition, inverter programming was stock. The organization of Motostudent sent us a programmed file (DCF) which wasn’t working correctly so the inverter was turning off repeatedly (overcurrent error).

Actual prototype

Finishing the previous edition I realized what a great contribution and opportunity this project could be for me. The material and resources we can access are something very expensive that would be almost impossible to do privately. This motivated me to take the reins of the project for this edition. As mentioned before, we started with no money so our first approach was to take some sponsors. I will speak about this shortly.

Sponsorship

We needed to sell something, a brand, a product, an idea. To do this we needed to have a portfolio to present ourselves to companies and obtain sponsorship. We begin by creating all the necessary material:

- Web page (www.uburacing.es)

- Portfolio

- Sponsorship levels

- Slides

- All documents necessary for showing the project.

The first thing everyone thinks is that we could have sponsors in exchange of visibility. We put a sticker on the bike and they give us money or resources to accomplish the project. The reality is that a project like this does not have the visibility that it should, so we looked for another alternatives.

Nowadays companies are very “committed” to society (Agenda 2030, SDG, etc.), so we tried to generate a discourse that was related to that. Burgos is a city with a lot of industry and it is also true that many people who have finished their studies leave the city, so we had the discourse we needed there (keep talent here).

Our main idea was “the talent of young people”. In a small city like Burgos, companies need skilled workers. This is the perfect project for people with special interest in technical field beyond university studies. In exchange, companies that support the project could get this skilled people to work with them.

Our main idea was “the talent of young people”. In a small city like Burgos, companies need skilled workers. This is the perfect project for people with special interest in technical field beyond university studies. In exchange, companies that support the project could get this skilled people to work with them.

Companies need to support this project to train emerging talent and prevent young people from leaving the city, as well as make their companies known between this young students. This is also something socially responsible for companies. We, in return, would deliver the resumes of the team members (although unfortunately we didn’t have many).

With everything ready, we started to contact everyone we could thought email, phone, meetings, etc.

One thing that worked very well for us was to going to events where owners / CEOs met. We were lucky to be able to show the project to this profiles on two “private” big events in the city. In addition, there, we could make direct contact with them and close a meeting to explain the project to them in more detail later. On the other hand, if they liked it, they could recommend us to owners from other companies.

Mainly, we had 2 types of sponsorship, economical and manufacturing. The companies that could manufacture something helped us with that (sheet metal, machining, materials), and the companies that couldn’t, helped us in the economical way (money).

Thankfully, we got all the budget, support and materials necessary to accomplish the project (around 30.000€), but not with too much time to finish it, so we started working in parallel on the technical field.

Someone will think, 30.000€ for a electric motorbike? Yes, because it’s not only the motorbike. We need parts for testing, spare parts, different sprockets and chains to play with, chargers for the batteries and also we needed to pay the administrative services for the association and, of course, taxes! And this budget is only for material, not including our working hours.

Technical challenges

The main challenge was that we didn’t have any idea about how to acomplish a project like this, so we started step by step.

The areas into which we divided the technical challenges were:

- Mechanics

- Chassis and swingarm design

- Fairing

- Electronics

- Electrical circuit

- Telemetry

- Powertrain

- Battery pack design and manufacturing

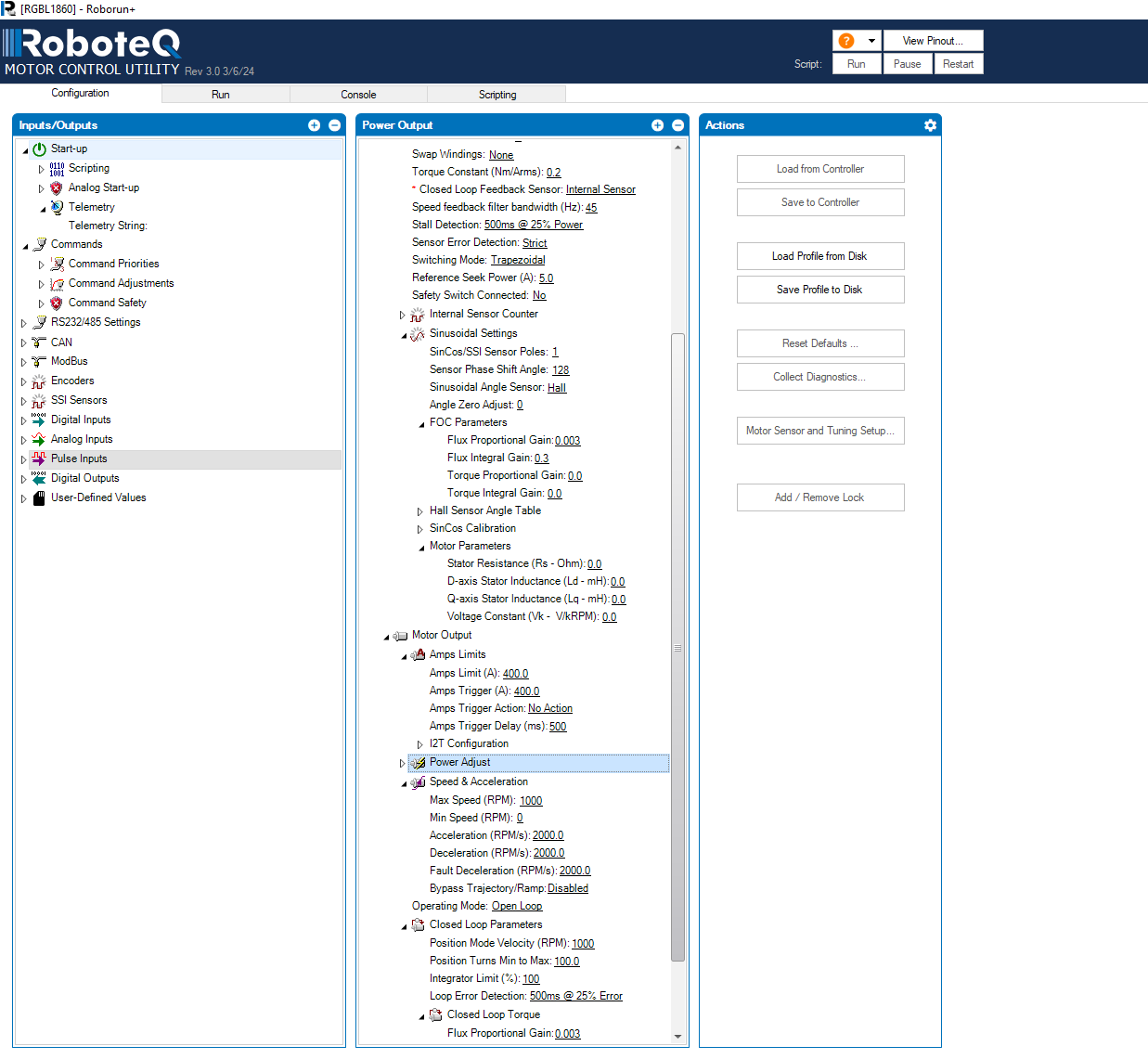

- Inverter programming

Each of these categories are composed by much more specific categories that we will dissect below.

Mechanical ⚙️

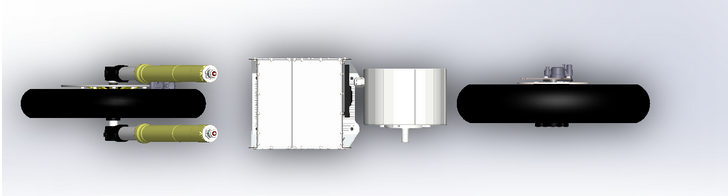

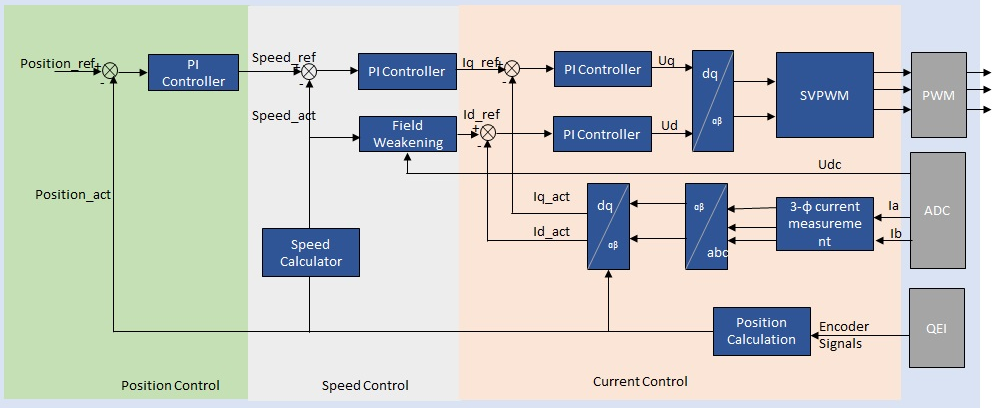

Dyno

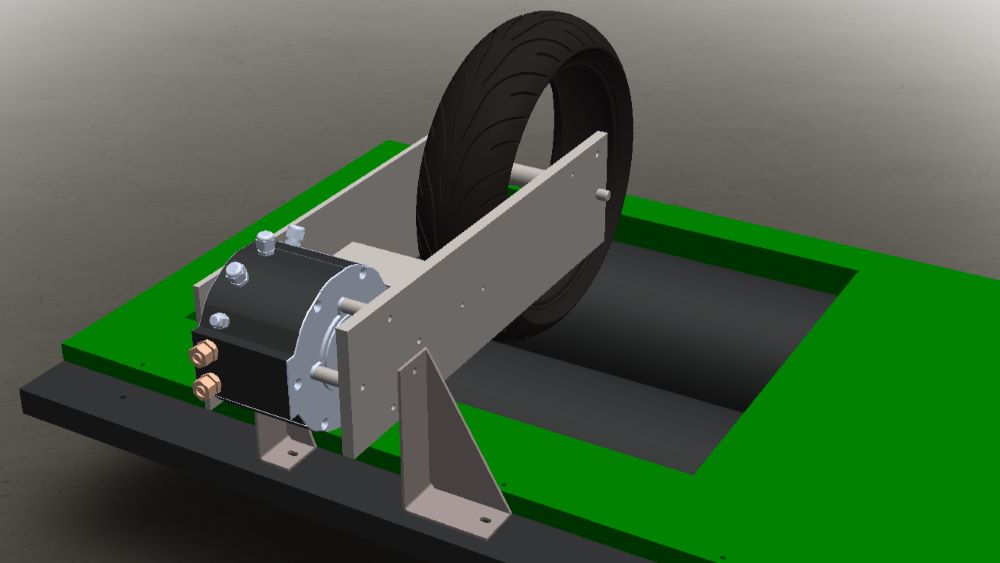

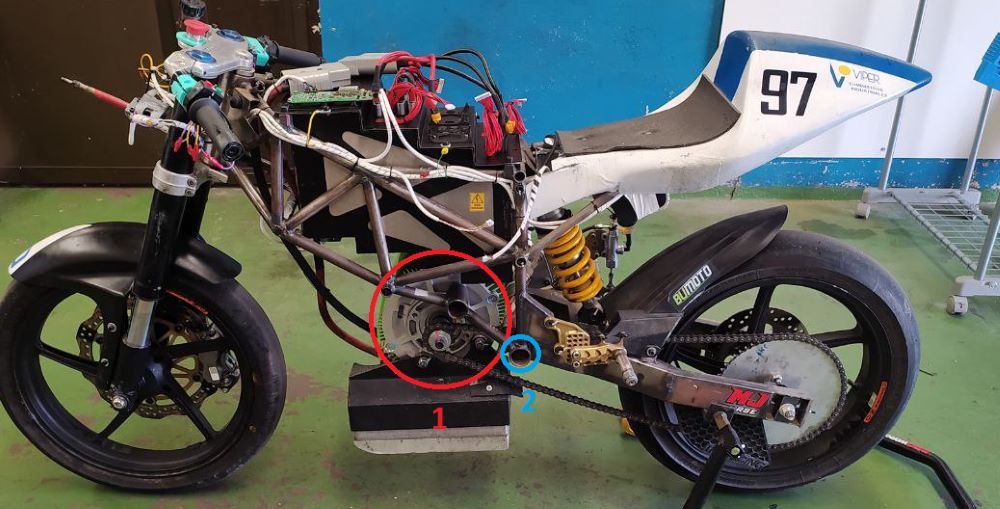

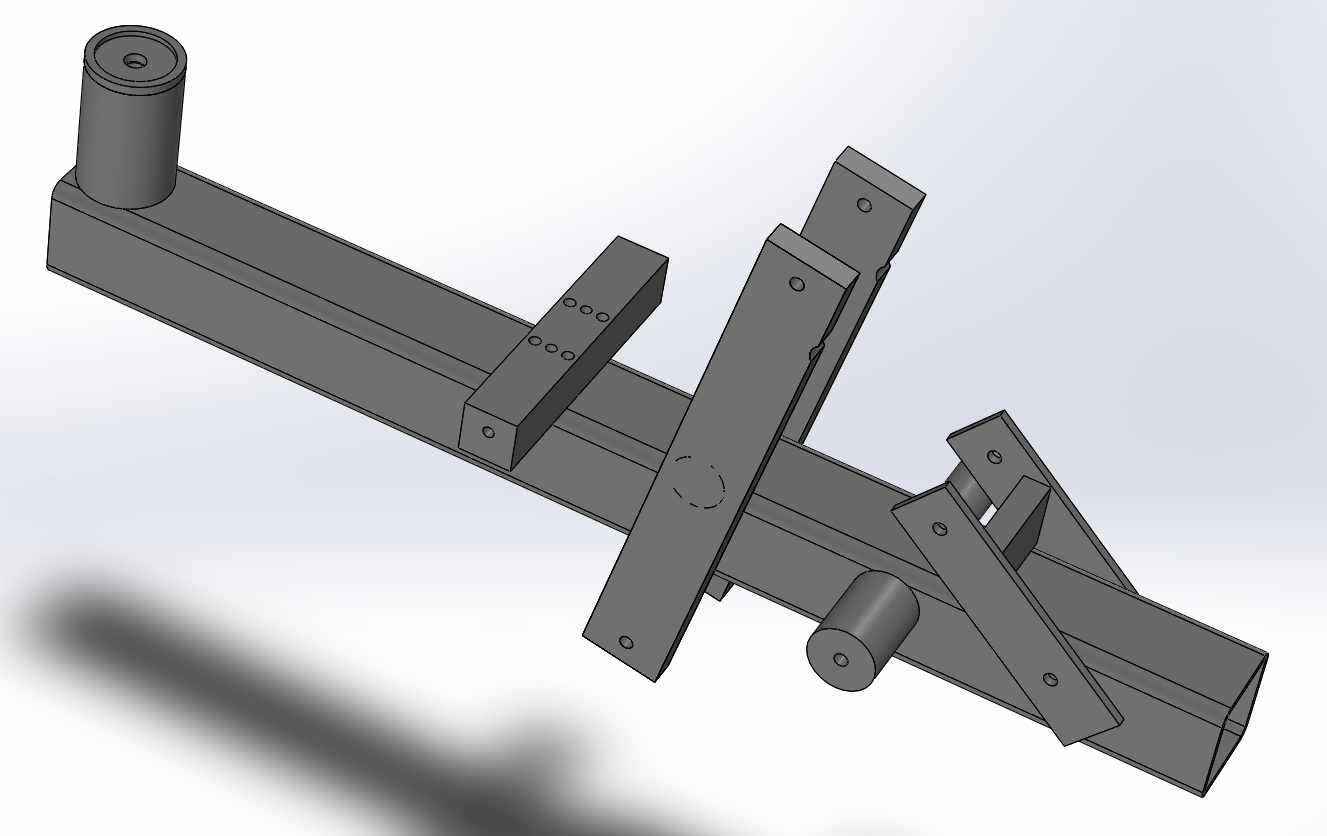

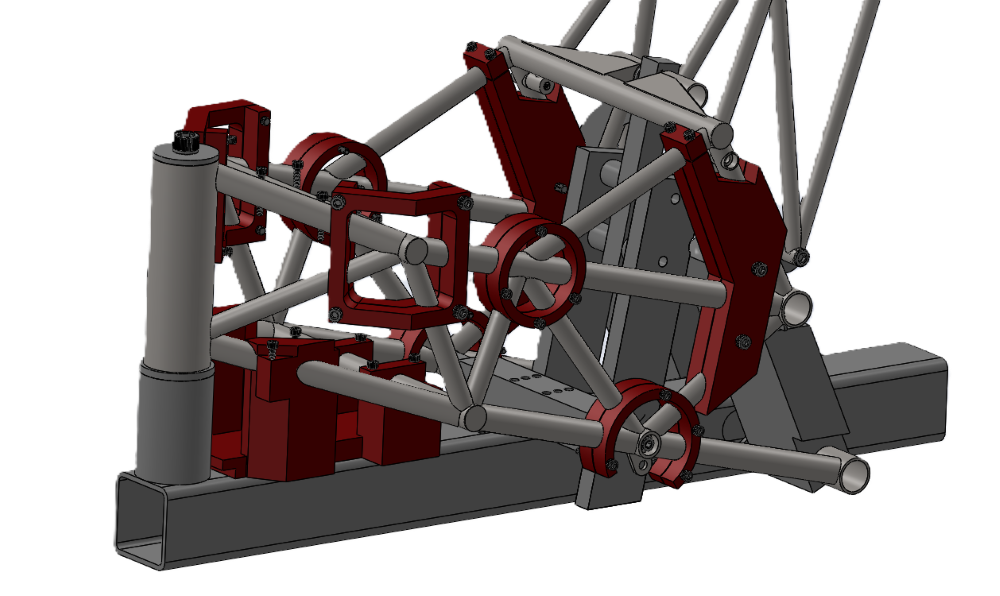

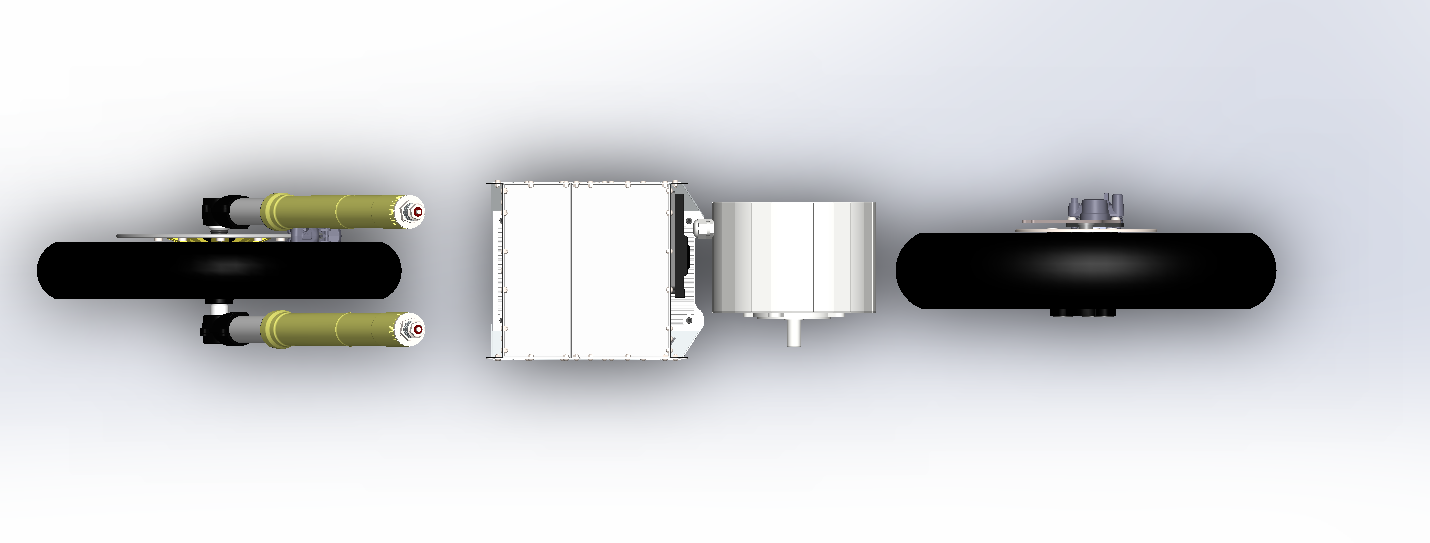

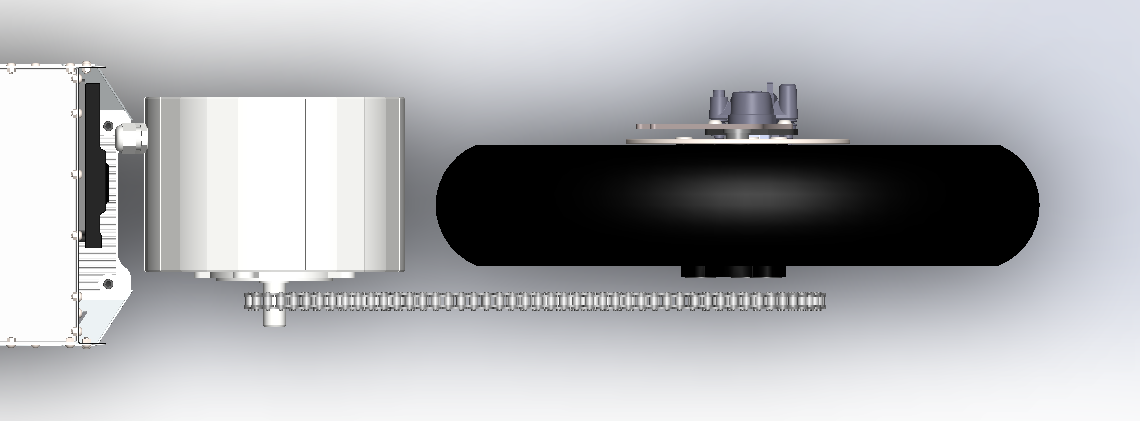

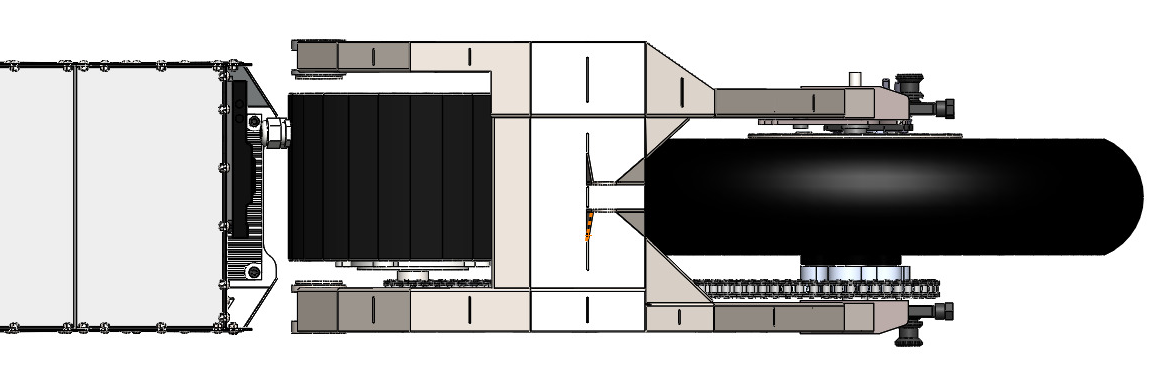

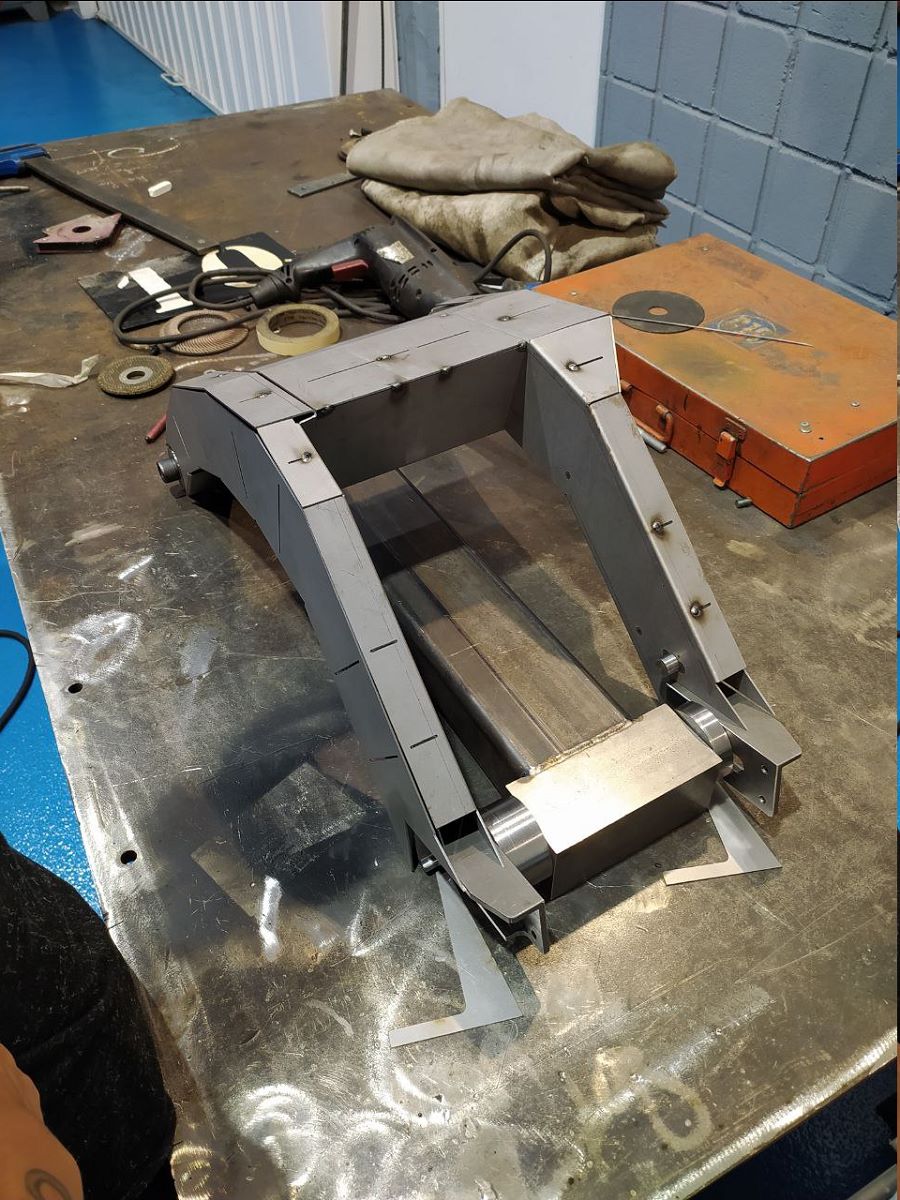

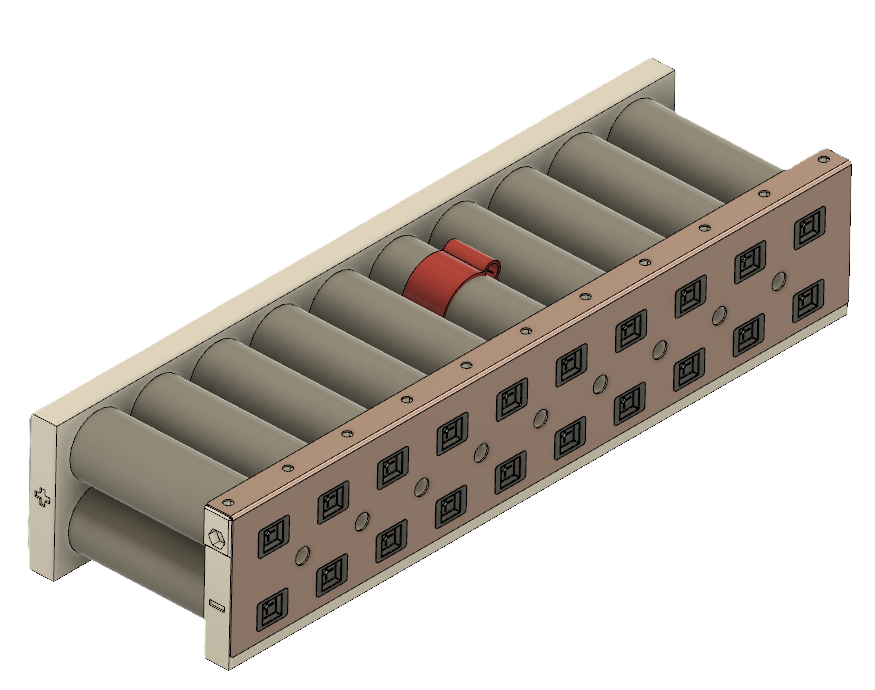

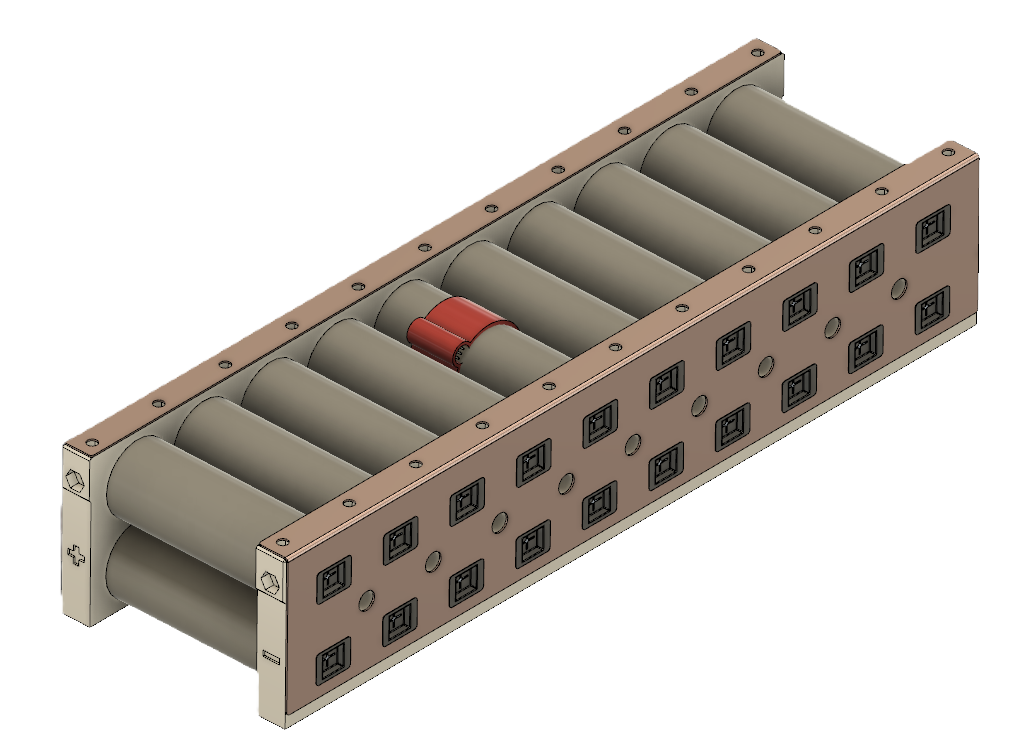

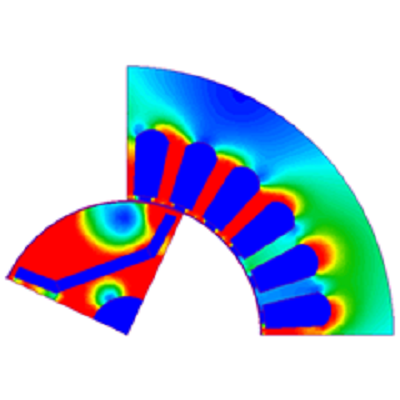

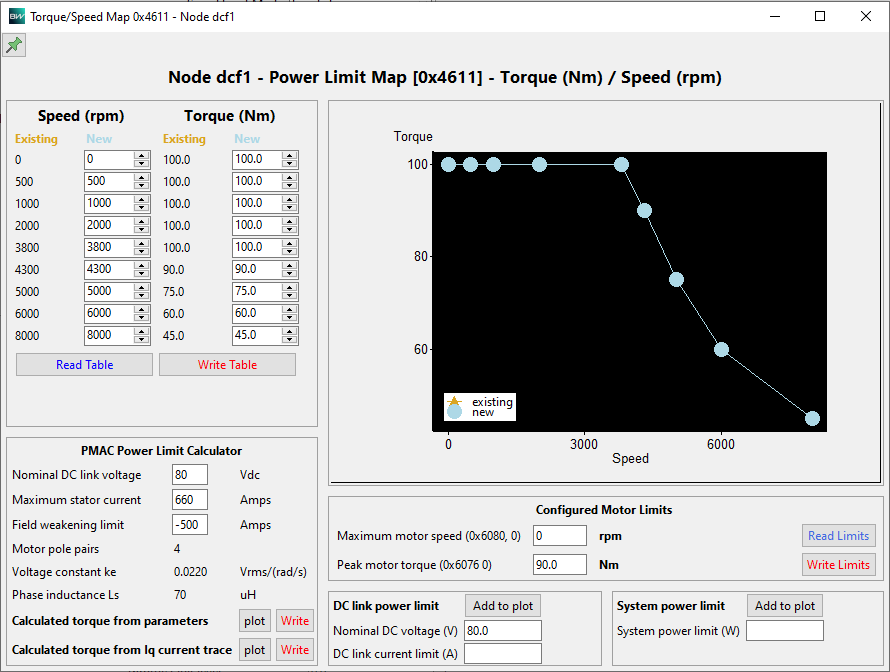

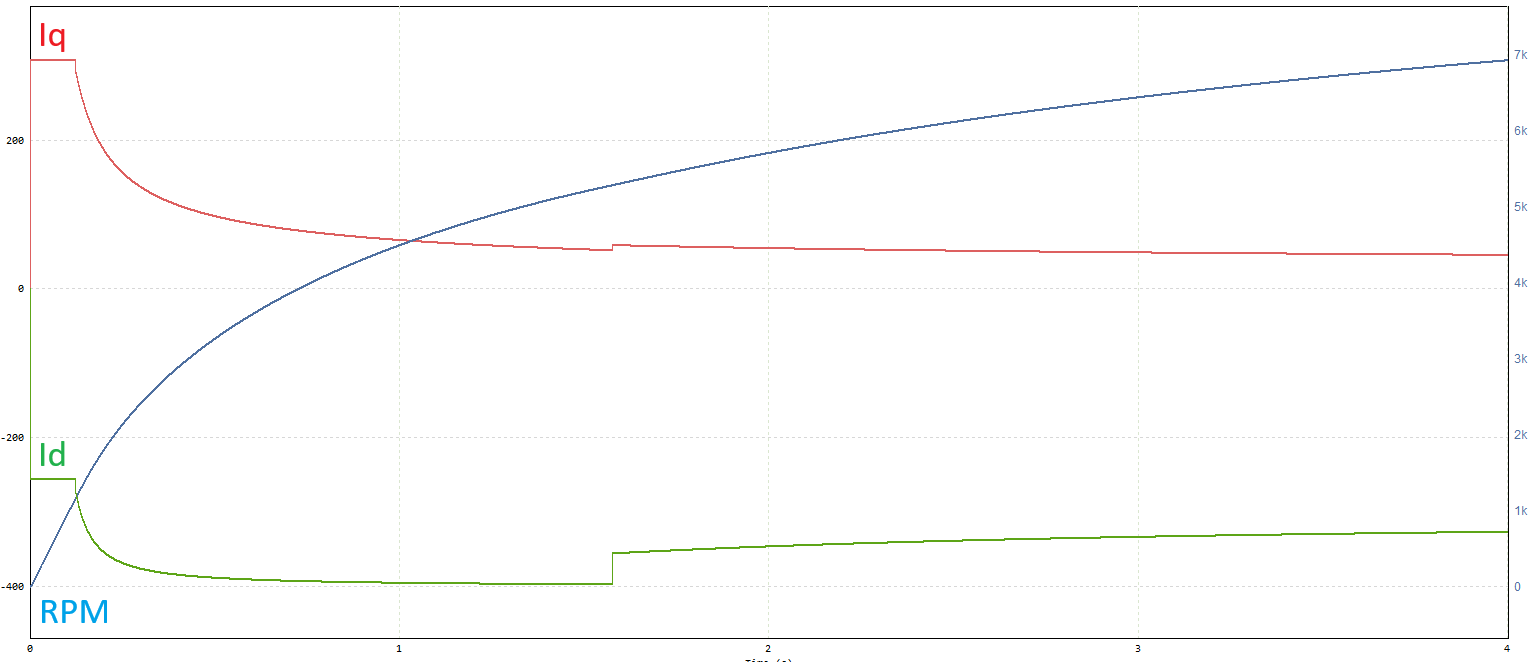

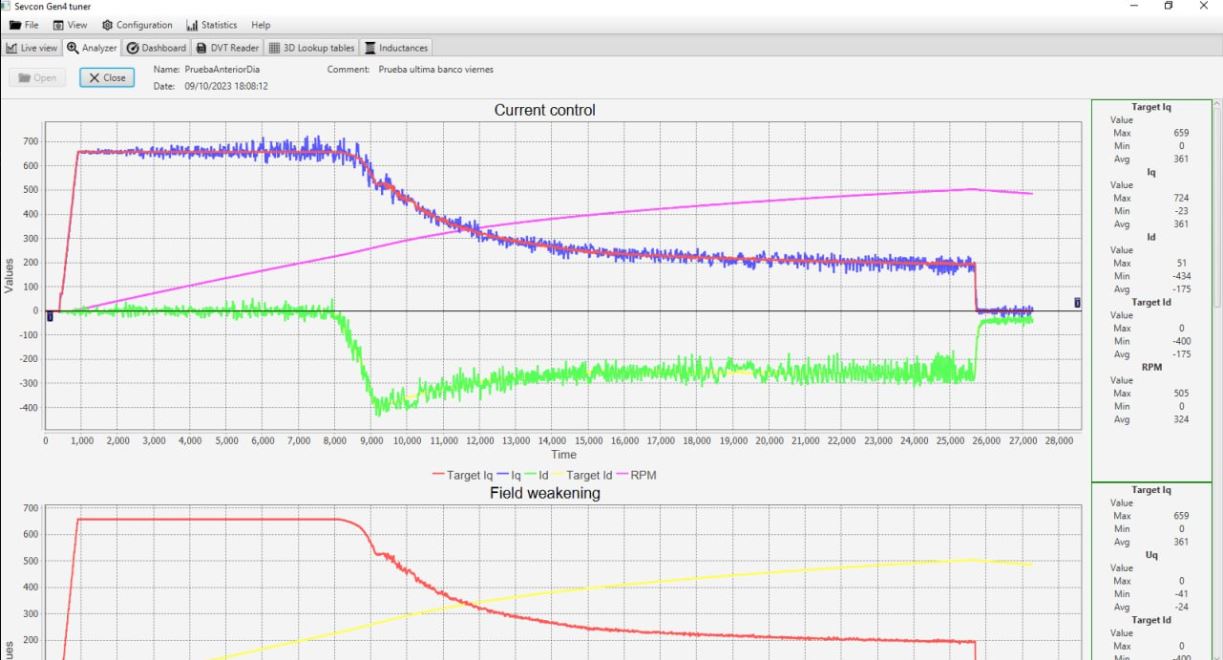

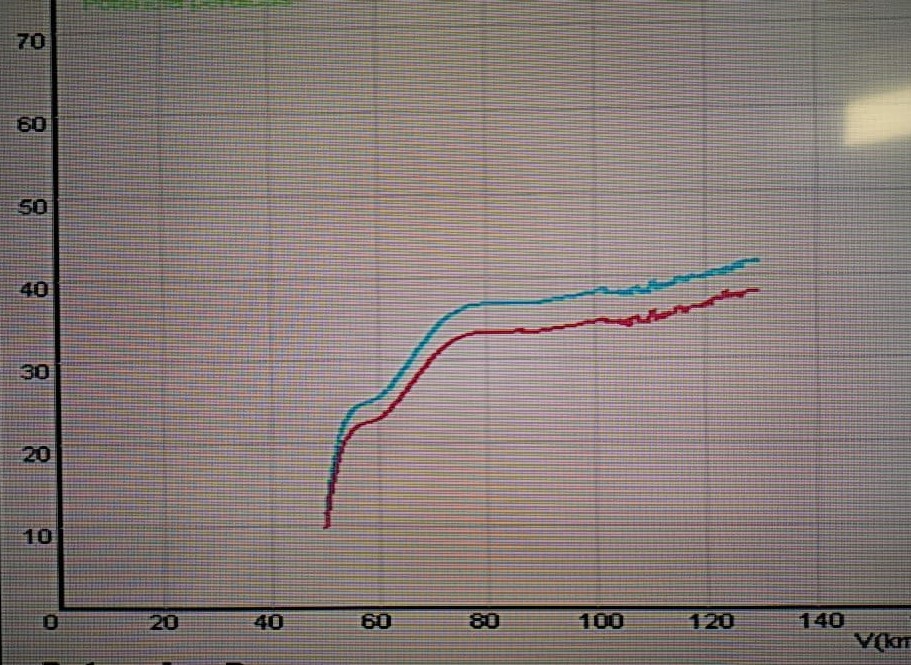

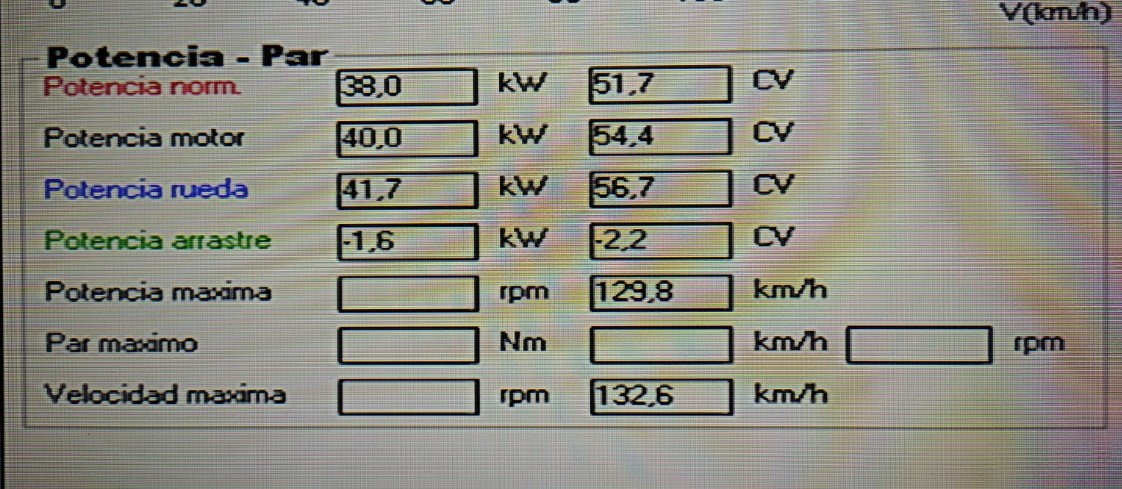

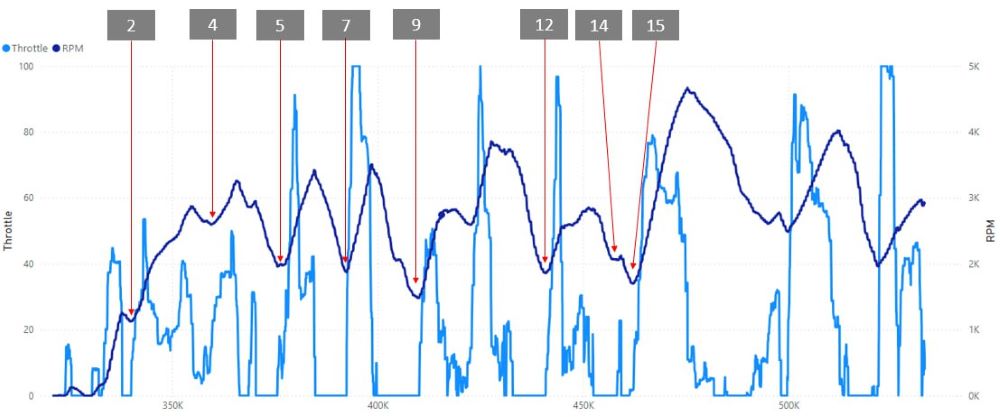

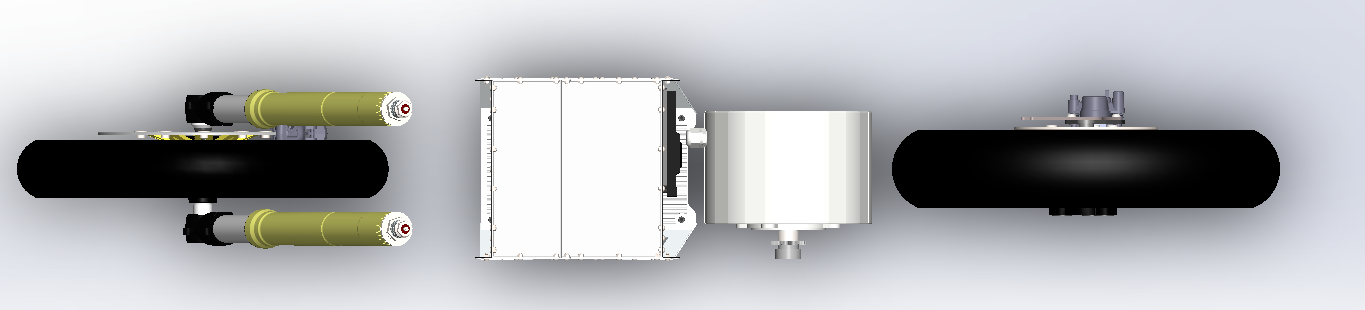

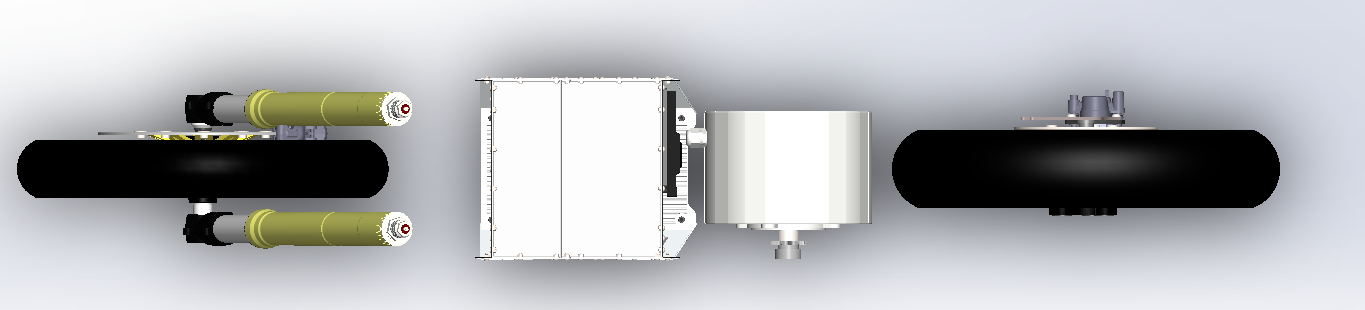

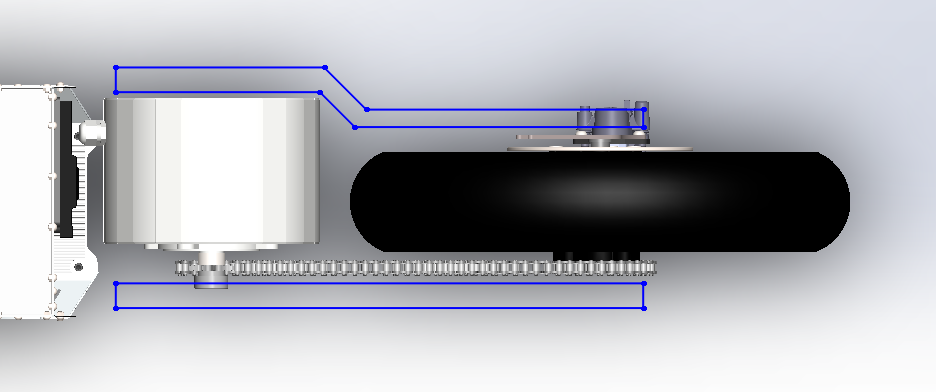

Although it’s not directly part of the bike, the first thing we did was to start the design of a support to mount the electric motor on a dynamo-meter (a sponsor allowed us to go to their facilities). As we will see later, the programming of the inverter is a fundamental task within an electric motorcycle, so we needed to be able to test the power given by the different changes we made to the inverter.

The dynamo-meter was ready to mount a vehicle on wheels, not with the motor directly with a chain for example, so we had to build something like a swingarm to be able to mount it.

To supply the inverter we used two lead-acid forklift batteries connected in series (96V nominal) as you can see at the back of the image, which allowed us to use the dyno for two or three hours continuously. With this we could start working on the inverter programming in parallel with the development of the motorcycle. The most important part of this step is that all the design will be conditioned by the work made on the dyno. Here we should be able to take as much power as possible from the motor with the lowest heat looses. Also we need to calculate the motor energy consumption to size the battery correctly. All this characteristics will be crucial to the correct design and decision making.

With this support manufactured, we could start with the design of the motorcycle meanwhile we work on dyno.

Front brake and forks

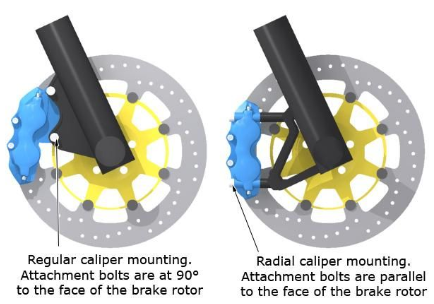

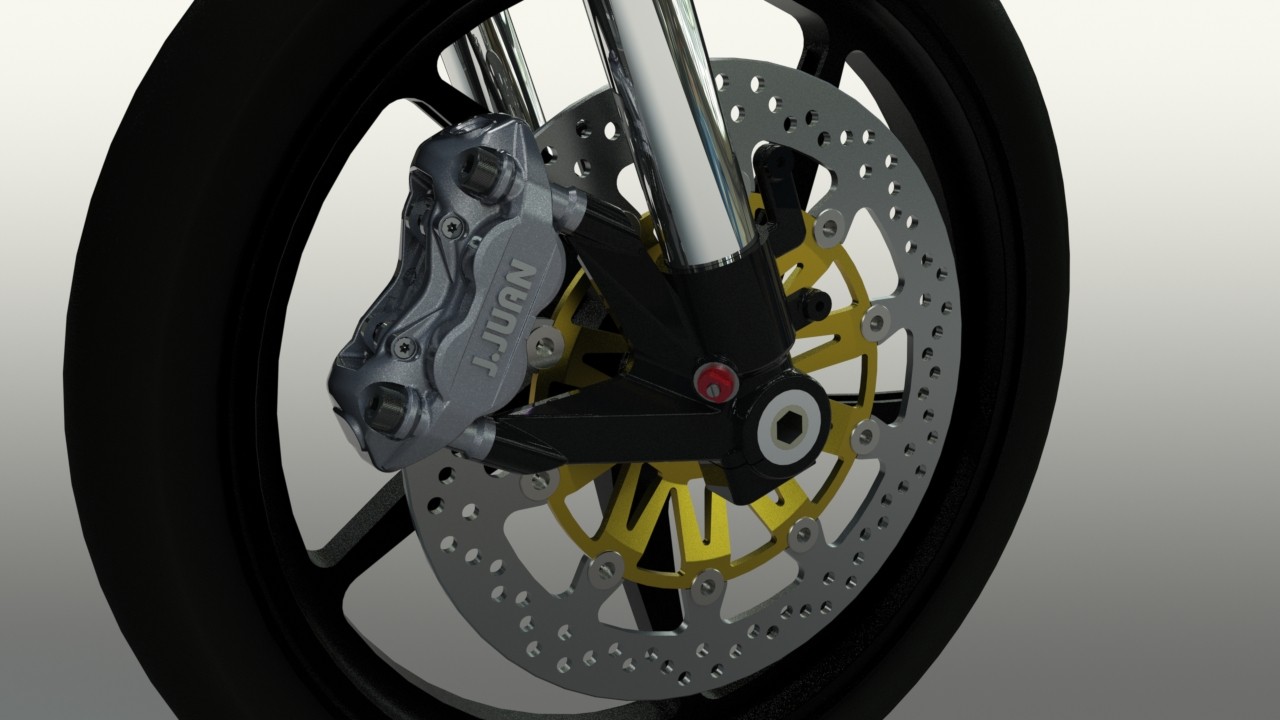

As mentioned previously, the organization gave us the front brake. We had a J.Juan front brake caliper of 4 pistons and radial mount.

Radial vs axial caliper mount2

Radial vs axial caliper mount2

There are two types of brake caliper mounting, axial and radial. The caliper we have for this edition is radial and in the market there are mainly two (there are more) standard distances between the bolts of a radial caliper, 108mm and 100mm. We had a 100 mm brake caliper. Why does this distance affect to us? Due to this non-standard distance.

Example of 100mm radial brake caliper3

Example of 100mm radial brake caliper3

There are forks with different distances between bolts, so we have three options:

- Manufacture a custom mechanized part to adapt any fork to our caliper.

- Find a front fork with 100mm between bolts.

- Find a front fork with 108mm between bolts and manufacture an adapter.

- Find a axial mounting fork and manufacture an adapter for the caliper.

First option is expensive for us, so discarded. The third option was attempted by previous teams, with an axial brake holder:

Example of 100mm radial brake caliper

Example of 100mm radial brake caliper

This looses all the benefits of a radial caliper, so let’s try to skip this time.

Japanese forks are cheap and abundant in the market. There are high quality forks with cheap prices. The problem is that most of Japanese motorbikes have a 108mm between holes. It’s a bit difficult to manufacture an adapter for this situation as there is no enough space for a clean anchor on the second screw (the one that is not aligned). Here there are some examples from other teams that adapted it:

This latest design by UPM is elegant but it’s built on an 84mm mount. These are usually racing forks and although they are the perfect option, this forks were very expensive for us.

The option of a 108mm fork could be a good solution. However, we were not completely convinced because the distance between the bolt holes is so small and 8mm is not enougth offset between caliper hole and fork hole for the bolt.

On the other hand, European forks are perfect (BMW, KTM, Ducati, etc.) because they use to have brake calipers with a distance of 100mm between holes. The problem is that most of them are from big engine motorcycles, which makes it larger and heavier, and the fork is too long for our prototype.

After hours and hours of searching, we were able to find that the only two forks that could be suitable for our prototype were one from a Triumph Speed Triple 675 and another one from the Ducati 848 Evo.

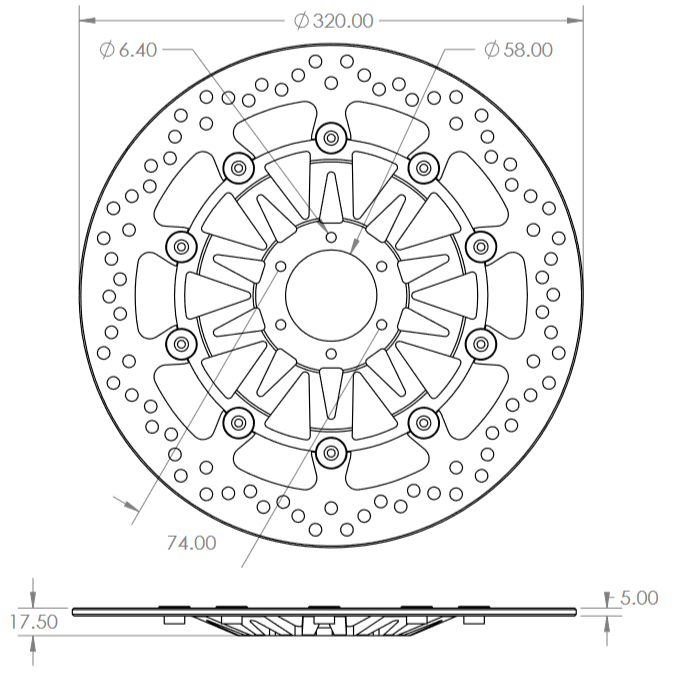

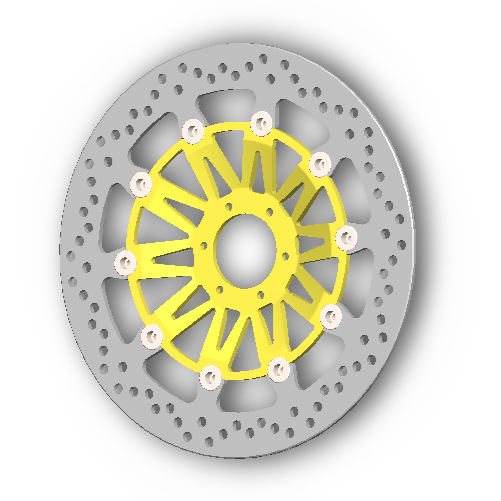

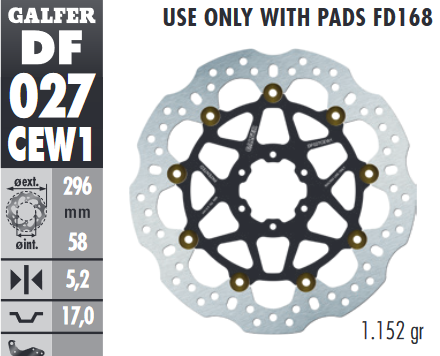

With this forks we have a new problem. These motorcycles had 310mm and 320mm diameter discs and there were no discs on the market that met these specifications for our rims, for which only 296mm discs were available. This means that if we mount that fork and caliper, the brake disc will be small and the caliper won’t bite the disc correctly.

Biggest disc for our rims in the market4

Biggest disc for our rims in the market4

After asking NG Brakes, we were able to get a custom build for our prototype with a 58mm inner diameter, 17.5mm rim cup and a 320mm disc. This means that we didn’t need to manufacture any kind of brake adapter. Also, with this design, we could mount the largest disc that fits on this rims (fixed by the organization as they give us the tires). We could say that we had achieved the most powerful braking system we could possibly create while also keeping design simple. This was reflected in the tests as we won the braking test over 45 teams.

With this brake disc ready, we selected forks from a Ducati 848 Evo. These Showa forks were an ideal for the prototype though they were slightly longer than what we initially aimed for. However, they worked well.

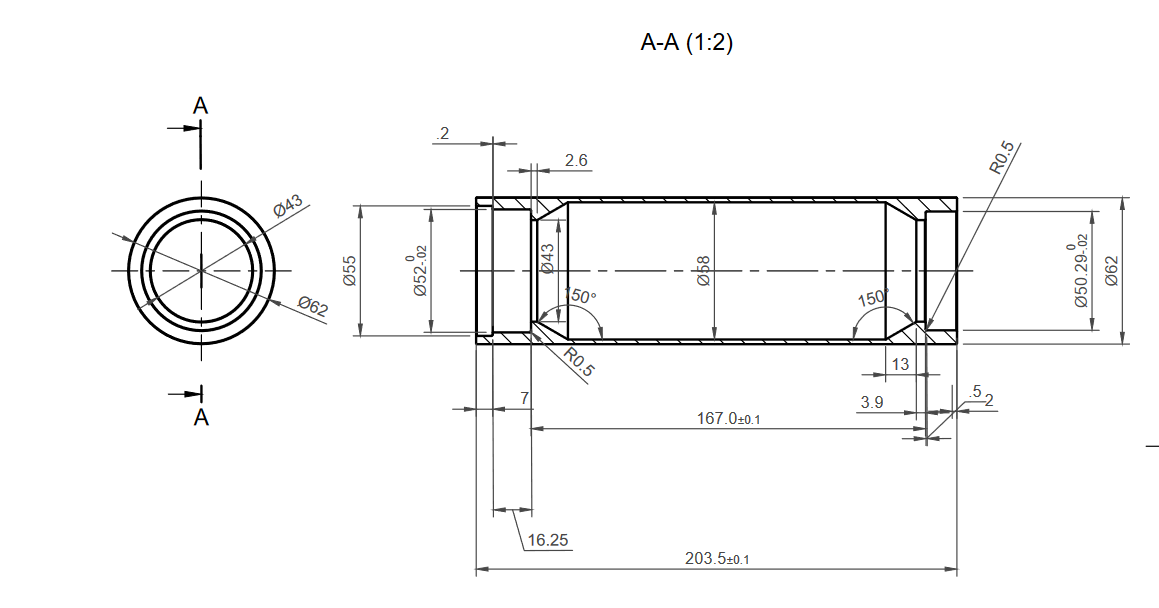

Front axis

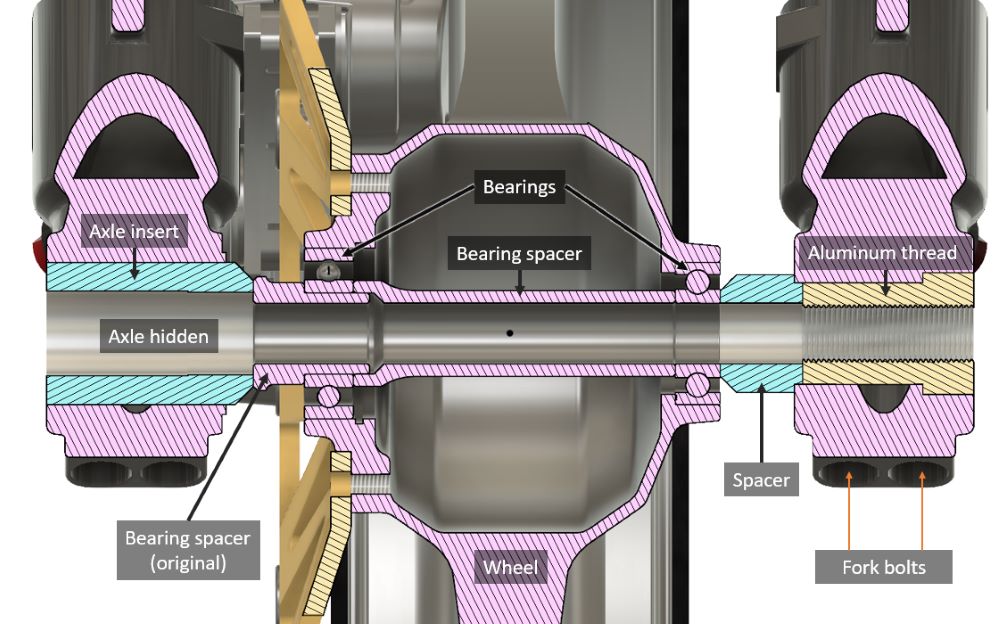

With the brake disc, rims and forks chosen, we could start the front axis design. It should be noted that part of this design is restricted by the lower shape of the forks since they are commercial parts that we are not going to modify. It should also be noted that we were looking for a cheap and simple design. We didn’t need to quickly assemble or disassemble the front wheel at any time so the design was not focused on that feature.

For the design of the front axle, the order and restrictions applied to the 3D design were:

- Centering the front wheel axle with the front bar axle supports (concentric).

- Mounting the front disc on the wheel

- Mounting the brake on the right fork bar.

- Alignment of the brake pads with the brake disc.

- Symmetry of the left bar with the right bar with respect to the central plane of the wheel.

With this distribution we are ready to design the bushings and the axle.

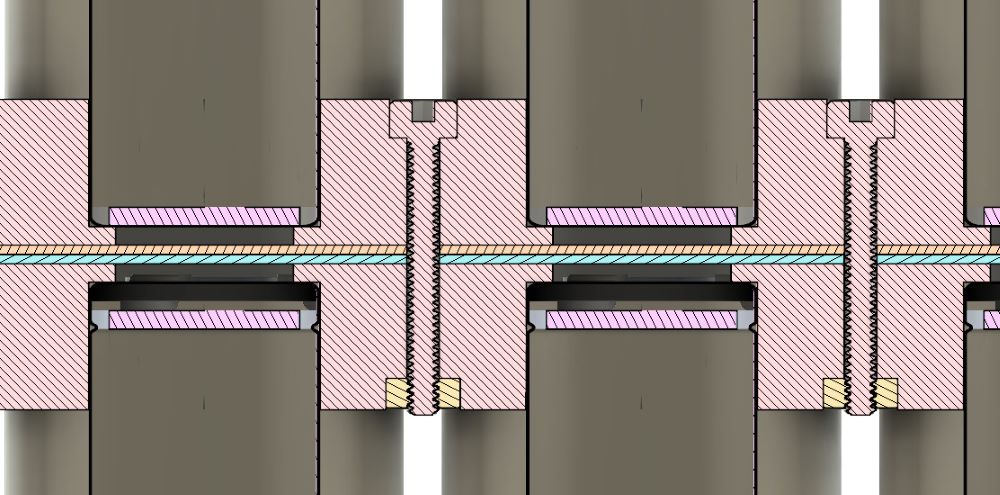

Front axis section view (hidden axle screw).

Front axis section view (hidden axle screw).

To begin, we need to examine the counterbore that exists on the right fork (shown in the image). This feature indicates that we can use this side as a tightening point for the assembly we are building with all the bushings.

The most technically correct design might have been to use a nut on the right side of the axle instead of tightening directly against the bushing (the yellow one). This would allow for a more secure tightening, but it would result in a less refined design, as the axle is limited to a 15mm diameter (due to the rim bearings).

It’s important to keep in mind that in this type of design, you should never tighten one fork leg against the other. The assembly should be compacted against one fork leg, with the other leg securing the axle in place based on its required position.

From right to left in the design, we start with a bushing (the yellow one on the right side), which will serve as the thread on which the entire assembly will be tightened. Due to the counterbore in the fork leg, this bushing will not be able to move to the left, effectively acting as a nut for the axle. Additionally, the fork legs will secure this bushing using two screws at the bottom, keeping it locked in place.

Next is the blue bushing, which works as a spacer between the rim and the fork. This distance is determined by the symmetry of the fork legs in relation to the wheel. The bushing is slightly inserted into the fork leg to center the assembly, making it easier to mount, and it also acts as a stop in the opposite direction, preventing movement to the right when the axle is tightened.

Afterward, we have the wheel bearing, an inner spacer, and the other bearing, followed by the final purple bushing, all of which are part of the original rim assembly.

Finally, we reach the blue bushing, which compensates for the difference in diameter between the fork and the axle. In this case, we used a 15mm diameter axle due to the wheel bearings. The original forks had a larger hollow axle, so we needed to supplement it. We adapted a factory axle from another motorcycle model by cutting it to the correct length and threading it to fit our prototype. That’s why the blue axle insert has its specific diameter—it matches the head of the axle we used.

When tightening it, the head of the axle will press against the left blue bushing (note the small counterbore), followed by the pink bushing, the next blue bushing, and the yellow one. This creates a compact assembly that is completely tightened against the right fork leg.

Finally, we tighten the left fork leg by securing it around the blue bushing, ensuring that the entire assembly remains in place. This process ensures the forks are perfectly parallel and properly aligned.

As for assembly, the tightening order would be:

- Lower screws on the right bar

- Axle insertion

- Lower screws on the left bar.

Note that if, on the other hand, we tightened the screws on the bars on both sides and then the wheel axle, the bars would tend to form a bundle between them and would not be completely parallel.

On the left of the image we can see the incorrect assembly of the front axle. This will cause the forks not to work parallel, causing malfunction and, in the future, a failure. On the other side, in the right assembly we can see how the axle is packed with the right bar and the left bar bites the axle in the natural position.

On the left of the image we can see the incorrect assembly of the front axle. This will cause the forks not to work parallel, causing malfunction and, in the future, a failure. On the other side, in the right assembly we can see how the axle is packed with the right bar and the left bar bites the axle in the natural position.

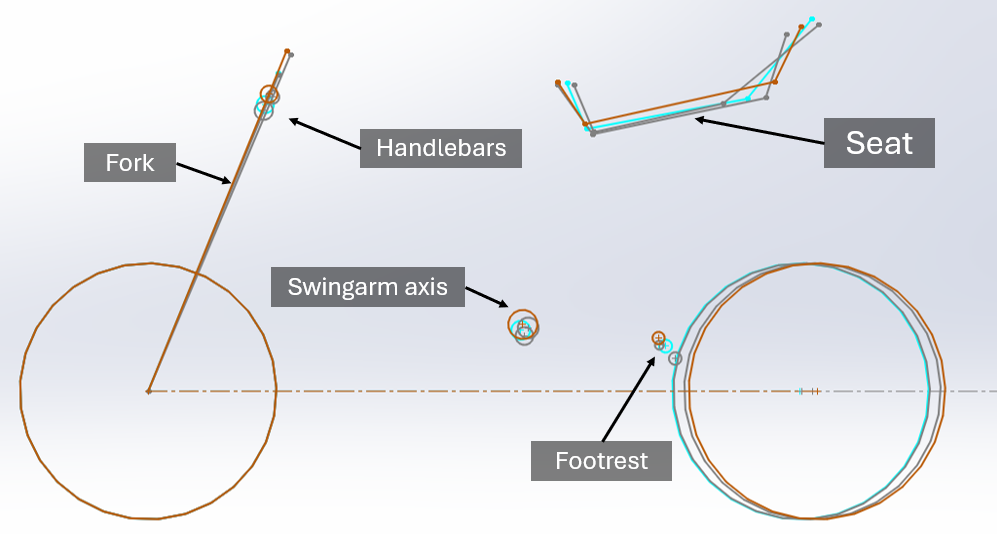

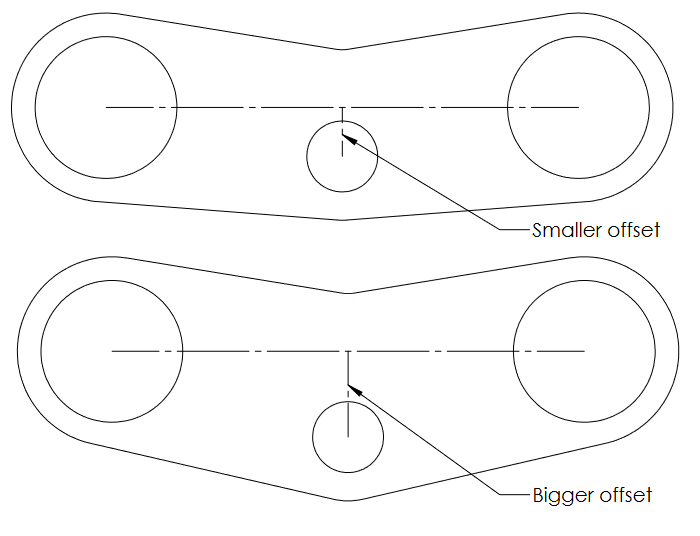

It’s also important the fact that we have modified the distance between the bars that were not from this bike. We will not be able to use commercial triple clamps, we will need to design and manufacture our own since the distance between the bars is completely different to the bike that had these bars. If we use standard triple clamps, the bar opposite the brake caliper would not be symmetrical about the center of the wheel, which would result in the prototype having the front wheel not aligned with the center of the steering axis. On the other hand, making our own triple clamps allows us to work on the geometry and make them with the offset we want.

Playing with this offset give us different geometries and different prototype behavior.

Playing with this offset give us different geometries and different prototype behavior.

This offset distance, as we will see later, will also influence the behavior and handling of the bike. With the front end sorted, it was time to start working on the geometry of the prototype.

Component placement

Analyzing previous prototype

On previous edition, the bike geometry and components position was quite simple. The electric motor was in the same position as a petrol engine should be. Batteries are on the top of the motorbike, where the fuel tank should be. This is a lazy design has two main inconvenient:

1. The chain is too long

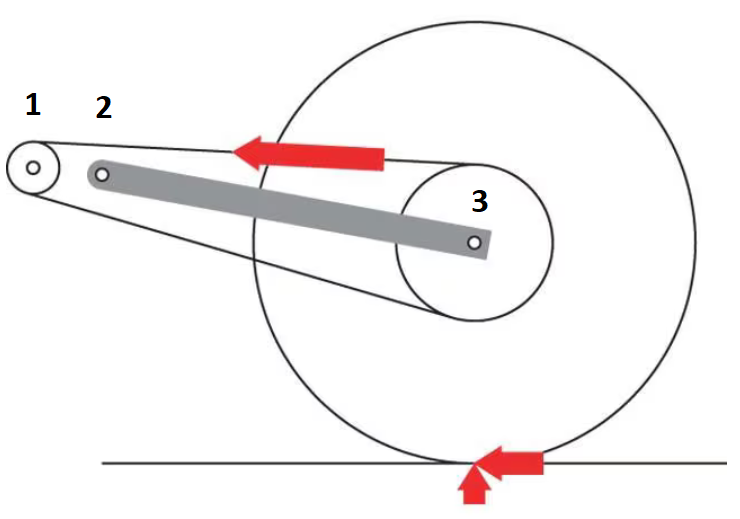

Normally, on a motorbike we have the current disposition:

The engine output (1) is as close as possible to the swingarm pivot (2). This is because two main reasons:

- The chain should be as short as possible. It is a moving mass (an inertia) and that is not good for the behavior of the motorcycle.

- When the swingarm pivots, the distance between the point 1 and 3 (the chain length) changes. As close as we could keep the engine output to the swingarm pivot, we will minimize the length change.

With this arrangement, the chain tension varies as the wheel pivots.

With this arrangement, the chain tension varies as the wheel pivots.

On petrol engine, this is not a problem because the diameter of the output shaft of the gearbox is small, so we can place the output (1) and the swingarm pivot (2) very close.

This is not possible with an electric motor. It has much higher diameter:

2. Batetry weight is high

With the battery in that position, the center of gravity of the bike (COG) is very high. This means, when you lean in a corner, it’s more difficult to put the bike straight again, it tends to fall.

Looking for the best design

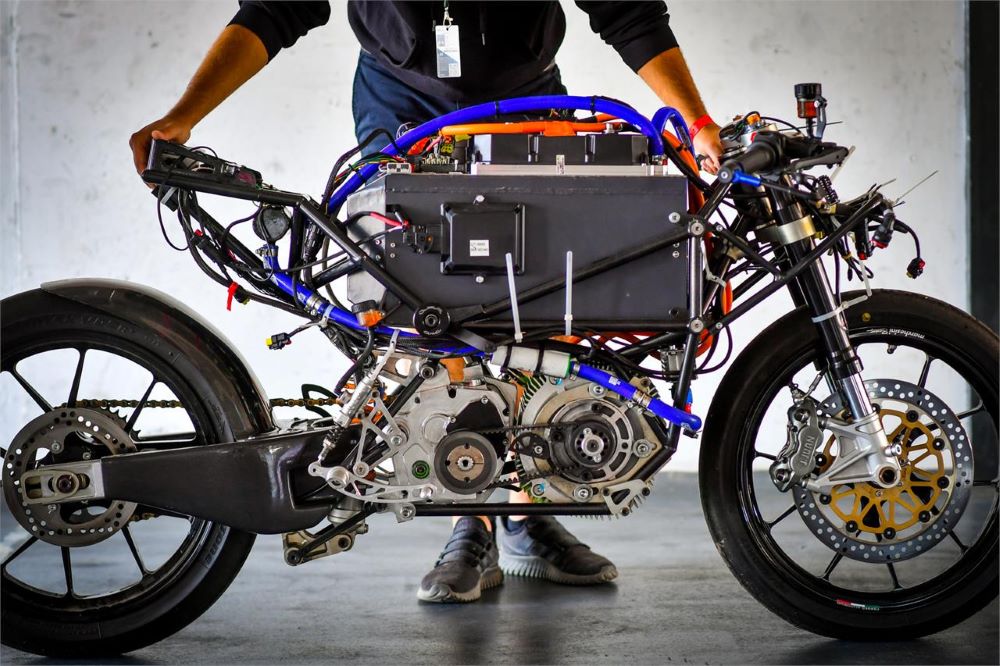

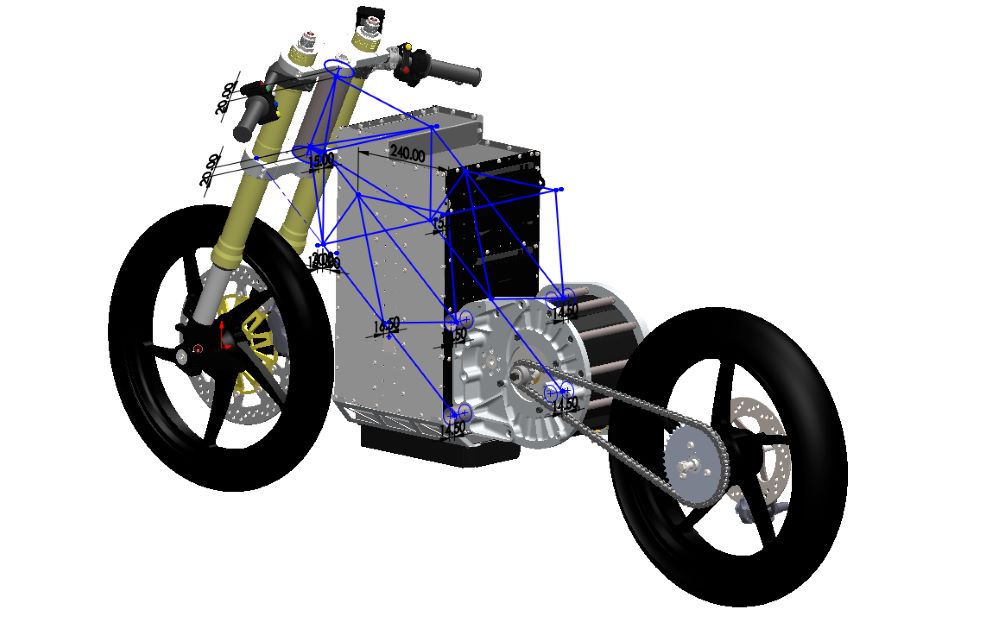

We had clear for the new prototype that there are two components that are important to fit in the correct place because of his weight and volume: the motor and the battery.

The battery is supposed to be bigger (we had a new motor, water cooled), so the volume and the mass was gonna be bigger than the motor. Also, with the battery it’s possible to fit some spaces or give it the shape that we need. That’s impossible with the motor.

Analyzing motor position

We thought about two options for the motor keeping the shortest chain:

Make a chain forward

This means that the chain that transfers power to the wheel is not directly connected to the motor. There are one or more intermediate shafts.

For example, as Energica MotoE:

Energica MotoE transmission. It has intermediate gears to connect the chain output shaft to the motor.

Energica MotoE transmission. It has intermediate gears to connect the chain output shaft to the motor.

LEM Wroclaw prototype. There is a shaft between electrc motor output and wheel.

LEM Wroclaw prototype. There is a shaft between electrc motor output and wheel.

The forward can be done by chain, belt or pinions. This gives three advantages:

- The output axis has smaller diameter, which helps to achieve shorter chain.

- Allows to pivot the motor to a lot of different positions such as upper to the axis output or in front.

- Allows to gear reduction. Normally this small electric motors work at high rpm (up to 8000), so if you have a direct transmission you need a big crown. With this gear reduction you can mount a smaller crown.

Place the motor inside the swingarm

It doesn’t mean to fix the motor to the swingarm. We need to keep moving parts as light as possible. We were thinking about something like this:

Zero motorcycles motor position |

Zero motorcycles swingarm. Output shaft and swingarm pivot are aligned. |

As you can see, the motor output is in the same axis as the swingarm pivot. This is possible with an aluminium mechanized swingarm, but we wanted to make the swingarm with sheet metal as it’s cheaper and easier to manufacture it with our resources. This is also not the best option for anti-squat geometry as we will see ahead.

Analyzing battery position

The other important element is the battery. We wanted to keep it as simple as possible. This means, that if we can, we will build a cube to enclose it.

Due to lack of time, we needed some quick ideas for the design. After a lot of research we got some ideas from other teams. In general all prototypes converge on two designs:

Battery on top of the motor

UMA Racing Team 2019-2021 3D model

UMA Racing Team 2019-2021 3D model

UJI prototype of 2019-2021 edition

UJI prototype of 2019-2021 edition

This is probably the most traditional design, the one that had been used in the previous edition. It looks a lot like a petrol motorbike in which the tank (in this case the battery) is located above the motor. As you can see, there is a big cube on the top of the bike. It keeps the battery access very easy but we had to deal with a lot of empty space in front of the engine. This year the motor was water-cooled so we didn’t need to keep a direct air flow to it.

On the other hand, this design raises the center of gravity of the prototype a lot. The electrical calculations that we made gave us a larger battery than the previous edition so this design was probably not the most appropriate.

Battery in front of the motor

The other design was something similar to Zero motorcycles, keeping the motor between the swingarm and the battery. The problem with this design is that if a motorcycle were to be manufactured with a traditional layout, the prototype would be too long, which would worsen its agility in curves or low-speed maneuvers.

After analyzing prototypes from previous editions, I found a pattern or idea that could be developed. Introduce the motor into the swingarm to be able to make a shorter motorcycle. With this layout we do not lose the space that is limited by not being able to bring the swingarm pivot closer to the motor axis. Note that the design is not exactly equal to the Zero motorbikes. This one has the axis in front of the motor output shaft.

2018 prototype of Guepardo Team from UMH

2018 prototype of Guepardo Team from UMH

2018 prototype of Guepardo Team from UMH

2018 prototype of Guepardo Team from UMH

We thought this design was better for keeping the COG low and chain length short, so we started working on it. Our idea was to use the motor as chassis as we have it there.

Geometry

Introduction

Maybe it sounds strange, but when you start drawing the prototype in the CAD software, a question arises, Where do I put the rider’s seat? And the footrests? What rake angle should I use for the fork? And what about the swingarm pivot point?

The book MotoGP Technology5, by Neil Spalding, explains the history of different MotoGP teams in the world championship since the arrival of 4-stroke engines. After reading the evolution of motorcycles from different brands such as Ducati, Honda, Yamaha or Suzuki, it is possible to understand the complexity of a motorcycle chassis. Neil Spalding perfectly explains the amount of testing that was carried out, bringing up to 3 chassis or different swingarms in a weekend to be tested and discarding some of them after just a few laps on the circuit.

Speaking about the chassis, the lateral flexing that the front end of the bike may have in a corner is not the same as the one that the rear end has. There are many parameters that vary the behavior, such as the wheelbase, the length of the chassis, the length of the swingarm, where the welds are made, flexing in different areas, the height and position of the rider, angles of the geometry such as the angle of the front fork, the position of the rear shock absorber and more. The problem is not only understanding all of this separately, the problem is understanding how each of these changes affects the behavior of the complete motorbike. To give us an idea of the complexity involved, racing bikes have different non-welded parts to be able to vary the geometry without having to manufacture a new chassis or swingarm. It has been proven that these joints negatively affect the dynamics of the bike, producing chattering (vibrations of the bike that appear at specific frequencies) between other problems. For this reason, some riders preferred to use the bikes with these welded and fixed elements. Reading all this characteristics made me feel that even the most advanced teams in the world with multi-million dollar budgets often did not know very well (or did not obtain the expected results) what they were doing. All this after many years of research. In some cases, even by trying radical ideas (changing geometries, heights, positions of the pilots etc.) they managed to achieve new lines of work that worked much better than those they had been working on.

My conclusion after all this was that the chassis was one of the parts of the prototype on which we had the least time to waste, since we were not going to have the resources, knowledge and time to be able to evaluate all these aspects of the prototype. In addition, everything I mentioned above pertains to MotoGP, bikes that reach speeds above 300 km/h and with close to 300 horsepower. Without being able to confirm whether it is my idea or not, probably all these parameters affect less a bike with less weight and power as would be the case with ours (it doesn’t mean that it doesn’t affect).

Basic geometry

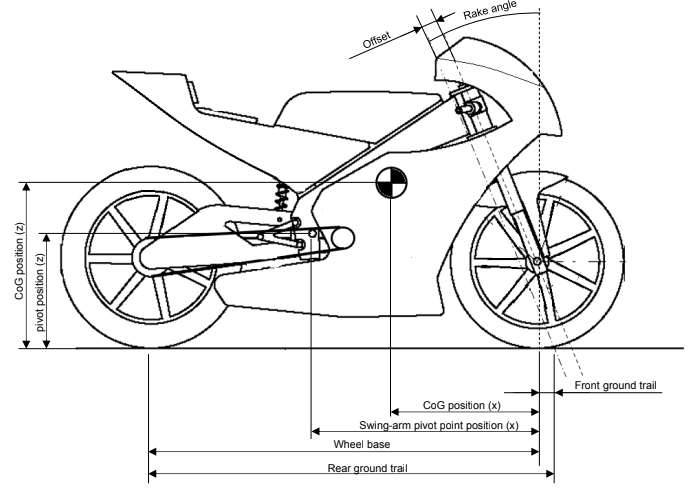

There are some basic measurements that must be established when designing a racing bike. These measurements directly affect the geometry and performance of the bike.

- Wheel base: Distance between the front and rear axles. A bike with a greater distance will be more stable on straights (high speed) but less agile in corners and slow zones. Having a greater distance will make the bike tend to wheelie less (with the little power that these bikes have, it doesn’t affect us too much) and the rear end will tend to lift less when braking.

- Rake angle: Angle between the vertical and the fork. Directly affects the trail.

- Offset: Displacement between the pivot point of the front axle and the axle of the same. A non-parallel offset could be made, although it is normal for them to be so. Racing bikes have non-welded elements that can be easily replaced to vary these measurements.

- Front ground trail: It’s the distance between the contact point of the wheel on the ground and the point where the line of the ground crosses the axis of rotation of the handlebar. This geometry is given by the angle and the offset. Generally, if we increase the rake angle we will make a more stable bike but more lazy in corners. If, on the other hand, we decrease it, we will make a very agile bike but very nervous at the same time and not very stable at high speeds.

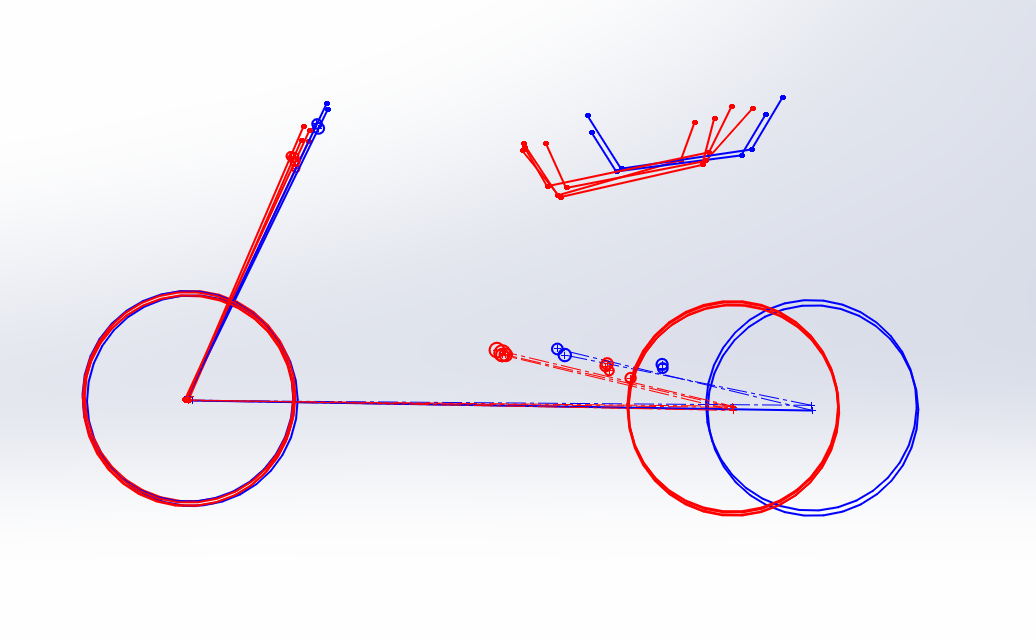

I remembered that a MotoGP engineer told me that they don’t leave the motorbikes with the steering straight when the motorbike is visible because other teams can get the geometry of the bike from one photo… perfect for us! We got a good amount of photos of some racing motorbikes from the side view. Of course there is some distortion because of perspective and camera lens but our result was convincing. Speaking about dimensions, this motorbike was supposed to be between Moto3 and Moto2 (as we saw later, it should be more like moto3), so here are the results:

Different side-view photos aligned and extracted geometries

Different side-view photos aligned and extracted geometries

In red, Moto3 geometries, in blue, Moto2 geometries.

In red, Moto3 geometries, in blue, Moto2 geometries.

With this few examples we can say that we have something clear. Red sketches are from Moto3 bikes and blue are from Moto2 bikes. The conclusion we can draw is:

- As expected, Moto2 has longer wheelbase distance, making it more stable on high speeds.

- Moto3 bikes have a smaller rake angle and Moto2 a bigger one. With a smaller rake angle the motorbike should be more maneuverable but more unstable at high speeds. This has some sense as Moto2 bikes are faster than Moto3.

- Forks are a bit longer in Moto2 and handlebar a bit higher too.

- The rider’s position in Moto2 is a little further back. This could be because the size of the engine, fuel tank, etc, not sure but it’s not the most important thing for us now. Also the footrests are further back, but it’s also a rider’s choose.

With this information, we have a clear starting point for geometry.

COG & Anti-squat

TO-DO

Clamps

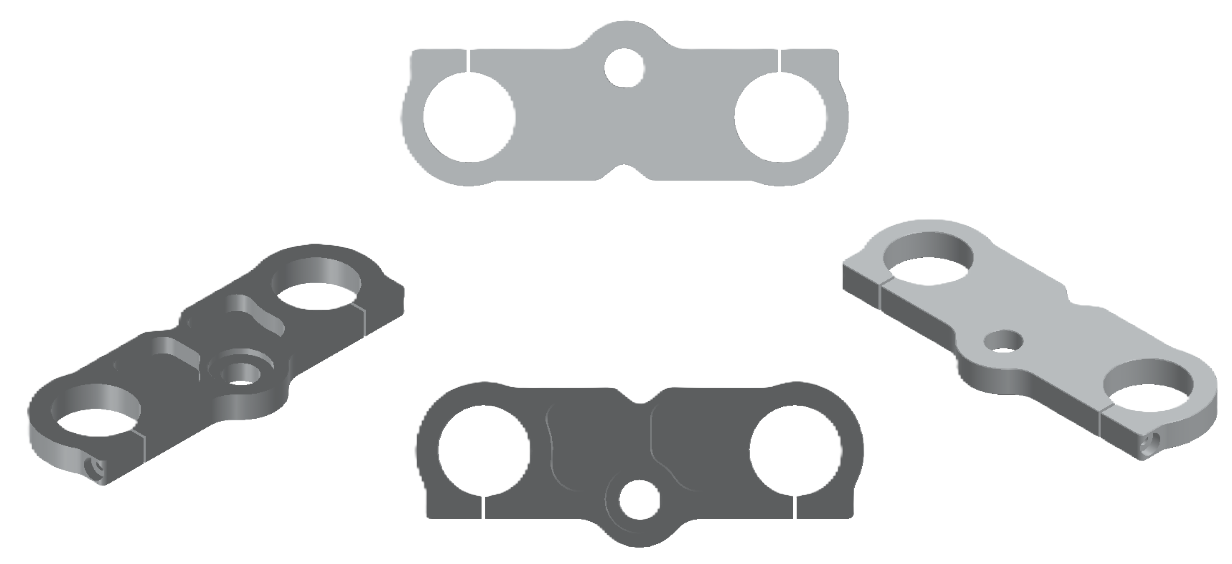

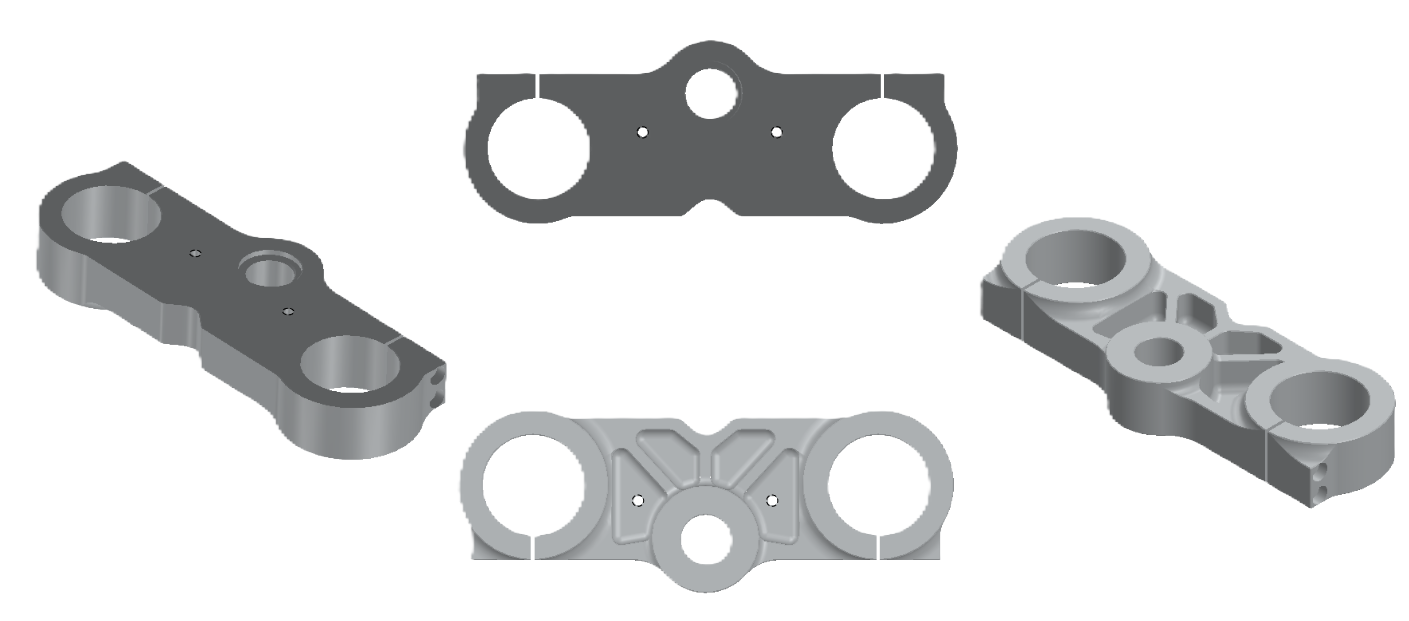

As I mentioned earlier, due to the design of the front axle, it is not possible to use the original yokes of the bike to which the forks belonged to. Therefore it is necessary to design and manufacture custom ones for the prototype.

The only important measurement to focus on is the offset, that is, the distance between the suspension bars and the steering axis as we saw earlier.

Unfortunately we didn’t have time to work on optimizing these parts. I know that they are oversized and their weight could be reduced considerably.

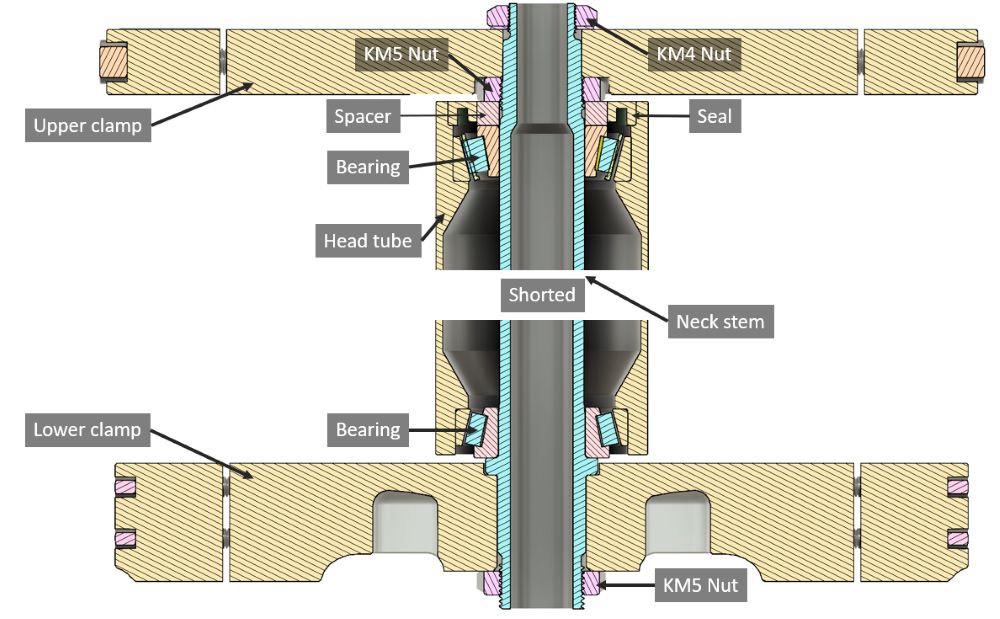

Steering axis

For the design of the steering axle we opted for a well-known and robust structure. The only possible disadvantage of this system is that it is not possible to modify the geometry once the prototype is assembled, but as we mentioned before, it is not something we are going to need so we opted to make it as simple as possible.

Example of an adjustable steering assembly. As you can see in the image, there are some interchangeable pieces. With this parts, the geometry of the steering can be changed without big modifications on the chassis or the clamps.

Example of an adjustable steering assembly. As you can see in the image, there are some interchangeable pieces. With this parts, the geometry of the steering can be changed without big modifications on the chassis or the clamps.

Our design didn’t have this interchangeable parts, but the rest was similar.

Starting from bottom, we can see that we have a steel pipe in the middle (blue one). This pipe is tightened up to the lower clamp with a KM5 nut, so this two pieces are fixed between them.

Then we can find a conical bearing. The inner ring is fixed to the blue pipe and the outer ring is fixed to the steering pipe of the chassis. For this design, we used a inch SKF L44643 bearing on the bottom, with an inner diameter of 1 inch (25.4 mm). This means that the neck stem has a smaller diameter on the top so we can mount the lower bearing without problem.

On the top we have the other bearing, this time we have a SKF 30205 with an inner diameter of 25 mm. To cover this bearing we have a seal with a spacer inside to supply the difference of diameter and to allow a tolerance for the thread manufacturing.

All this is packed with a KM5 nut. This nut is important as it is the adjustment nut for the steering. We need to tighten it just right so that the conical bearings are not loose but at the same time not too hard.

Behind this is the upper yoke. This yoke is held in place with a KM4 nut and a small 1mm washer that acts as a spacer. Also this tights the lower KM5 nut, preventing it from loosing.

With the steering axle design finished, we already have the front point of the chassis and all the geometries defined so we can start with the design of it.

Chassis

I’m not going to extend too much this section. There are a lot of posts on internet speaking about chassis types, materials etc. For this prototype we could use 3 type of chassis:

- Beam (aluminum): It’s a good option but It’s expensive for our resources so we discard this one.

- Beam (carbon fiber): Another good option but It’s expensive, we don’t have the resources (machinery and companies that could help us with it) and also we don’t have the knowledge and experience. It’s probably the most complex one for design and manufacture.

- Beam (steel): The team of a previous edition made one with sheet metal. In my opinion, it takes too much volume for this prototype, but it could be a cheap and easy option.

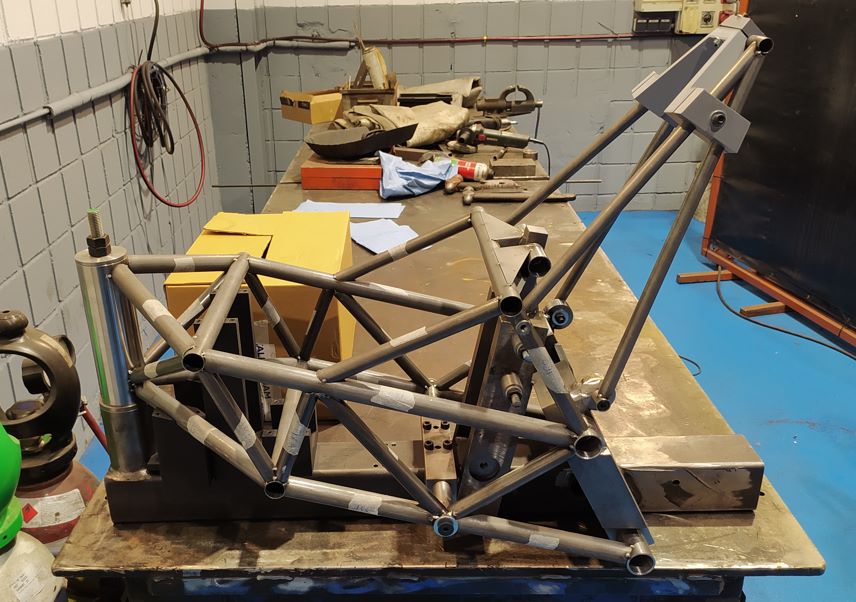

- Tubular (steel): It’s the perfect option for us. It’s cheap, easy to design, calculate and manufacture.

The material selected will be chrome molybdenum (42CrMo4). We will manufacture a tubular chassis with pipes of 16, 20 and 25mm of outer diameter and 1mm wall thickness. It is a cheap material, easy to weld and one of our sponsors had it in stock.

Design

The next step is to put the restrictions on the 3D CAD software. We have some mandatory restrictions such as maximum length, minimum distance between floor and fairing, etc. Also our restrictions, such as both wheels must be aligned on the same plane and tangent to the floor.

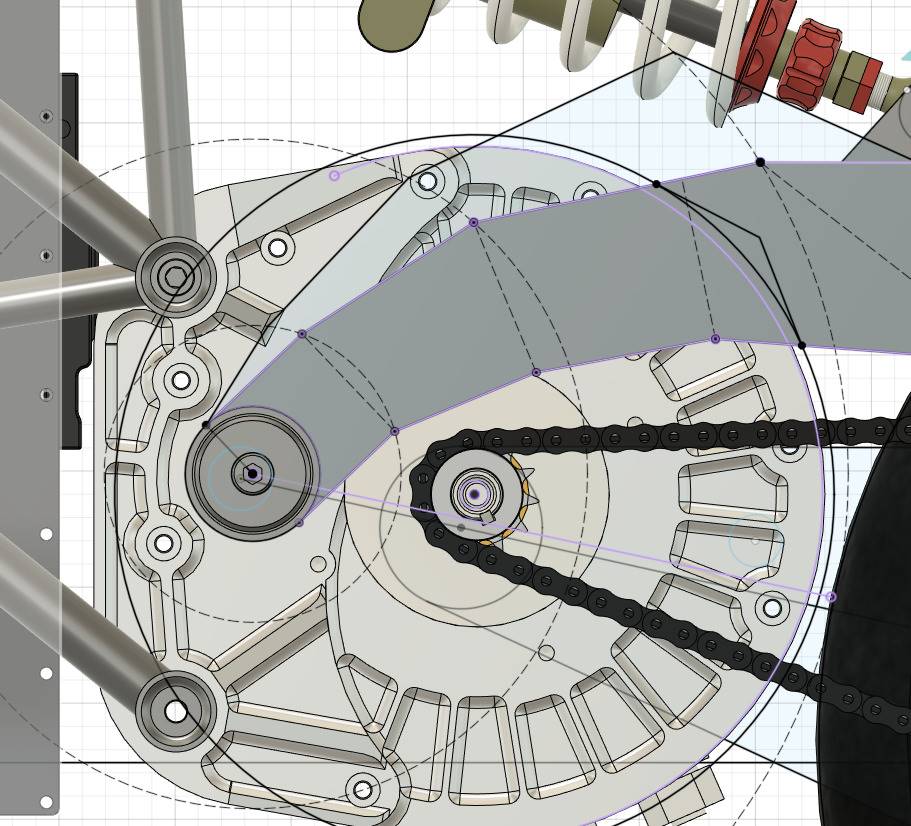

The next step is to place the electric motor. We still don’t know the position it will have in the prototype but we can start by aligning it with the central plane of the wheels. The order of proceeding would be, once we have the front wheel placed, we need to place the rear wheel aligned with the front. From here, the next restriction that applies to us is that the chain must be parallel to the central plane of the bike. Also, the end of the motor shaft (where the sprocket is placed) and the crown (rear wheel) must be aligned.

From this point we would have to start with the design of the battery since it is the part that will take up the most space and that will condition the rest of the design. During the process, that was the natural cycle although I will talk about the battery later. Let’s assume at this point that we have the exterior of the battery container designed.

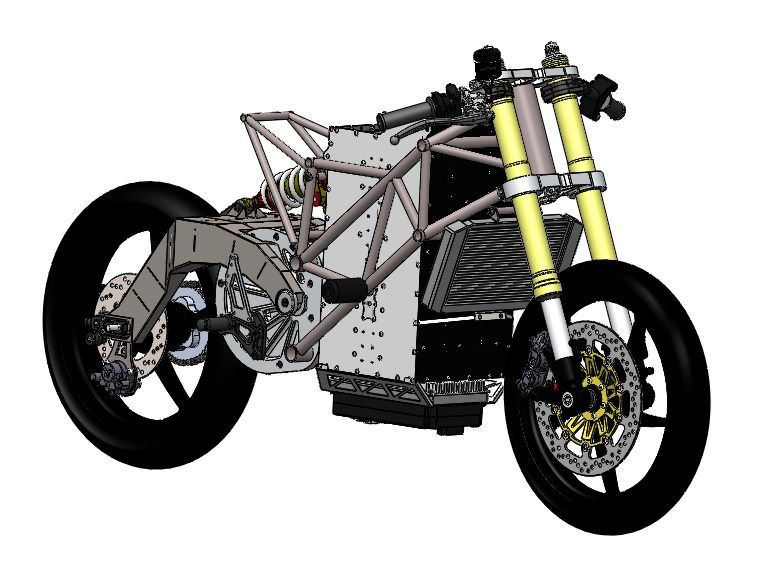

As I mentioned before, we will try to use a layout in which the battery is vertical in the prototype and as low as possible, delaying the position of the motor as close to the rear wheel as possible. On the other hand, the idea is to take advantage of the rigidity that an element like the motor gives us to use it as a chassis.

We don’t want to have more weight on one side than the other of the prototype. This means that the battery pack must be centered and aligned with the central plane of the wheels (and the motorbike). The next ideal situation would be to center the motor with the central plane of the bike.

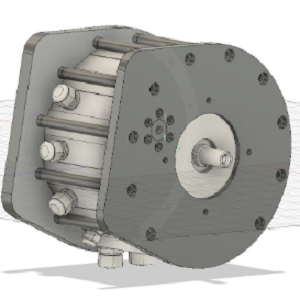

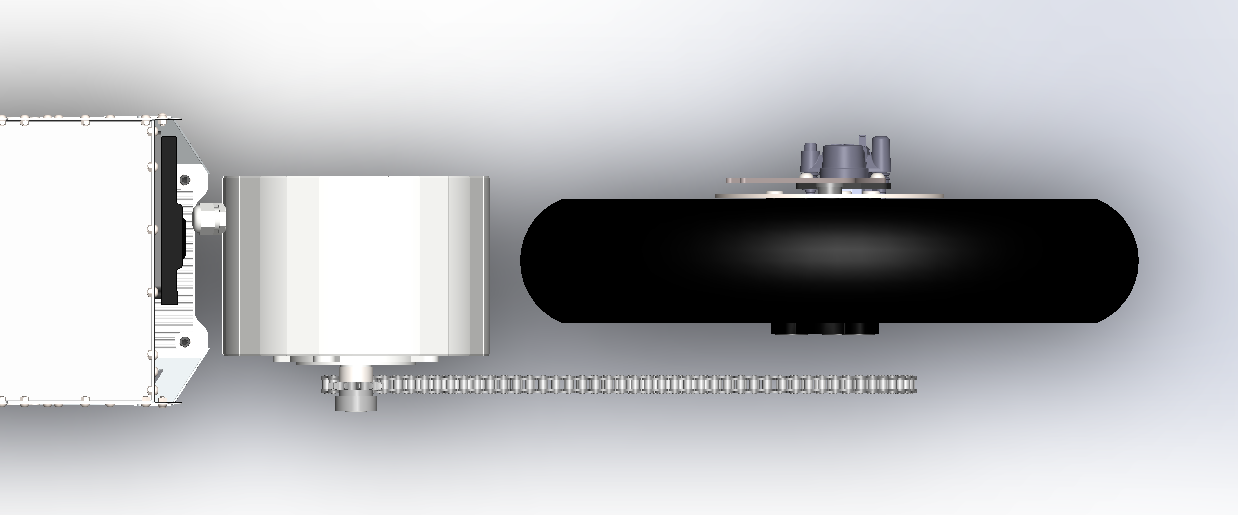

Battery and motor centered in the central plane of the motorcycle

Battery and motor centered in the central plane of the motorcycle

In the swingarm section ahead, I discuss motor lateral placement and its limitations. This is the main reason why we will end up mounting the motor offset to one side as shown below.

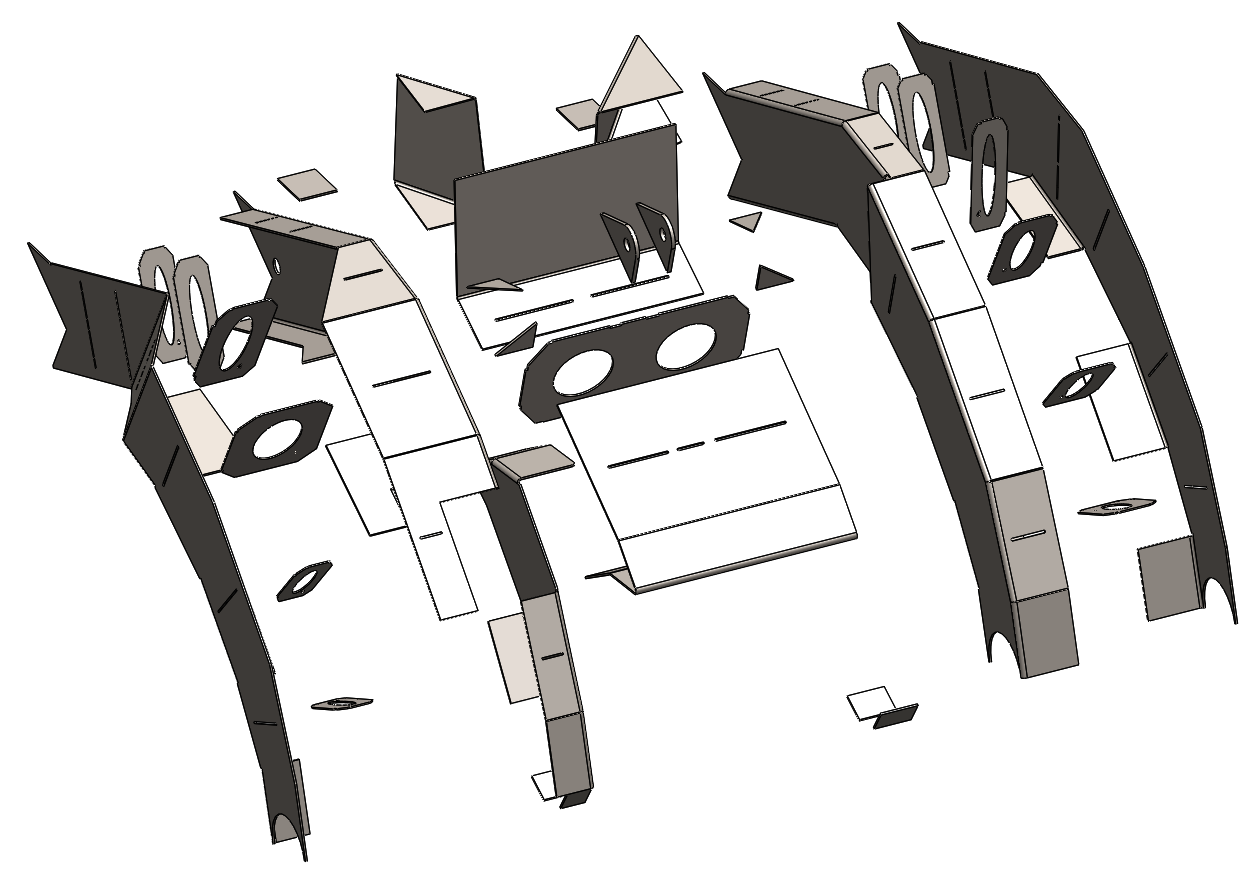

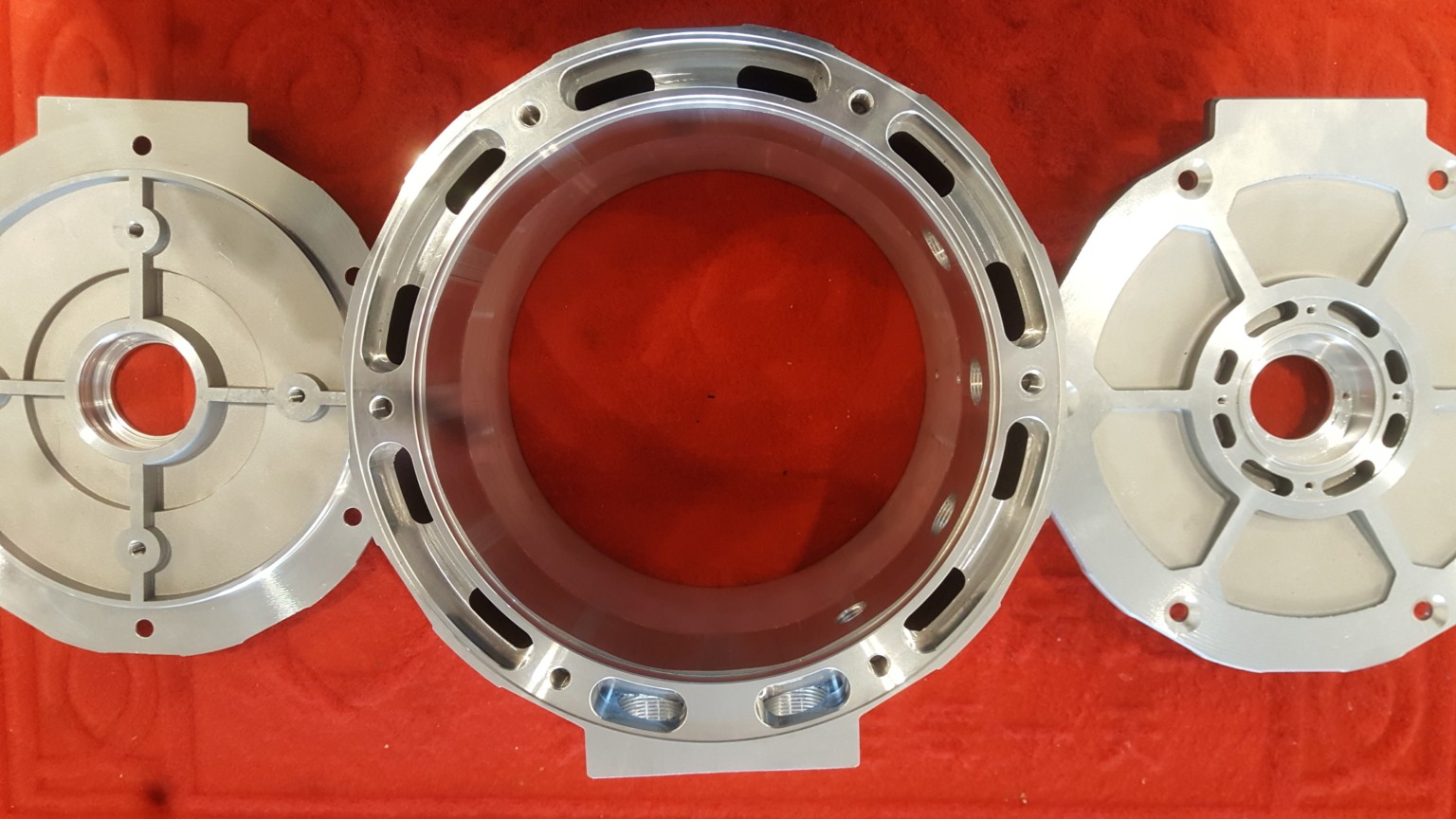

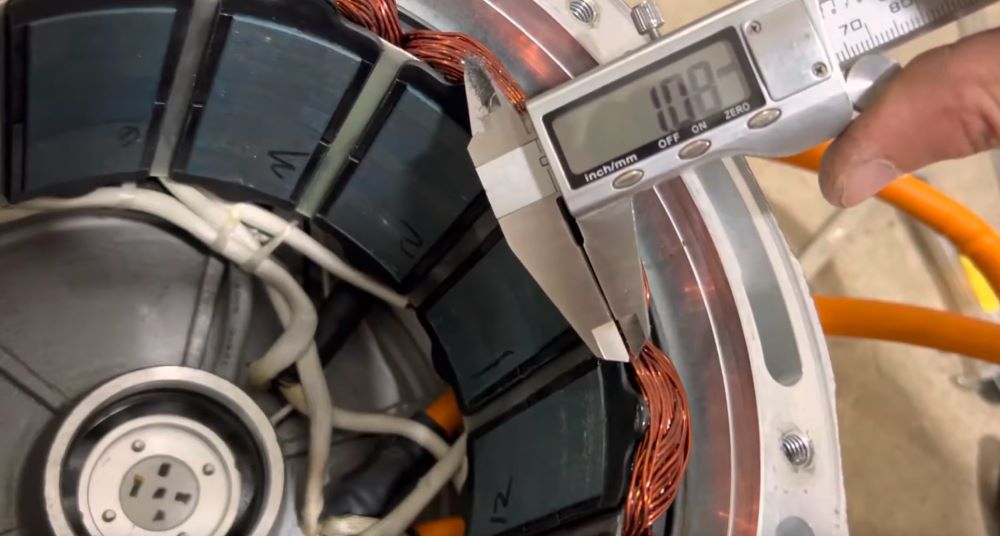

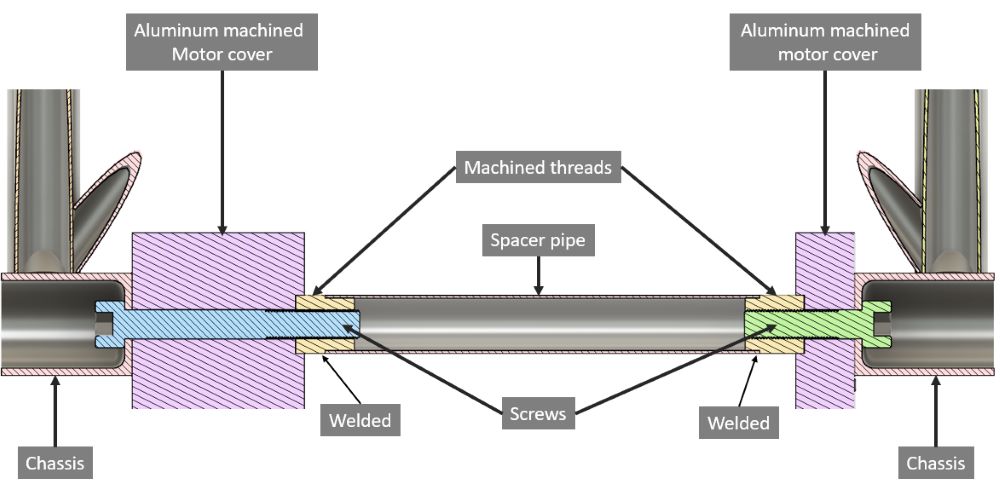

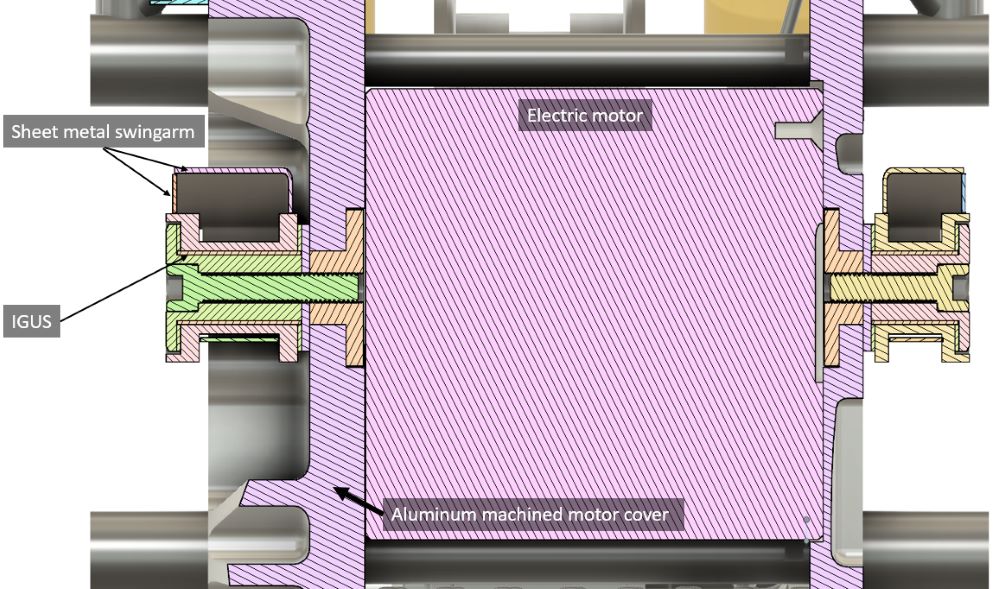

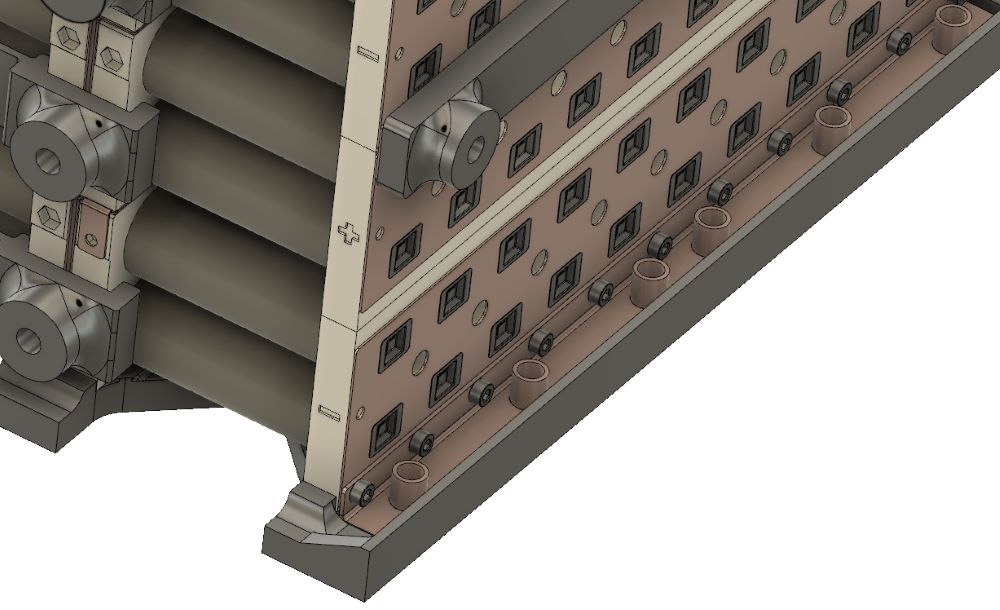

With the electric motor in place it was time to develop the idea of the chassis with the motor embedded. To do this, two side covers were designed that embraced the motor and to which the chassis and swingarm would be attached as previously mentioned.

Final design. Note that the spacers between two sides are made with a pipe instead of a bar to reduce the final weight. They have a welded bushes on both sides with the threads.

Final design. Note that the spacers between two sides are made with a pipe instead of a bar to reduce the final weight. They have a welded bushes on both sides with the threads.

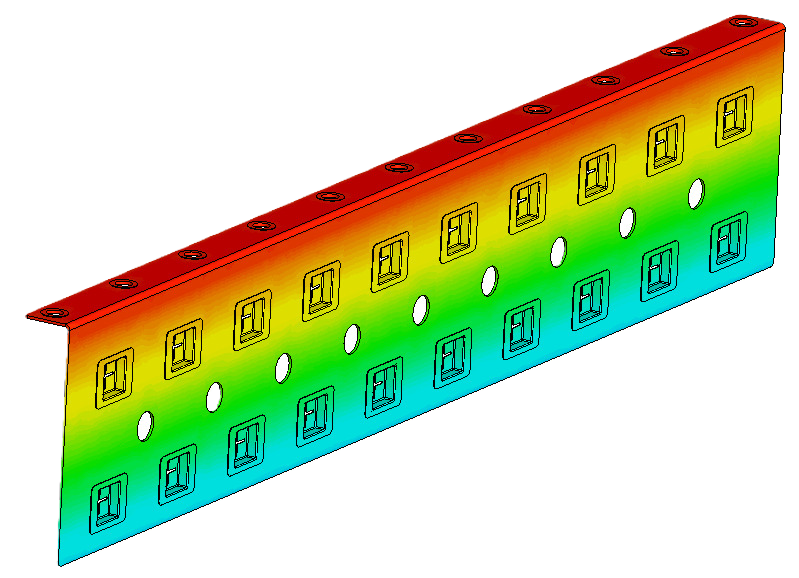

Analyzing the design in more detail later, I realized that there is a lot of material left over in the rear area since the point of maximum load of these two pieces of aluminum is between the screws that connect to the chassis and the anchor points of the swingarm, but when you do not have previous experience in this type of design you always tend to secure and put more material.

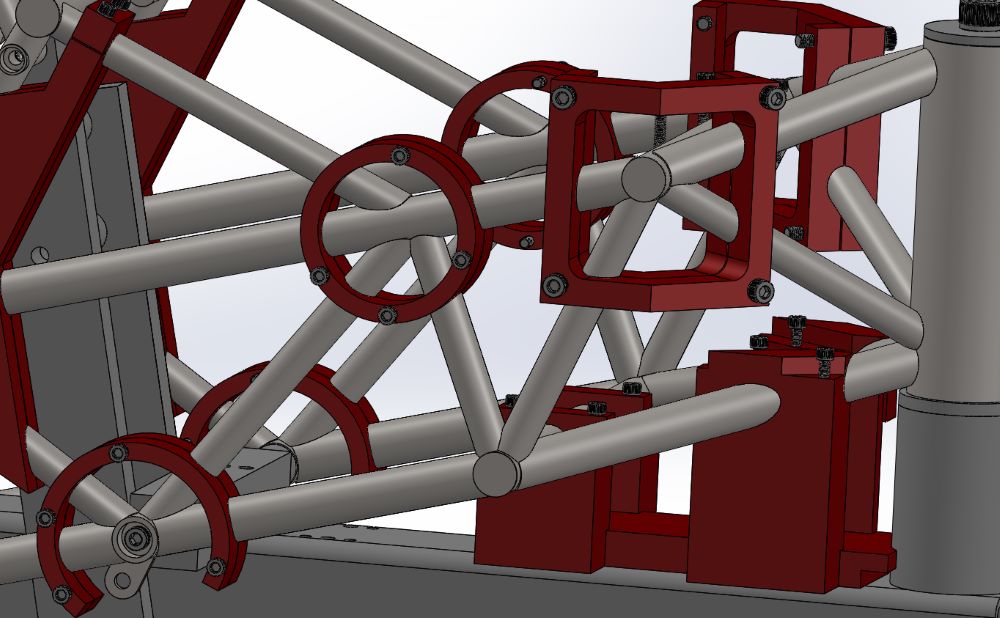

With these motor covers designed, it was time to start with the chassis itself. To do this I started with a 3D sketch restricting the measurements we needed. One of the restrictions we tried to do was not to use bent tubes, both because of their loss of rigidity (straight tubes are better) and the complexity that would be involved in manufacturing them.

After extruding the pipes and cutting them, we are left with the following design.

It is well known that this is not the best way to technically design a chassis, but our time limit prevented us from working further on finite element analysis, structural optimization, etc. On the other hand, referring to what was mentioned above, we don’t have the knowledge or the resources to analyze a chassis behavior and how it works in a real environment so I didn’t want to waste too much time on it. Also, the problem is not to give more or less lateral deflection, or stiffness in X points. The problem is how can we know how much deflection you want to have. We don’t have the capacity and knowledge to get and analyze that data.

Some chassis design details

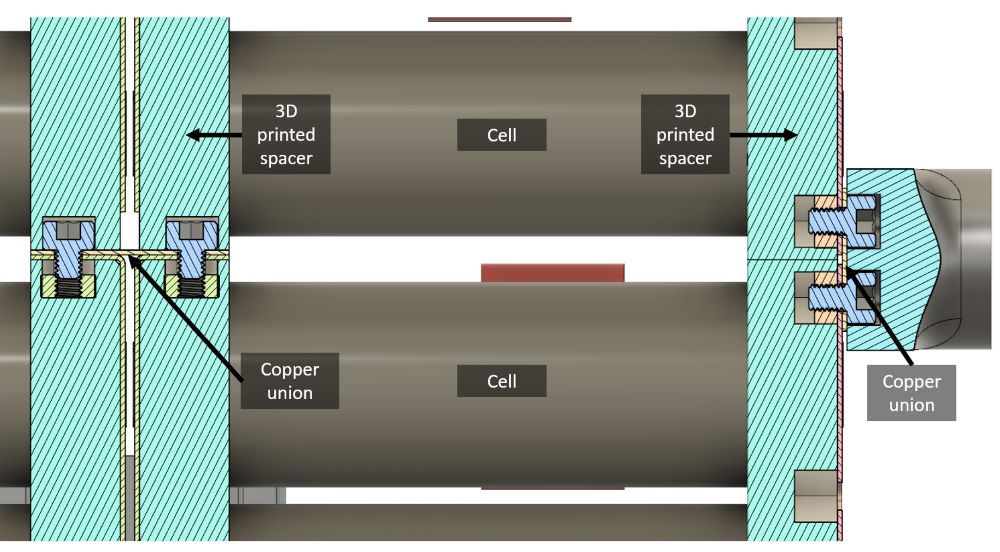

Here you can view a sectional view of the unions between the chassis and the aluminum-machined parts covering the electric motor.

Detailed view of the join between chassis and motor cases

Detailed view of the join between chassis and motor cases

For the union between the machined aluminum parts, we manufactured 2 bushings with an internal thread. This parts were welded to a 16 mm diameter tube with 1 mm wall, making the design lighter than with a big screw for example.

Chassis jig

Once the chassis was designed, it was time to design the welding jig. This is a structure to keep the position of the important points of the chassis during welding. This is because welding reaches high temperatures that cause the steel to twist and move from the original position. With the chassis jig we ensure that these points do not move during welding process.

We had a jig from previous editions so we tried to reuse it by manufacturing some new parts and machining different sections.

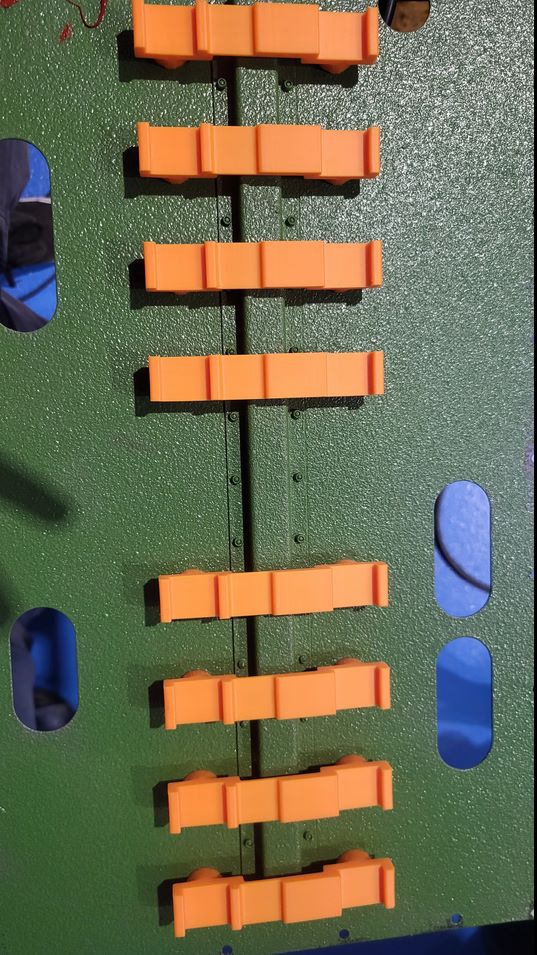

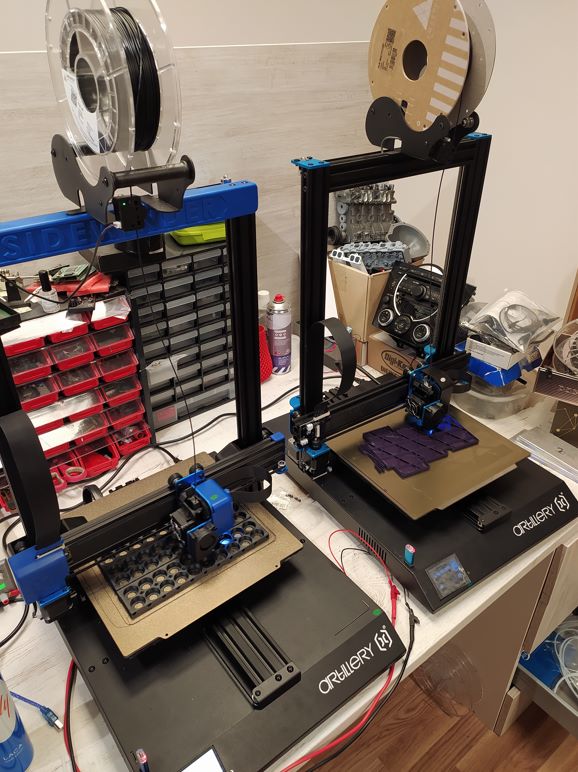

A new feature implemented for the manufacture of the chassis was the use of 3D printed supports to hold the pipes during welding. The purpose of these supports was not to have great resistance. We wanted simply to hold the pipes in their position during the initial phases of welding pointing, as well as to avoid having to hold them by hand and to be able to preview the reshaping before welding.

3D printed supports for chassis manufacturing

3D printed supports for chassis manufacturing

Pre-assembly of the chassis. 3D printed supports in order to position the pipes before welding the chassis.

Pre-assembly of the chassis. 3D printed supports in order to position the pipes before welding the chassis.

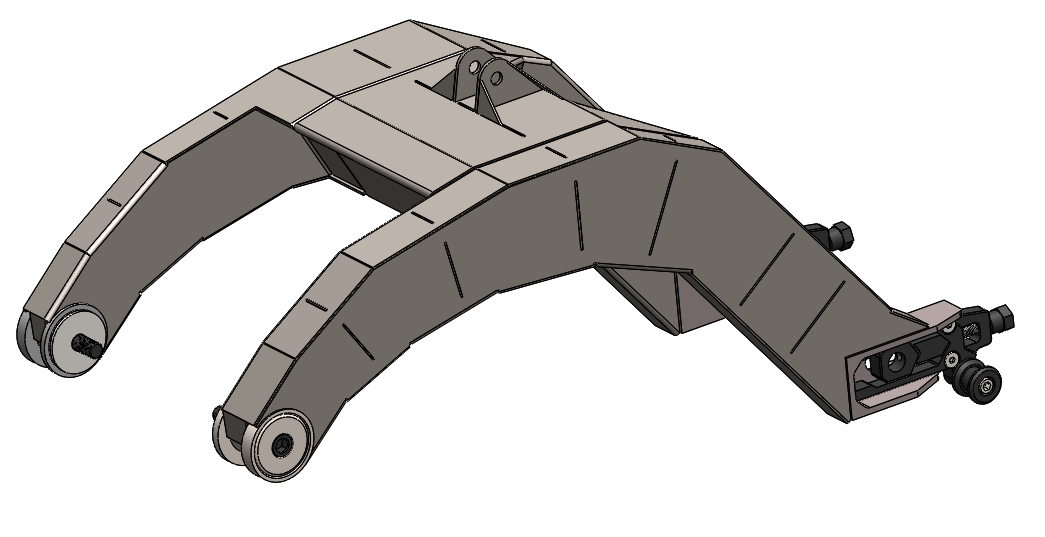

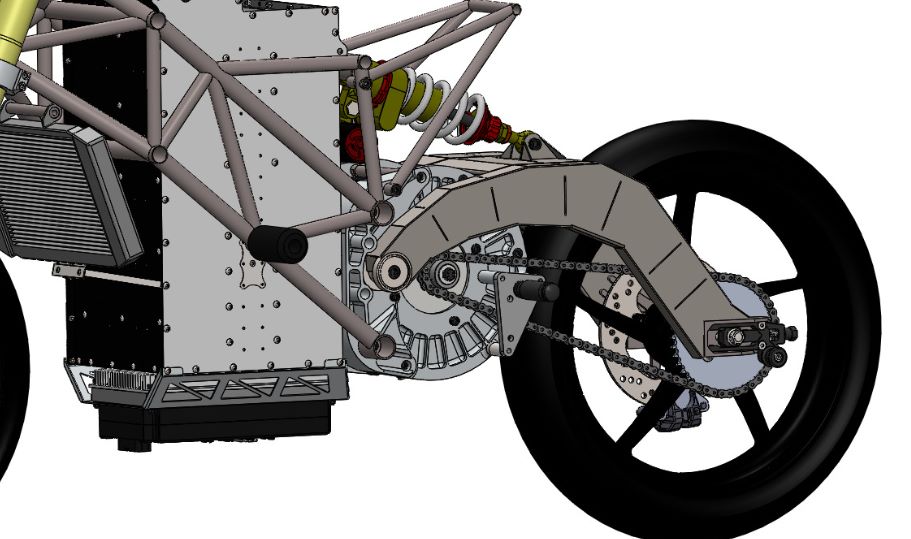

Swingarm

The swingarm was designed at the same time as the chassis since one influences the other in certain decisions such as the position of the rear shock absorber or the swingarm axis.

Introduction

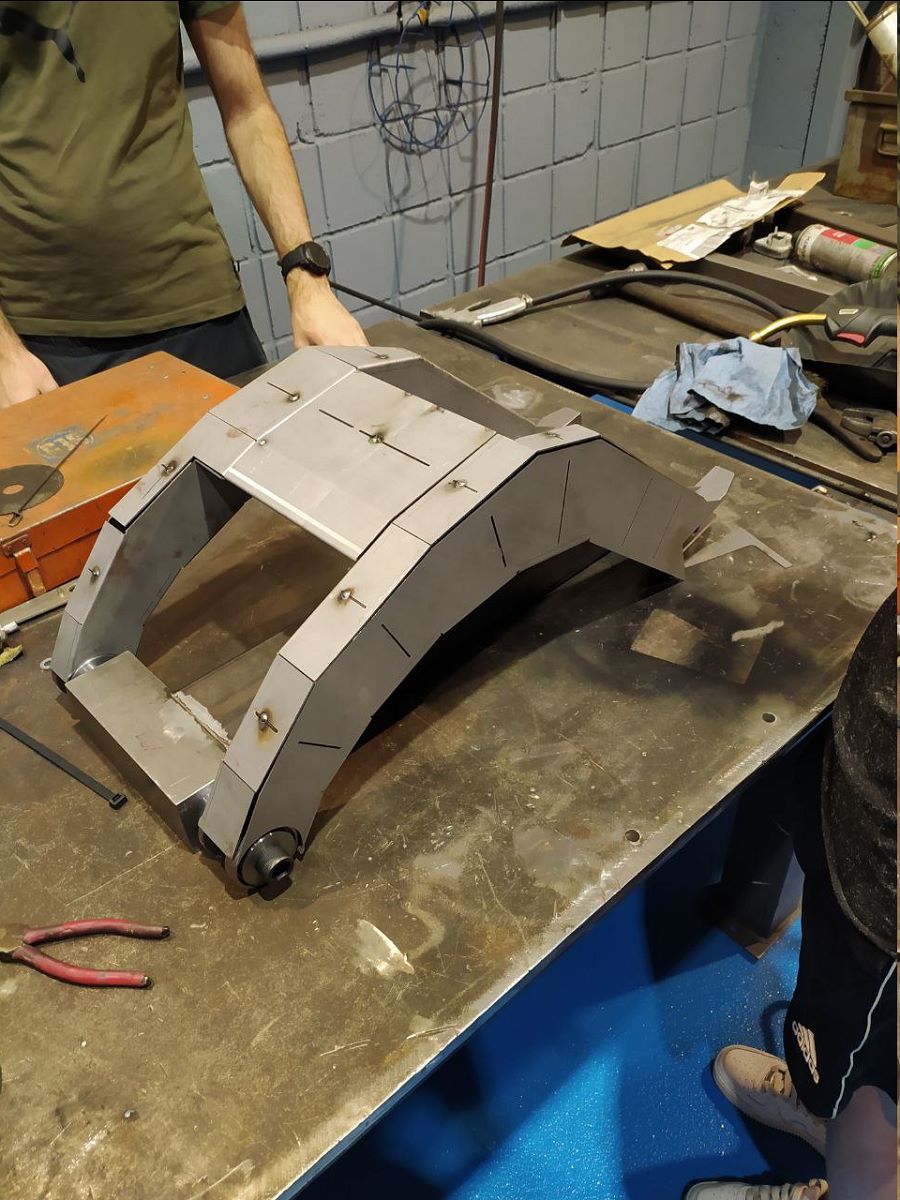

As I mentioned before, the initial idea was to manufacture the swing arm with folded sheet metal. This has many advantages, although the only drawback I see is space. It is a hollow structure with low weight but has a larger volume.

The first thing was to define the geometry it would have. After several options, we decided to make a banana-type swingarm.

With this type of swingarm we would have sufficient length and rigidity, since the other option was to make a traditional swingarm but we would not have space to place the shock absorber apart from being a very short swingarm. In addition, this design would allow us to bring the wheel closer to the electric motor, allowing us to shorten the wheelbase of the bike as much as possible.

To do this, I searched for information about the rear wheel travel that motorcycles usually have. It was around 130 mm6.

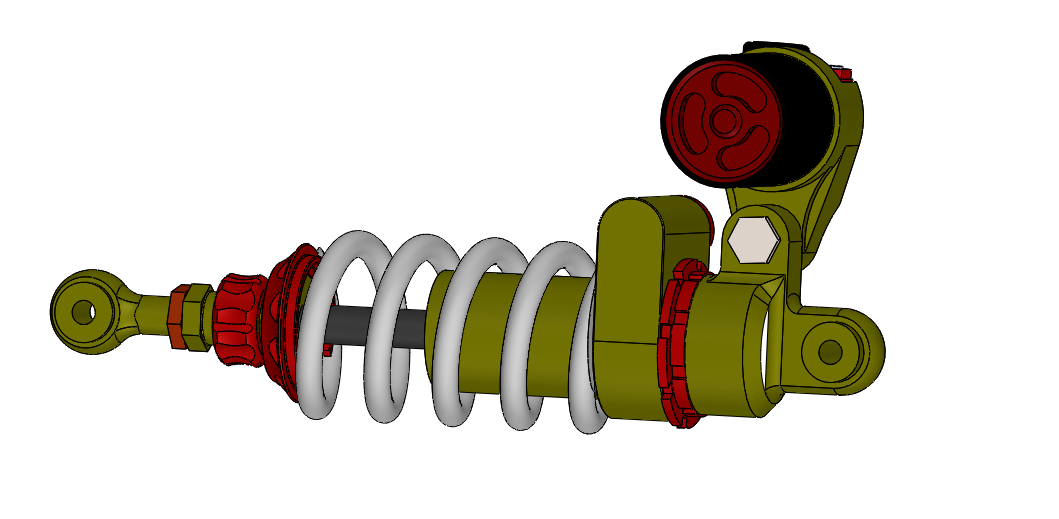

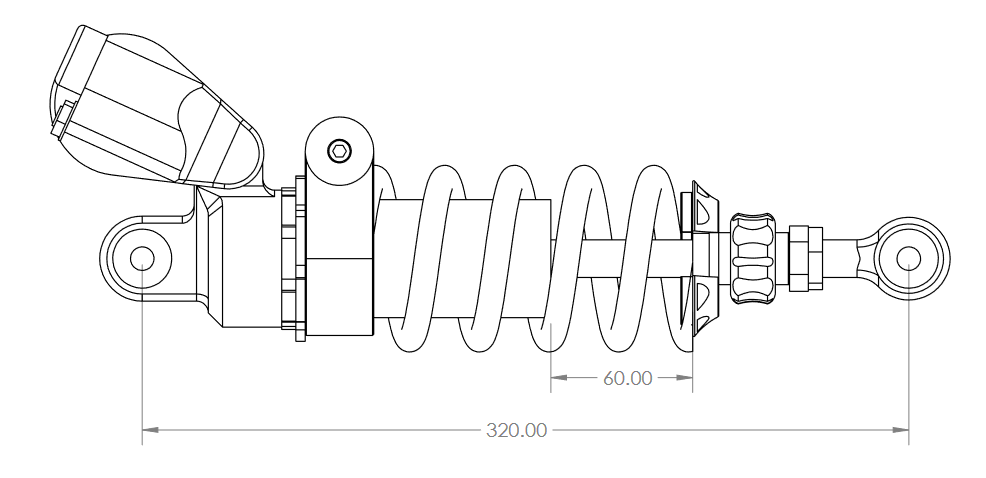

The first thing was to select a shock absorber to know its data such as extended length, compressed length and travel. For price and features we bought a second-hand MUPO GT2.

Rear shock

TO-DO: Rear shock geometry and spring calculations.

Total length and travel distance

Total length and travel distance

With this shock absorber we had a travel distance of 60 mm. This would be one of the restrictions to be applied to the design. The other restriction would be the maximum travel of the rear wheel that was around 130 mm. Of course, there is nothing scientific about this “assumption” but we have to remember that there wasn’t too much time remaining to finish the project.

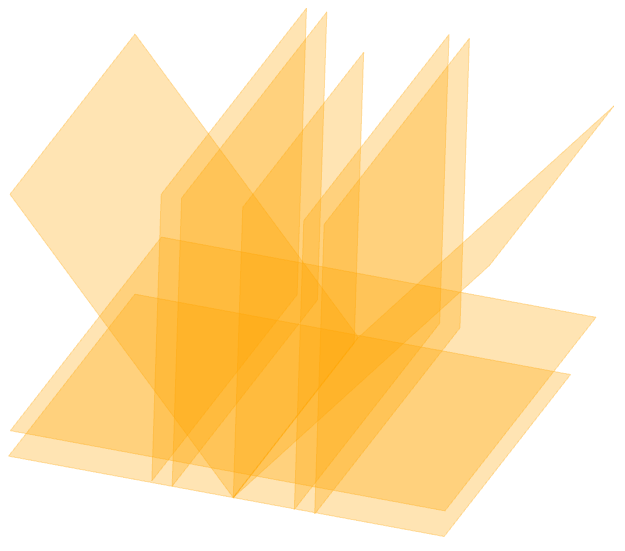

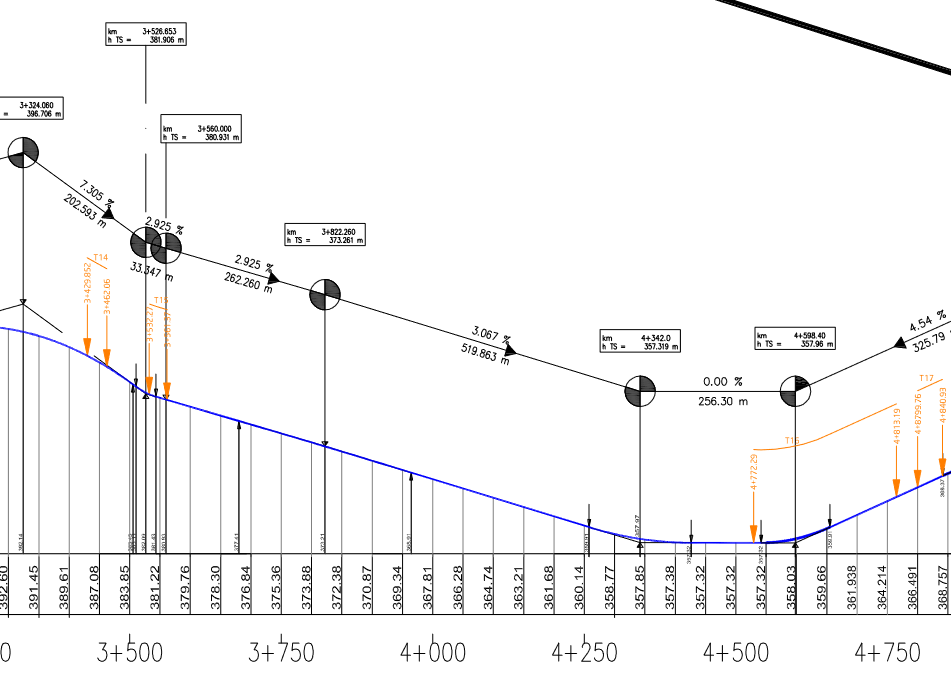

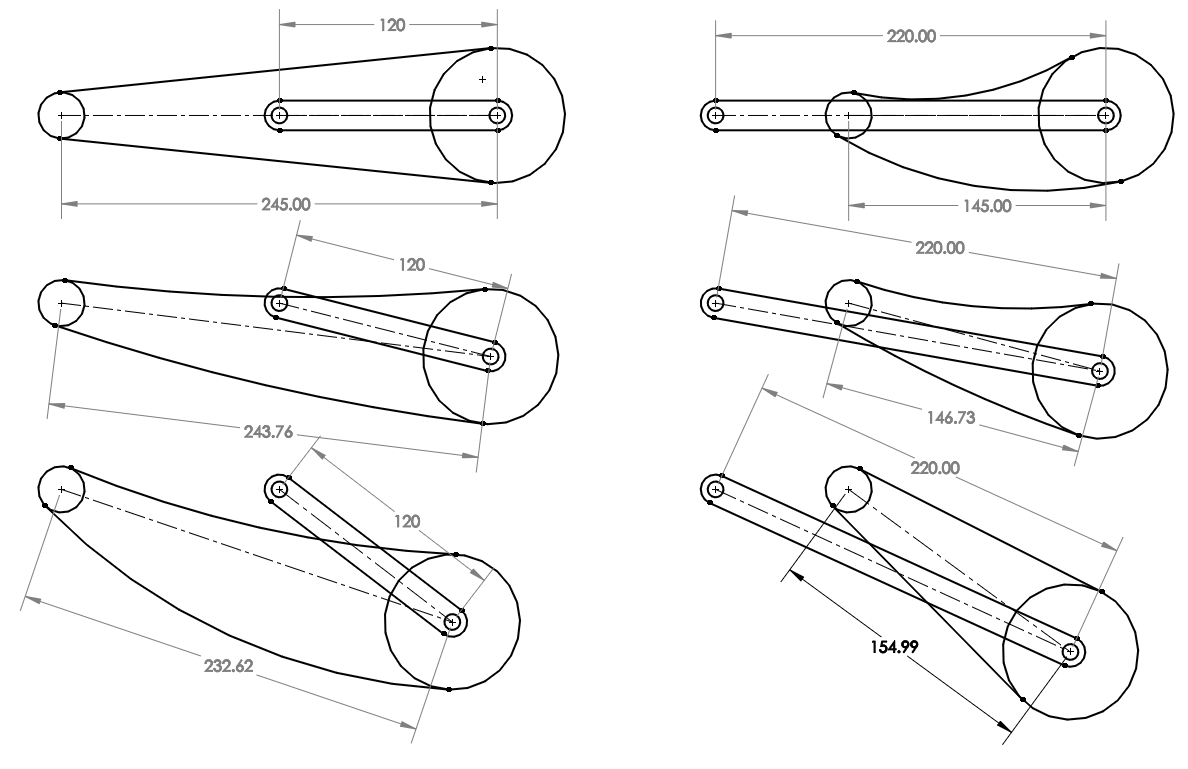

Swingarm geometry

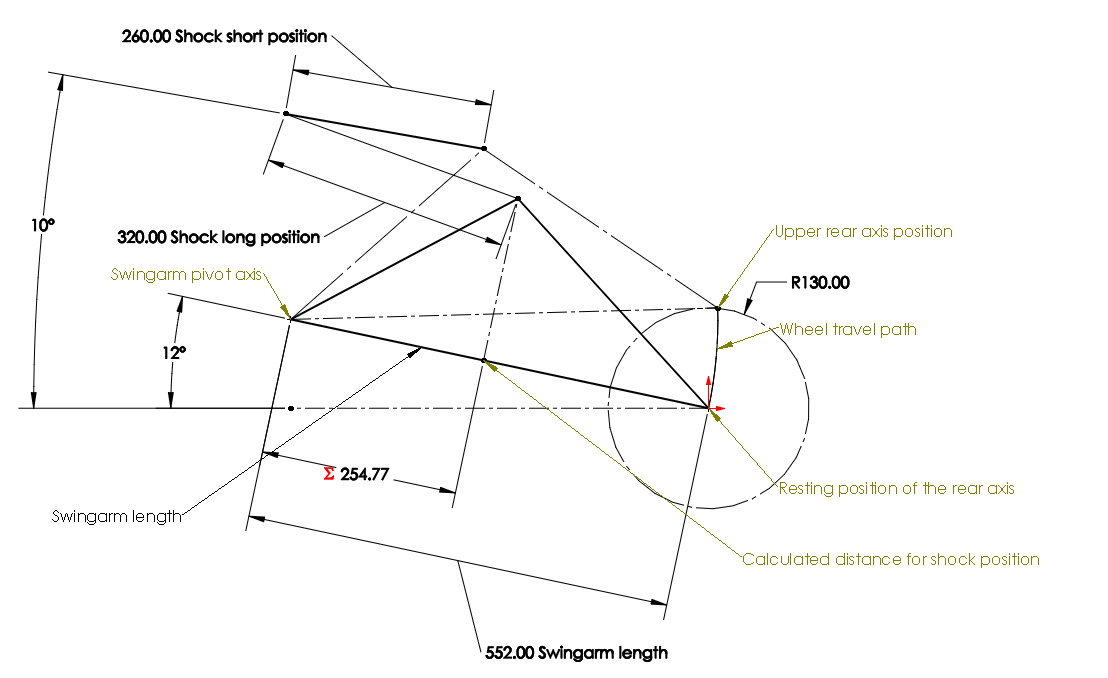

For this purpose, we prepared a sketch with the maximum and minimum positions that the geometry would have to comply with:

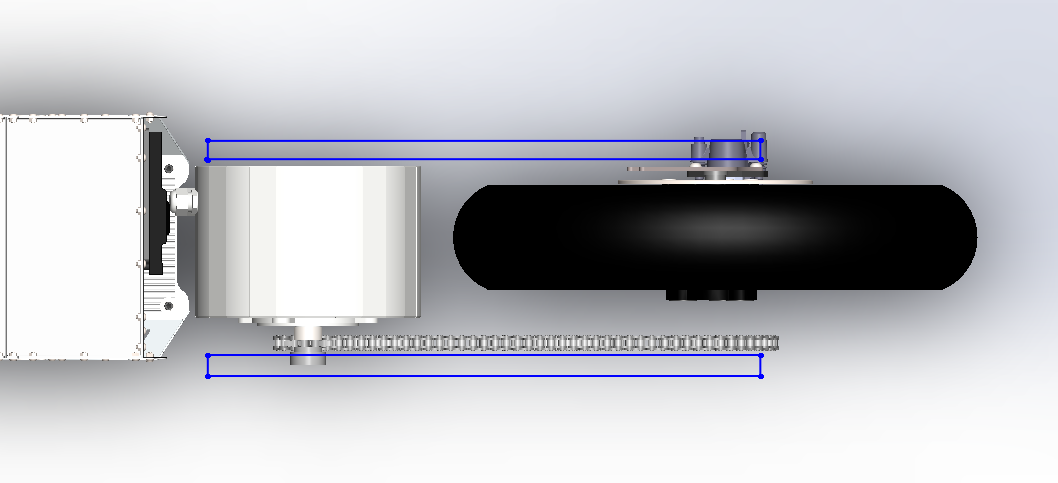

Some defined values are the 12º between the ground parallel and the tilt of the swingarm. This is given by the geometry obtained from the photographs. The 10º between the ground and the shock absorber in the most retracted position is to restrict the sketch in a position that was valid for our design. The distance between the output motor shaft and the swingarm pivot axis (97 mm) is calculated by the largest sprocket we expected to mount (14 teeth) and trying to keep both points as close as possible.

Finally, the position in which we must place the shock absorber on the swingarm is given by the length that the shock absorber travels in the compression process (60mm) and the length that the rear wheel should travel during that journey (130 mm). With this calculation we get the distance of 254.77 mm.

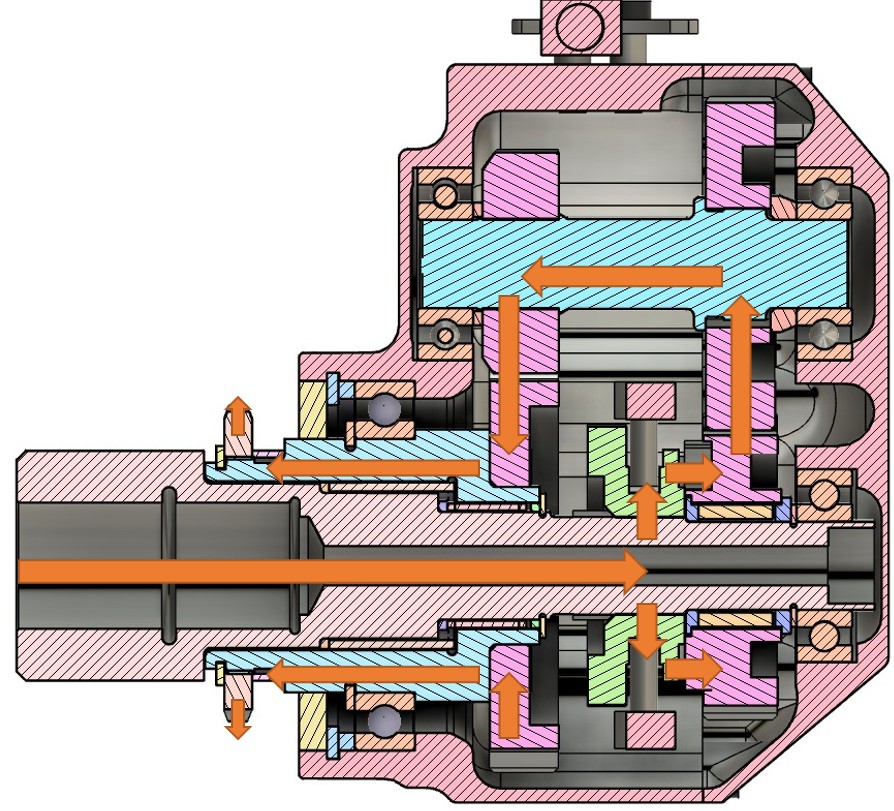

Chain geometry

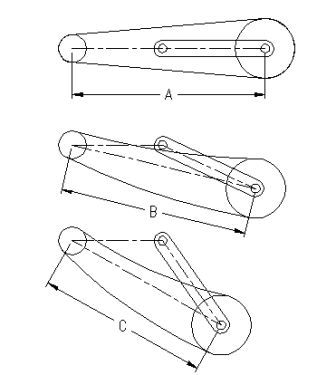

The next step is to calculate the position of the motor sprocket for chain elongation. Due to lack of time we could not accurately calculate the anti-squat so we took the decision to align the motor sprocket with the center position of the swingarm. As mentioned above, the idea is to mount the electric motor as near to the rear wheel as possible. This means that we will have an inverted situation respect to the electric motor pinion and swingarm. By having the sprocket inverted respect to the pivot point of the swingarm, this system works the opposite of the above mentioned, i.e. when the 3 points are aligned we have a shorter chain and when the motor sprocket is misaligned we have longer distances.

Common swingarm vs inverted swingarm. Note that on the normal one when the pinion, pivot point and rear axis get misaligned, the distance between the pinion and the rear axis is shorted meanwhile on the inverted swingarm it has the reverse effect.

Common swingarm vs inverted swingarm. Note that on the normal one when the pinion, pivot point and rear axis get misaligned, the distance between the pinion and the rear axis is shorted meanwhile on the inverted swingarm it has the reverse effect.

We decided to align the sprocket with the swingarm pivot point and the rear wheel when the suspension is on the 25% of the complete travel (SAG). This will allow us to have the chain with the maximum tension on that point.

The soft blue area reveals the position of the swingarm on the most compressed position.

The soft blue area reveals the position of the swingarm on the most compressed position.

As you can see, the electric motor pinion is a bit up from the line between the swingarm pivot and rear wheel axis. This is the rest position without load.

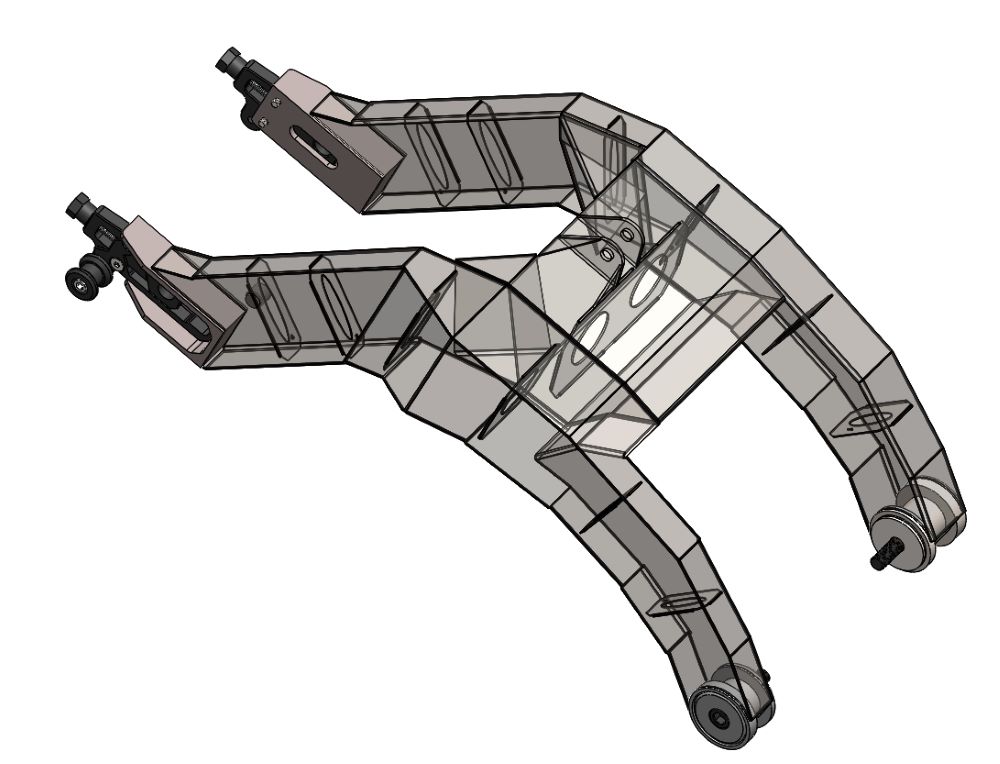

Swingarm design

With this data we already had the main points to start with the design: pivot point, rear wheel axle and rear shock absorber point. The first thing was to start designing it as a solid part. From the side view it was quite simple, taking care that we were going to manufacture it in folded sheet metal.

The biggest challenge was on the top plane. It would not be a symmetrical swingarm because the anchor points to the chassis were not aligned with the anchor points of the rear wheel. Keep in mind that it’s important to keep the rear axle width as short as possible. For achieving it, we couldn’t design a straight swingarm on both sides.

Electric motor and battery centered with the middle plane of the prototype.

Electric motor and battery centered with the middle plane of the prototype.

We can starte centering the motor with the wheels. The main issue of this design is that the chain would be too far from the rear wheel.

Electric motor aligned with center plane of the motorbike. Note the space between the chain and the rear wheel.

Electric motor aligned with center plane of the motorbike. Note the space between the chain and the rear wheel.

Sketch of the approximate position of the swingarm with this arrangement.

Sketch of the approximate position of the swingarm with this arrangement.

On this position, the distance between the rim and the chain is too high. In addition, the left swingarm would be exposed to the outside as well as the rear axle while the right side would have plenty of margin.

The opposite option would be to align the electric motor on the position where the chain should be.

Chain aligned with the original rim sprocket.

Chain aligned with the original rim sprocket.

This configuration is perfect for the chain. The problem is that the electric motor is displaced to one side, unbalancing the weight to one side of the motorbike. In addition, the swingarm would be very exposed in the front area on one side.

Sketch of the swingarm in this arrangement.

Sketch of the swingarm in this arrangement.

Also we need to be careful with this designs because there will be an extra thickness of the aluminum cover parts of the electric motor. This will increase the issues of this designs making the swingarm more outside than expected.

The solution is to find a middle point between two designs. A point where the motor is enough centered to allow us to put the swingarm front arms on both sides without protruding too much, but at the same time with the crown not too spaced from the rim.

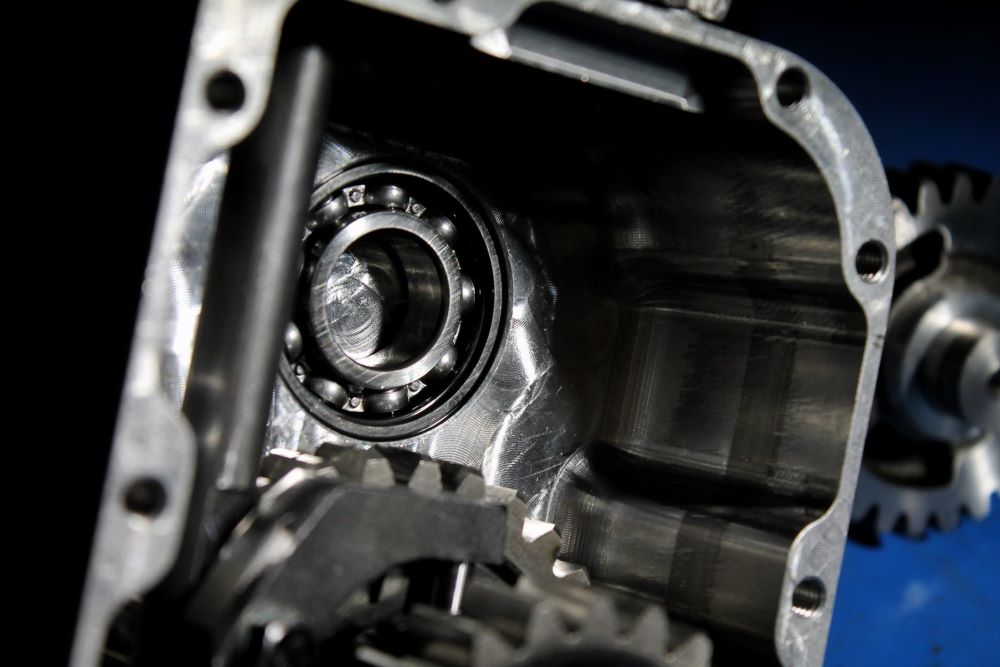

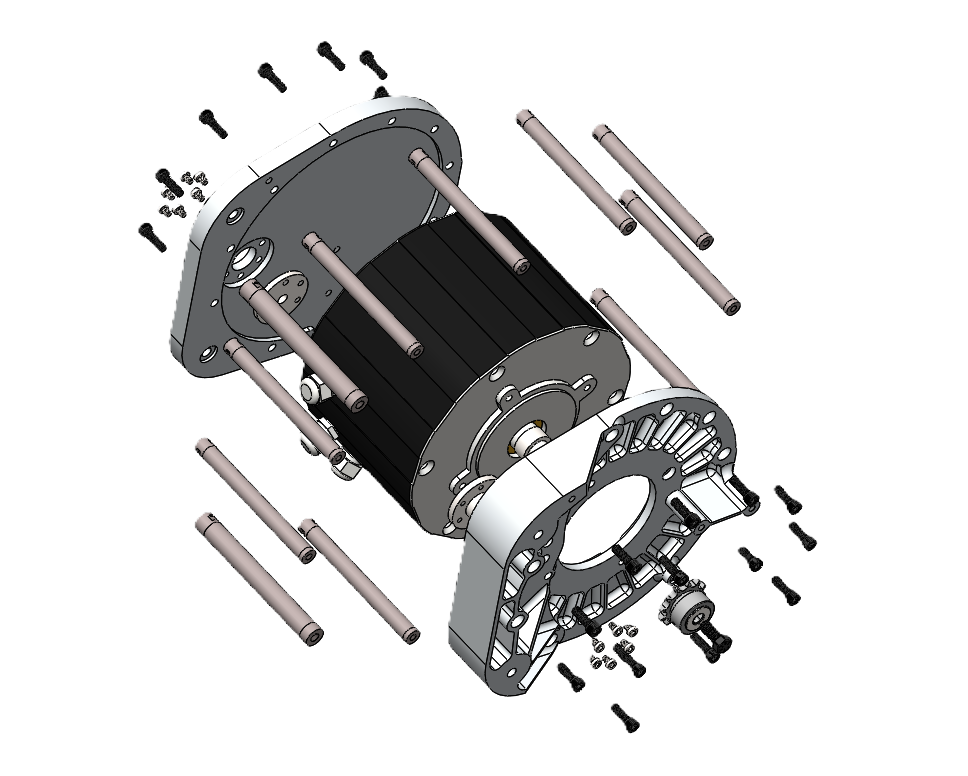

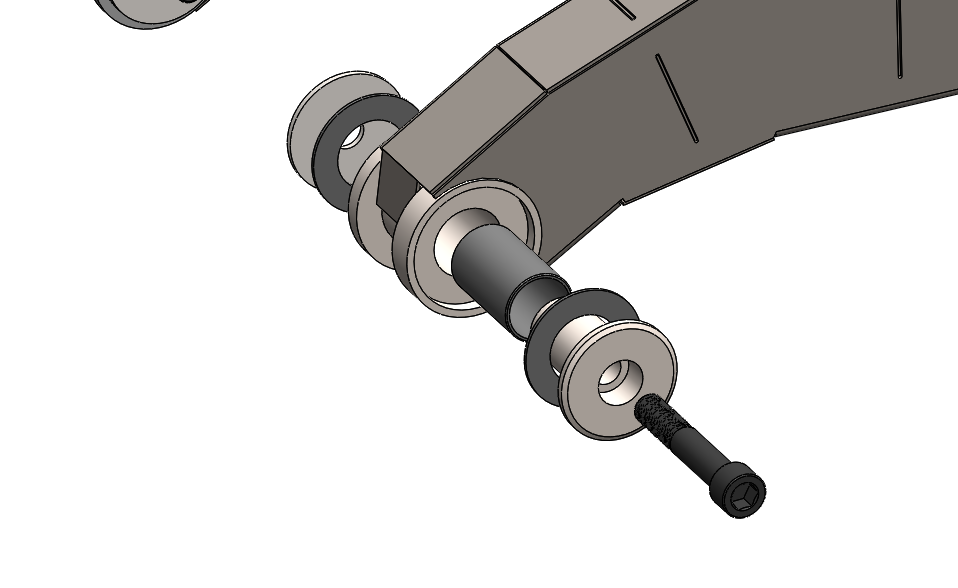

After analyzing different alternatives for the swingarm axle, we decided to use IGUS bushings. This are anti-friction plastic bushings. It’s much simpler system and lighter than using bearings. That’s enough as this prototype is not going to be used too much or on bumpy roads.

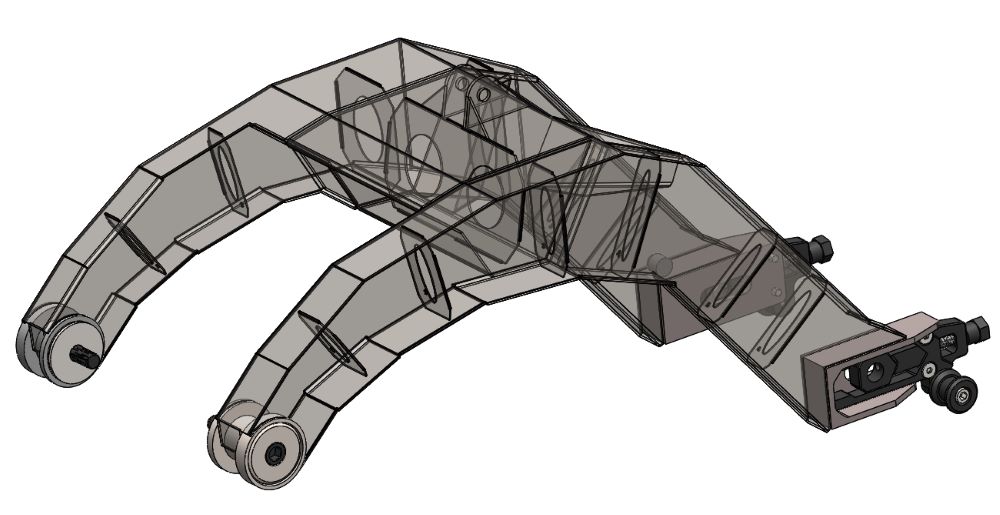

After working on the initial idea, we ended up with the following design:

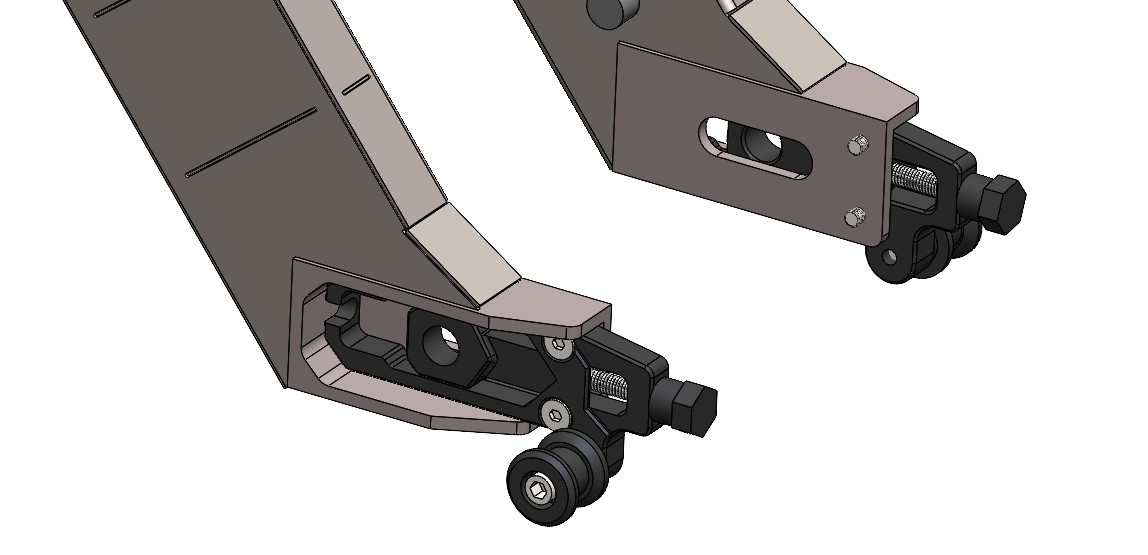

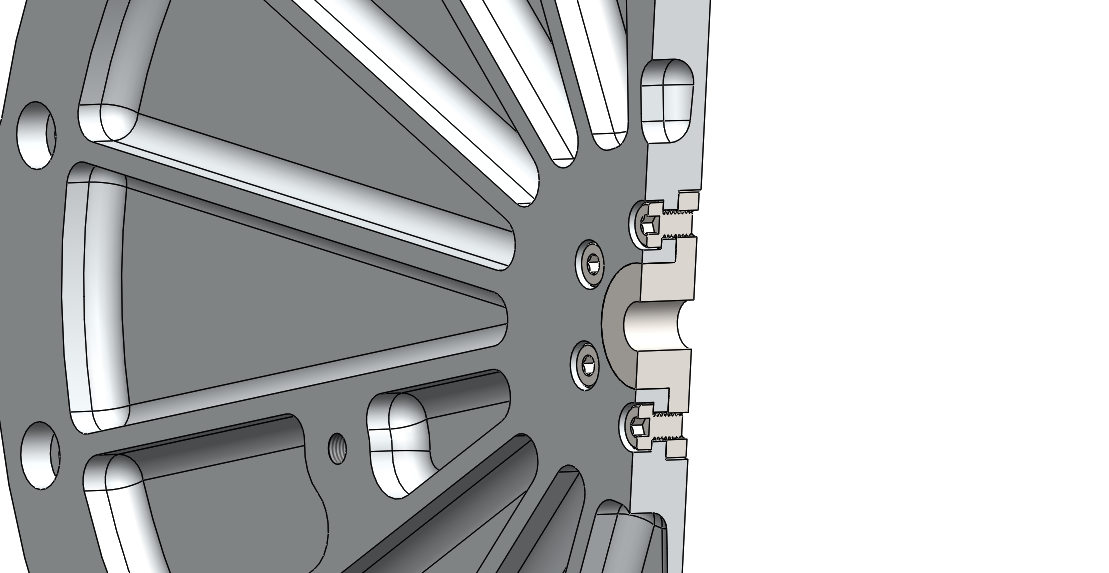

Exploded view of the swingarm pivot

Exploded view of the swingarm pivot

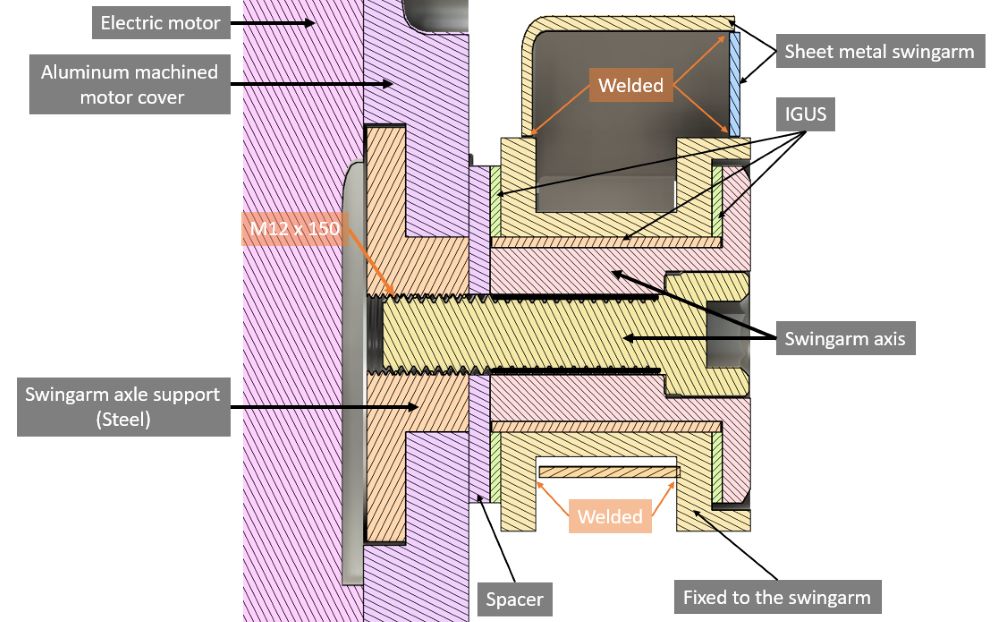

The challenge was there would be no swingarm axle between two sides. We needed to design two aligned anchors to hold the swingarm and pivot on them. The motor covers were going to be manufactured of aluminum and it was not the most suitable material to withstand the forces to which these threads would be subjected, and less on a thread that also had to be fine pitch due to the little space we had to not make this part too wide.

To achieve this, we designed two steel auxiliary parts that would be bolted to the aluminum machined motor cover with a M12x150 (fine pitch) thread. With this, we distribute the load over the machined aluminum parts and ensure a solid thread for the axle.

Section analysis of the swingarm pivot.

Section analysis of the swingarm pivot.

View of the steel inserts on the aluminum electric motor covers.

View of the steel inserts on the aluminum electric motor covers.

Section view of the steel inserts.

Section view of the steel inserts.

Section analysis of the swingarm pivot axis.

Section analysis of the swingarm pivot axis.

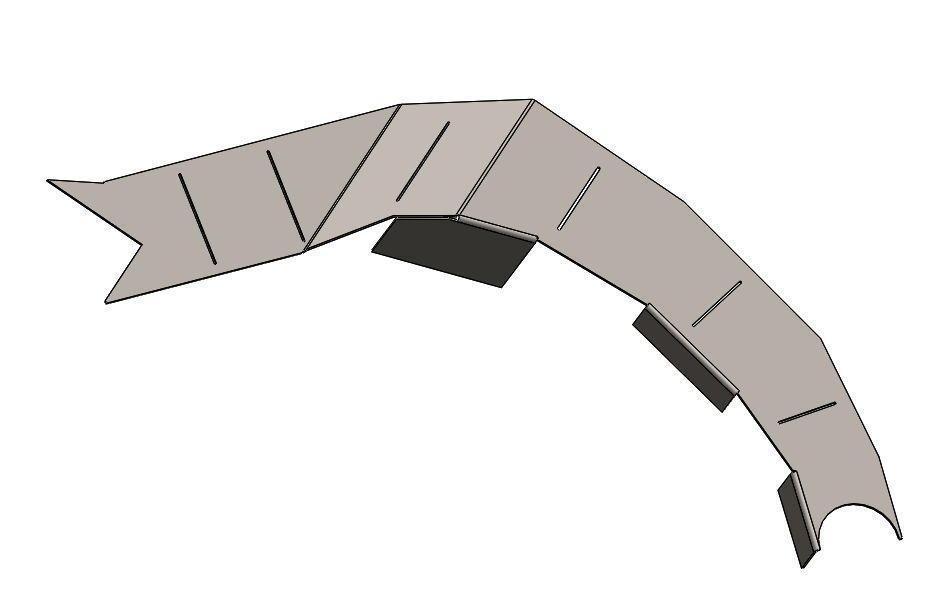

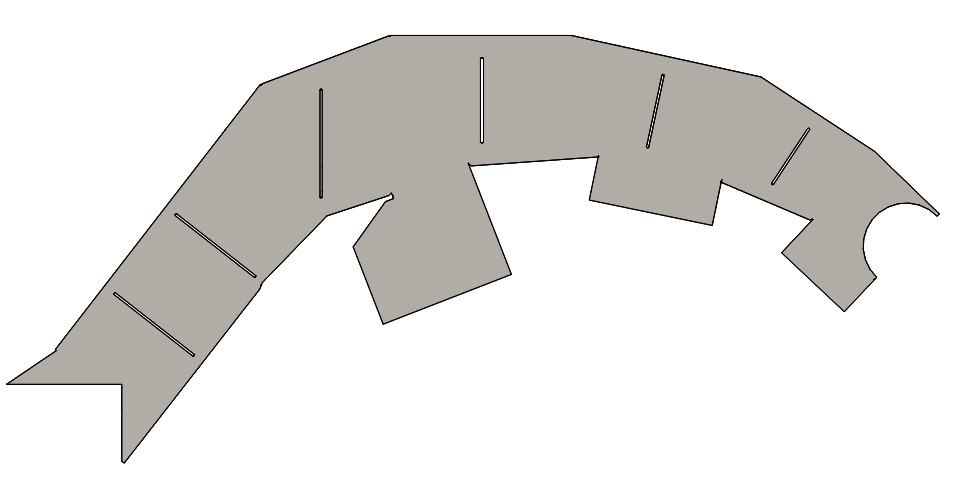

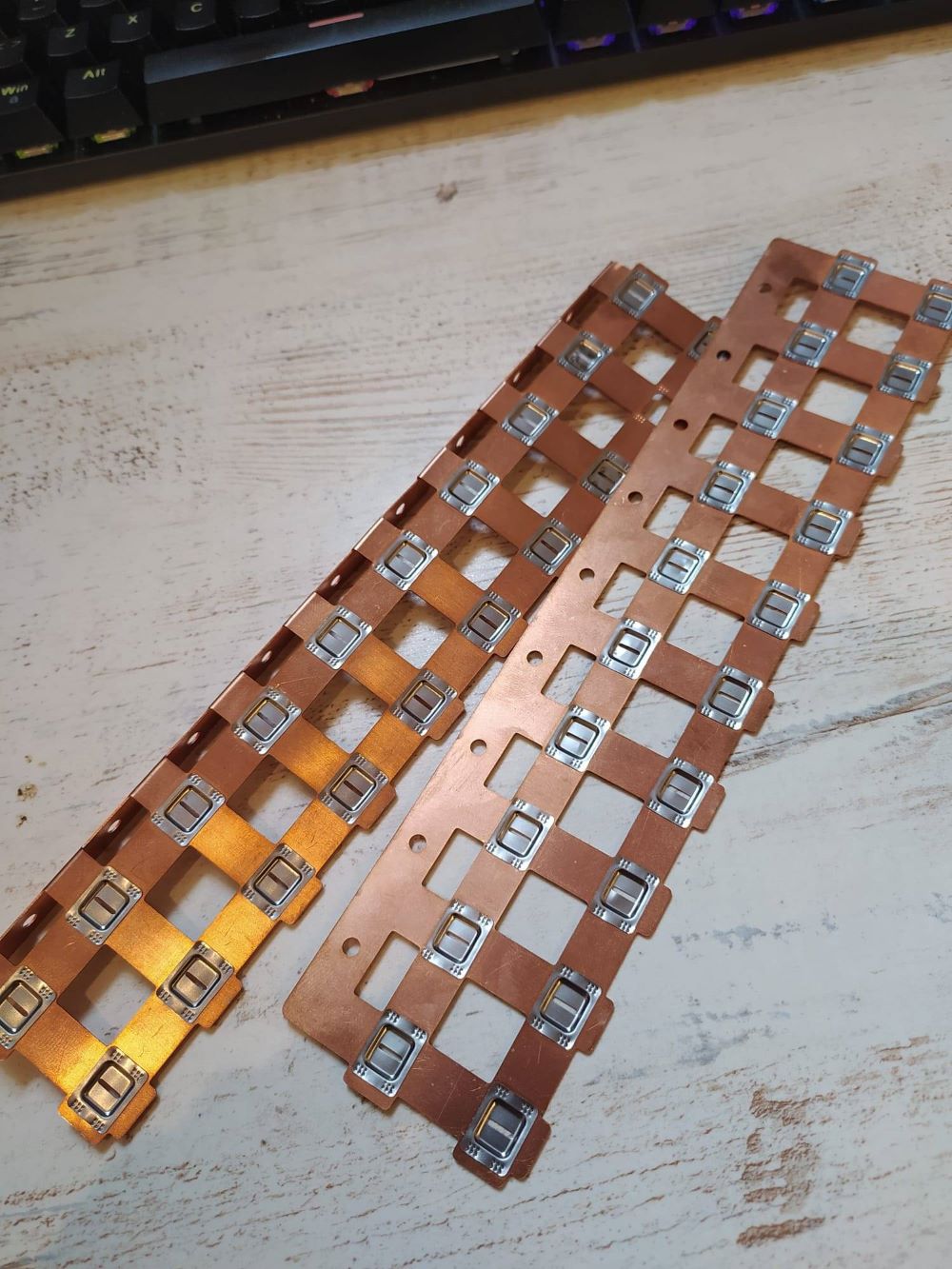

With the solid design finished, it was time to convert the swingarm into sheet metal. For doing this we tried different software such as Fusion360 and Solidworks. Solidworks worked better for us and after many attempts, this was the final result:

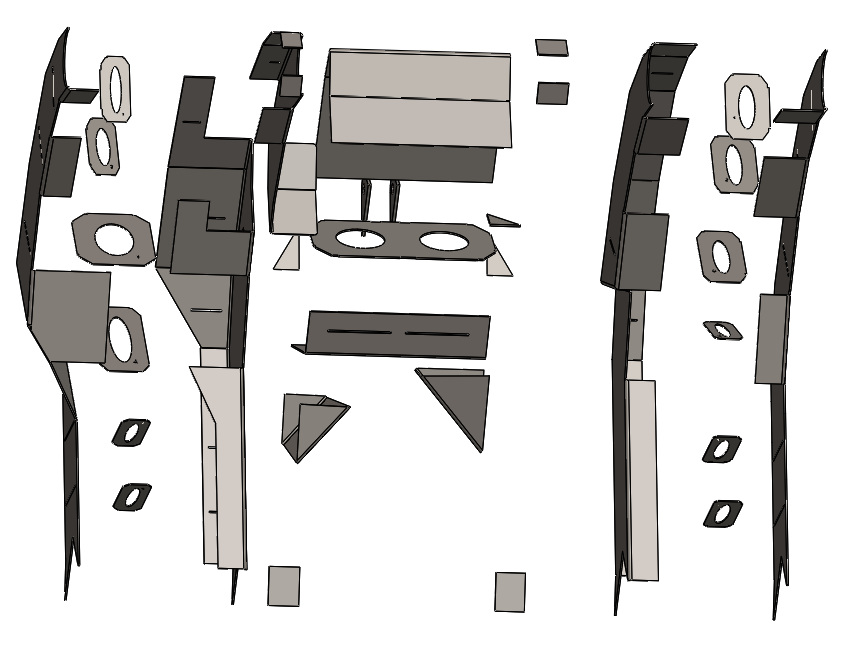

Unfolded swingarm side. This is resulting part from laser cutting.

Unfolded swingarm side. This is resulting part from laser cutting.

To secure the rear axle, two machined parts were designed and welded to the swingarm. On the other hand, aluminum chain adjusters were purchased to adjust the chain tension.

Rear axle

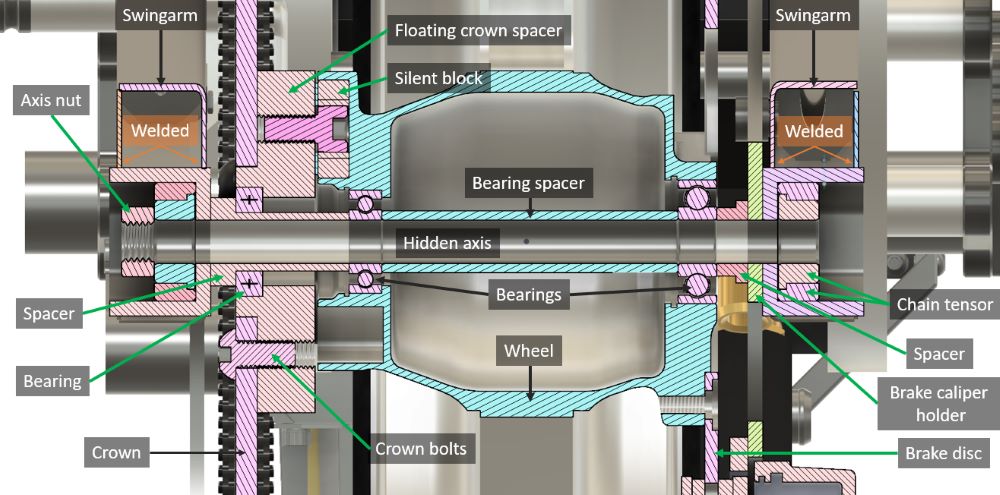

With the swingarm design completed, it was time for the rear axle.

Starting from the right to the left of the image, we have to note that we have 4 fixed elements that are already defined:

- The left swingarm support.

- The right swingarm support.

- The rim with it’s bearings.

- The position of the chain.

These 4 elements are given by the previous decisions made in the design. Therefore, we will apply the same strategy as in the front axle, to go supplementing the spaces based on the measures that we have. To do this, starting from the right to the left:

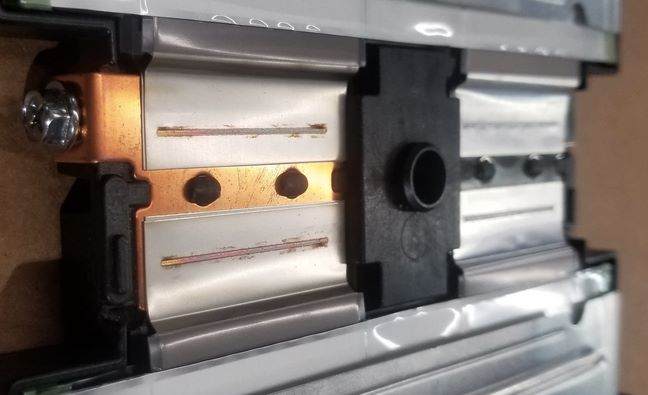

We have the swingarm support together with the chain tensioner. Next we can find the support for the rear brake caliper which acts as a spacer. Keep in mind that the thickness of this piece is given by the position of the disc and the brake caliper. In this case it was a standard thickness of 5 mm so we were able to manufacture a laser cut piece.

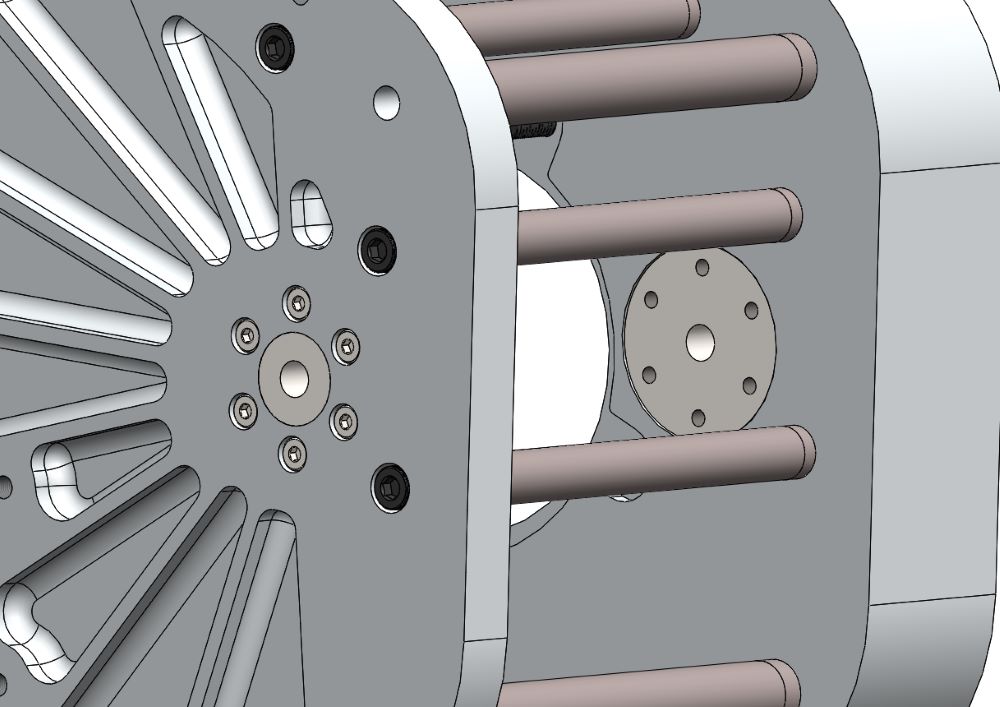

Next we find a spacer that supplements the distance between the brake support and the wheel bearing. Along with it’s the inner spacer for the rim bearing and the other bearing. This parts are from the original rim. Up to this point it’s a normal design, very similar to the original one for this wheel. The difference becomes in the chain support. This rim is designed to work with the chain close to it, but due to the restrictions explained above, we cannot bring the chain closer to the rim, so the sprocket remains separated.

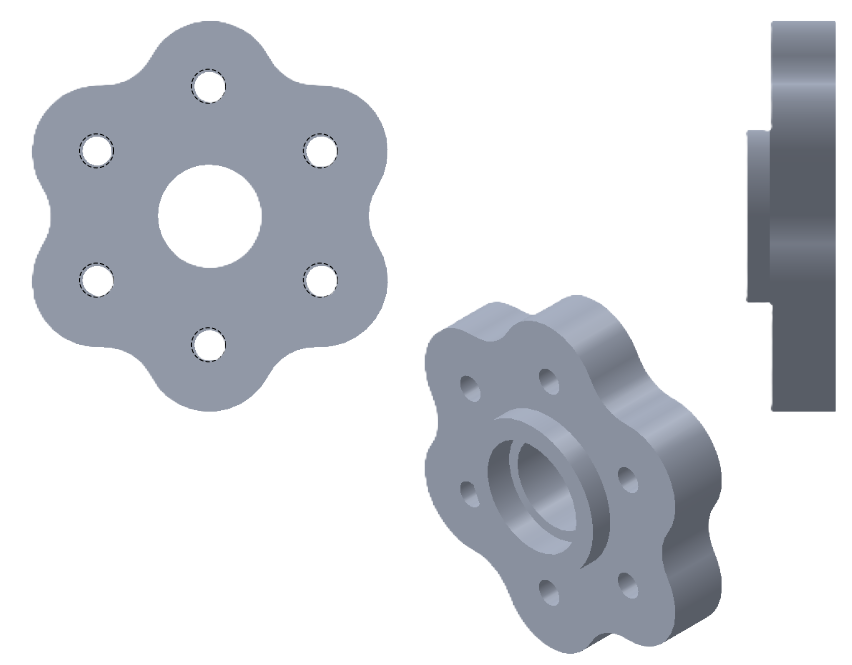

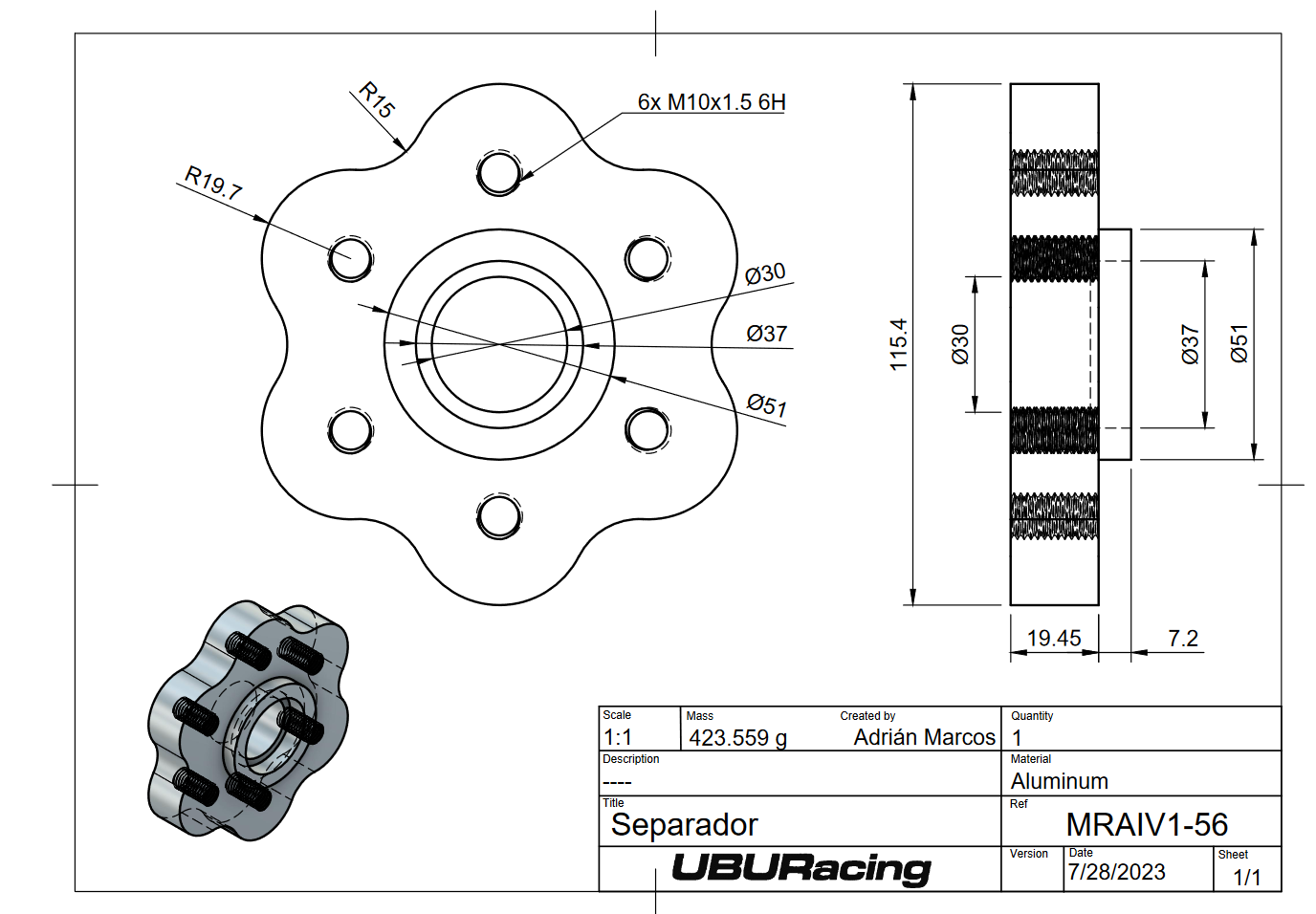

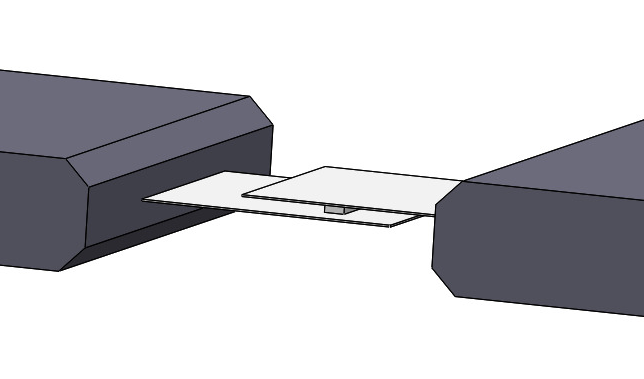

To solve this issue, I designed an aluminum spacer:

This spacer has a bearing aligned with the chain to carry out the load on it. The original design of the rim had 3 silent blocks for drag the rim from the chain. As we didn’t have too much space on the outside of this spacer, I designed the spacer with 6 holes. 3 holes to fix the crown to the spacer with screws and other 3 holes to drag the rim from the spacer. This also keeps it floating with the silent blocks.

Transmission

As mentioned above, there are different alternatives for the design of the transmission for a motorbike. The following are some of them with their advantages and disadvantages:

Direct chain drive: This option is the simplest. It consists of connecting the chain directly between the electric motor and the rear wheel. It has several disadvantages compared to other systems, but the main advantage compensates them. Following the rule KISS (Keep It Simple, Stupid), the main advantage is their simplicity. We should keep in mind that the goal is to build a prototype. It’s a complex vehicle that is designed in a short period of time and we don’t have time to change this systems, we need something working on the first attempt. It’s the main reason why we selected this system.

Transmission with chain/belt/sprocket: This option consists of having intermediate sprockets between the electric motor and the wheel. This has disadvantages such as taking up more space and the loss in performance that this intermediate mechanisms may have. On the other hand, it has two great advantages: the electric motor can be positioned in a different place than usual and the components can be distributed more freely inside the prototype. Also, the size of the crown can be reduced making intermediate reductions. Note that these small electric motors run at high revolutions (usually up to 8000) which makes it necessary to place a large crown on the wheel.

Example of direct transmission with big crown from US Racing.

Example of direct transmission with big crown from US Racing.

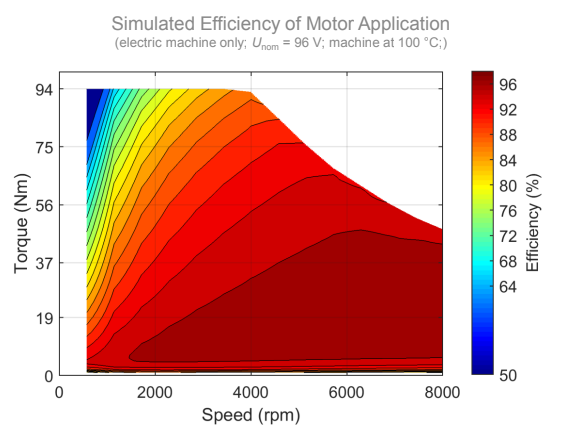

Gearbox: This option offers the most advantages, but on the other hand its the most expensive and complex system. It’s well known that electric motors offer a lot of torque from low revolutions. This is true but with a disadvantage: their performance is not good.

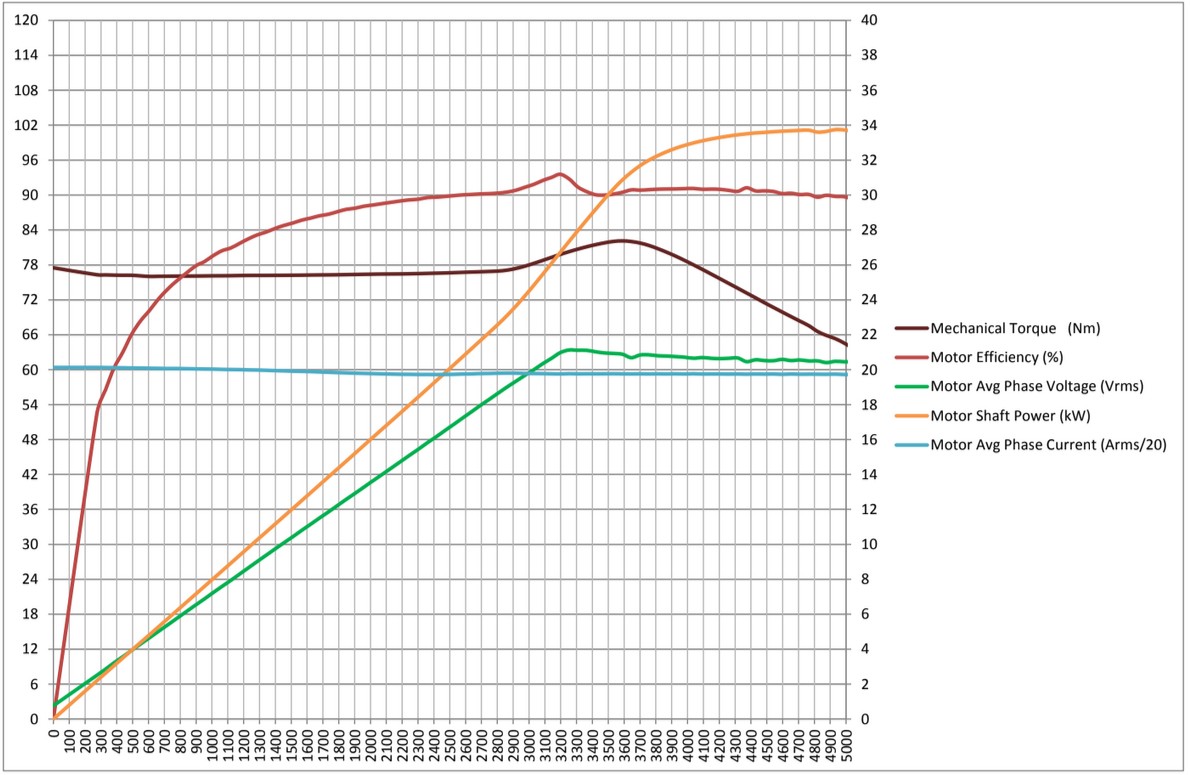

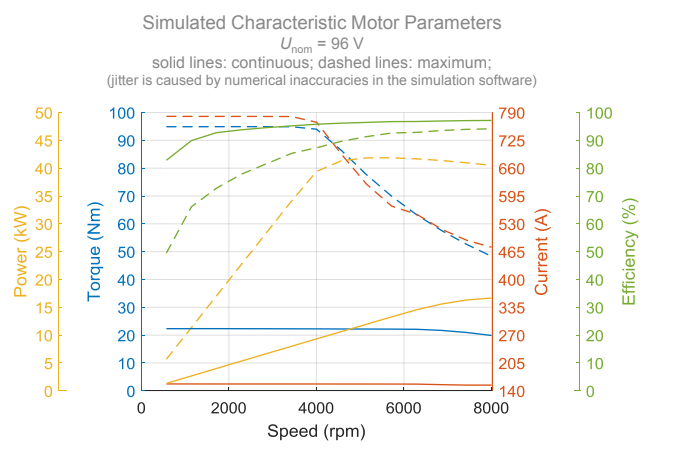

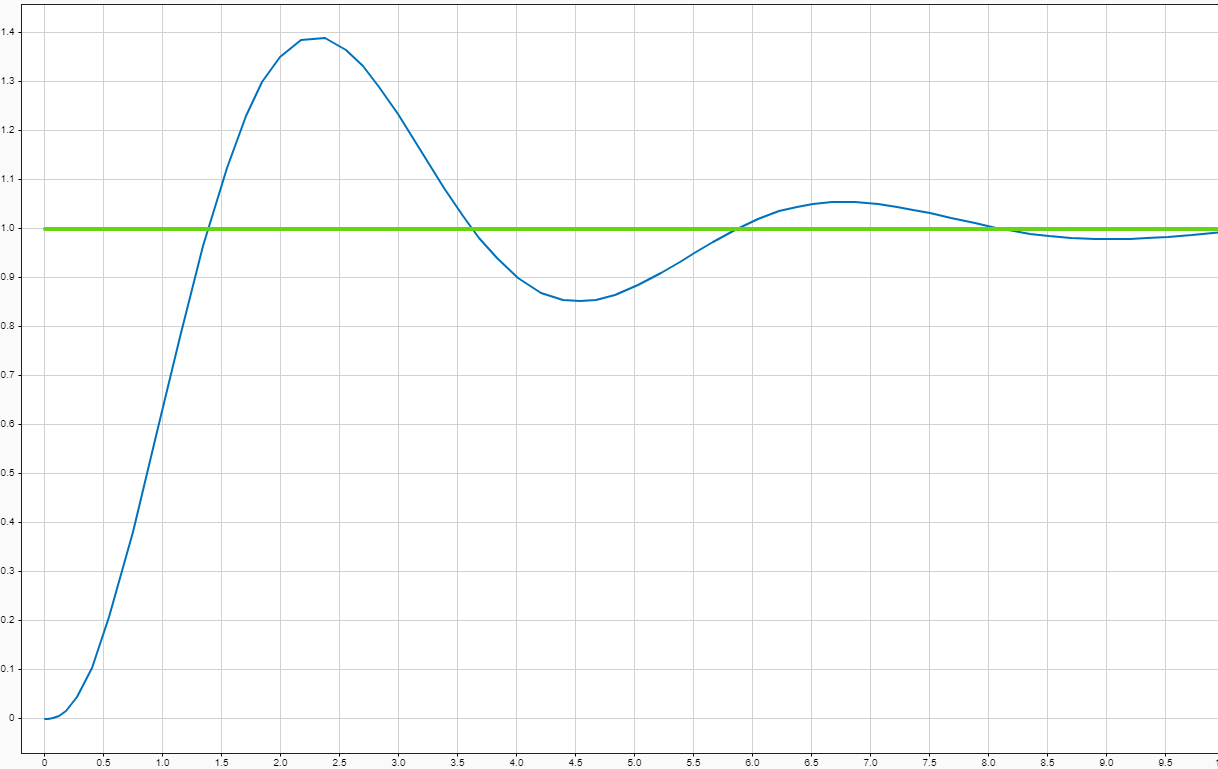

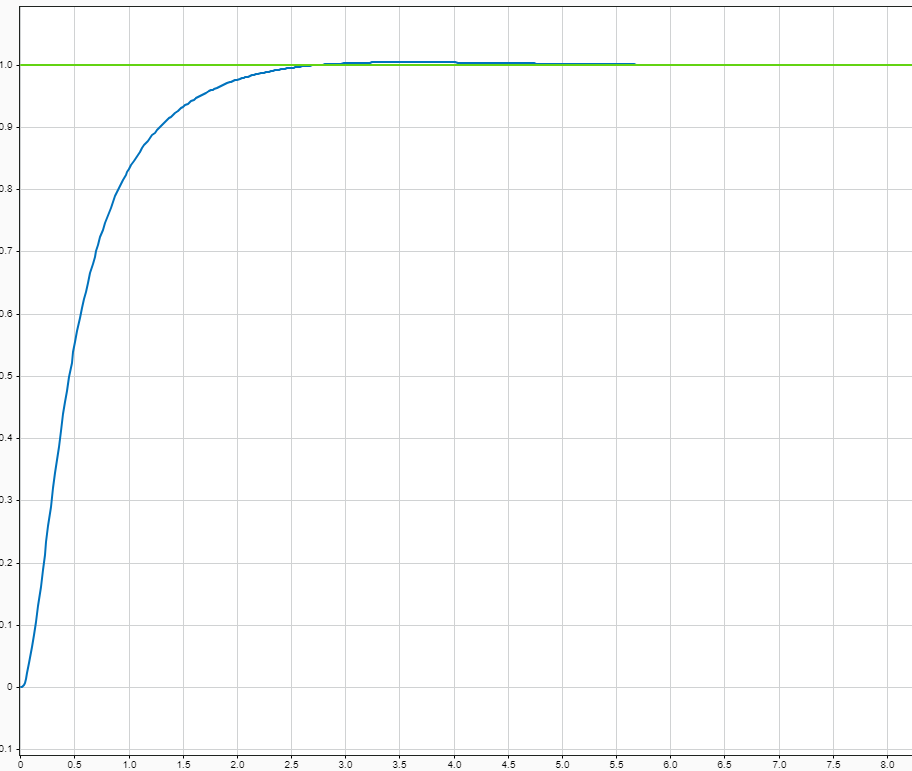

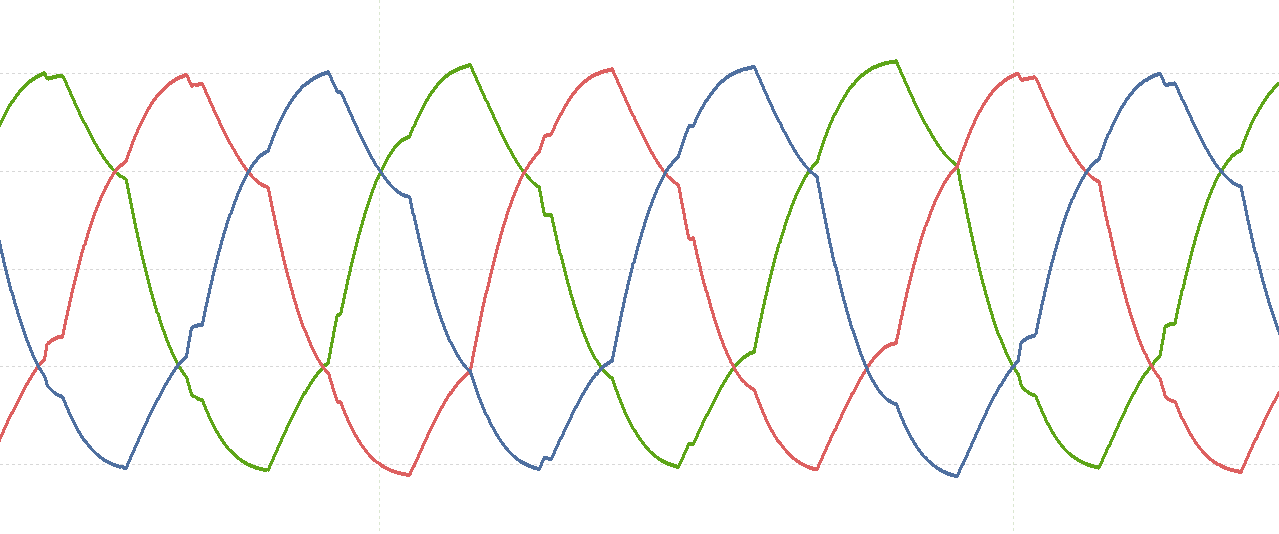

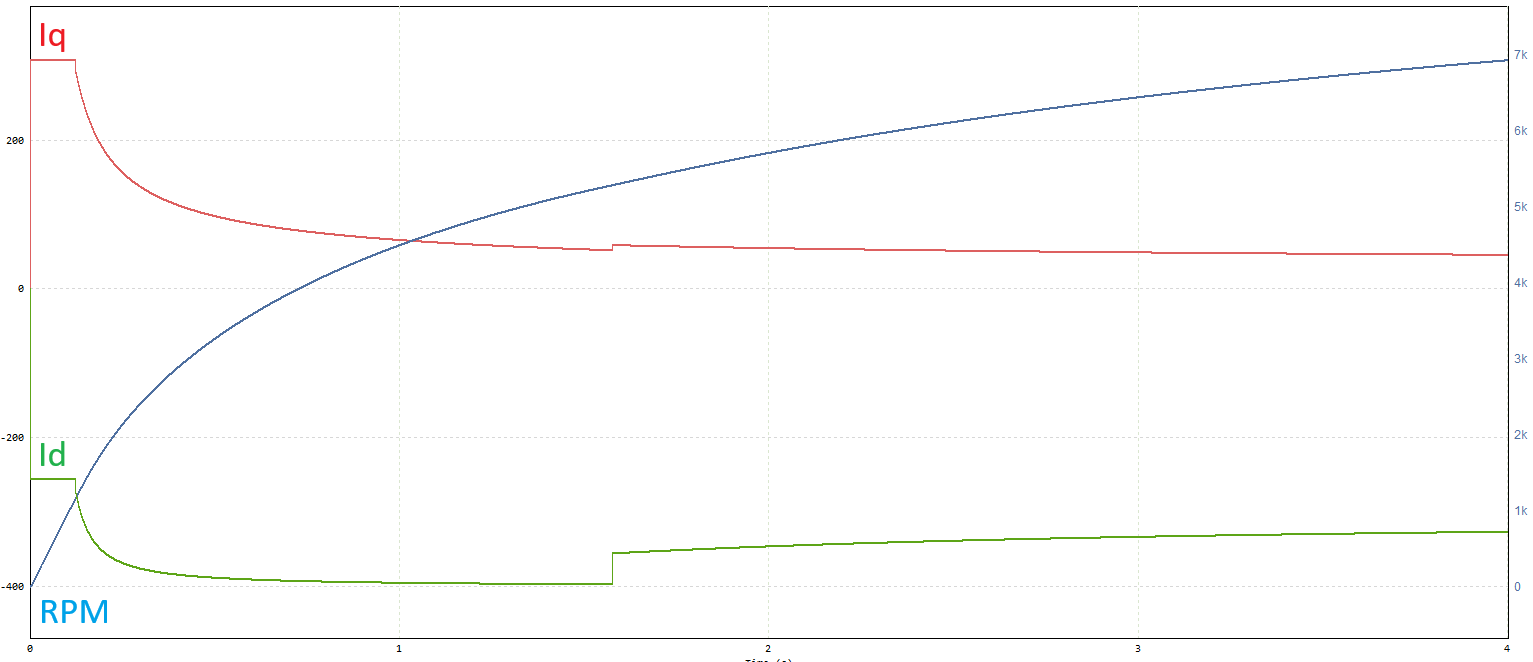

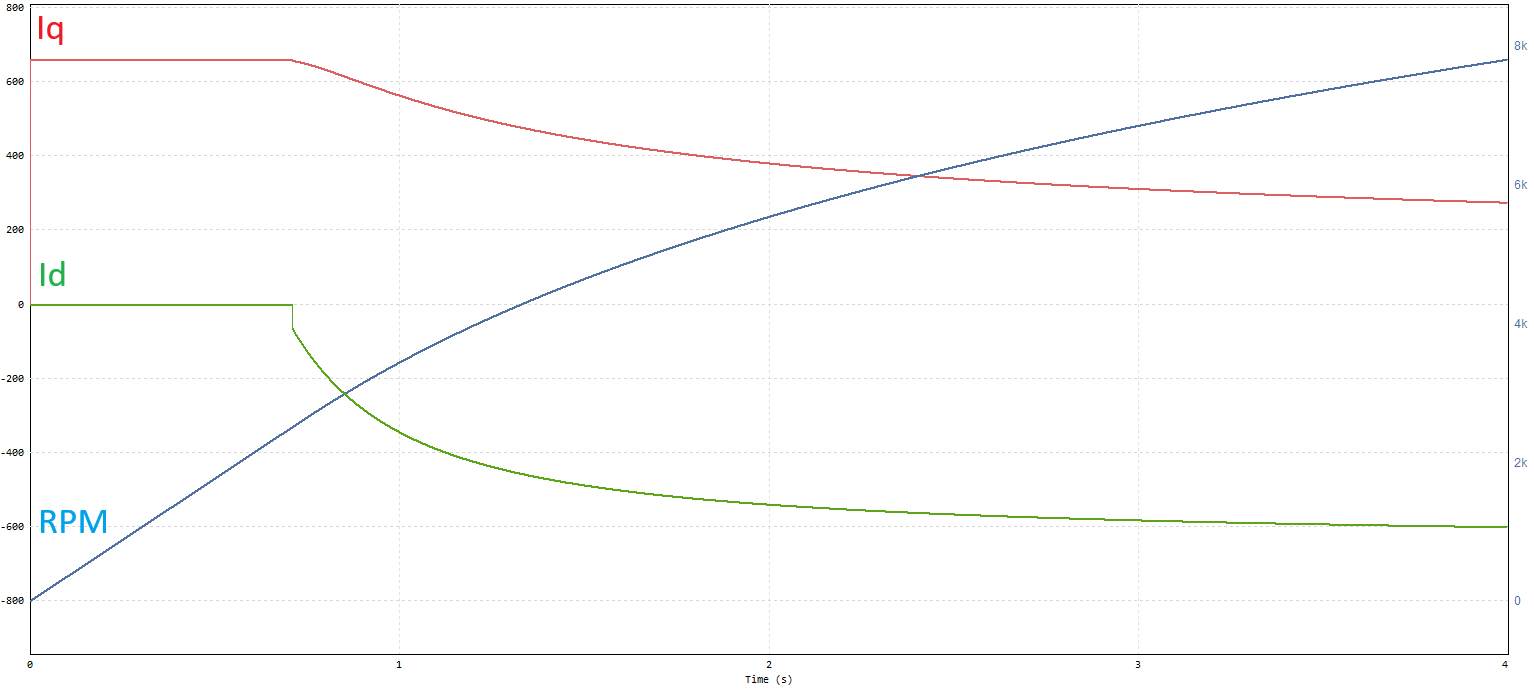

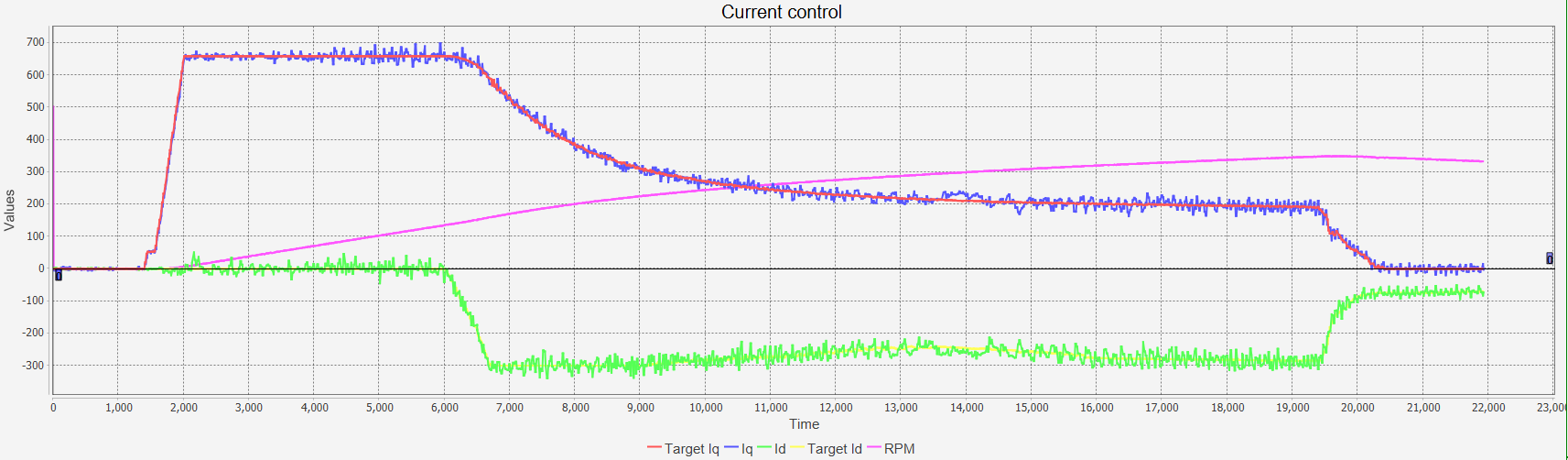

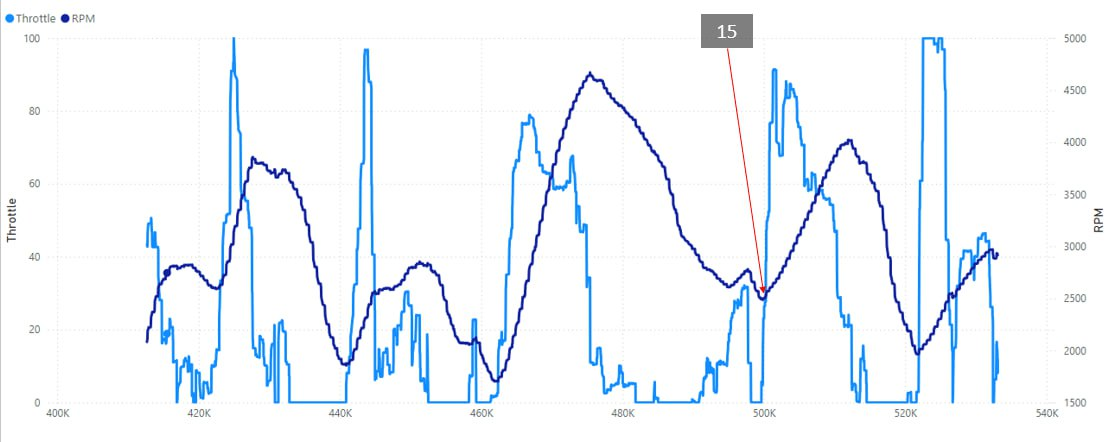

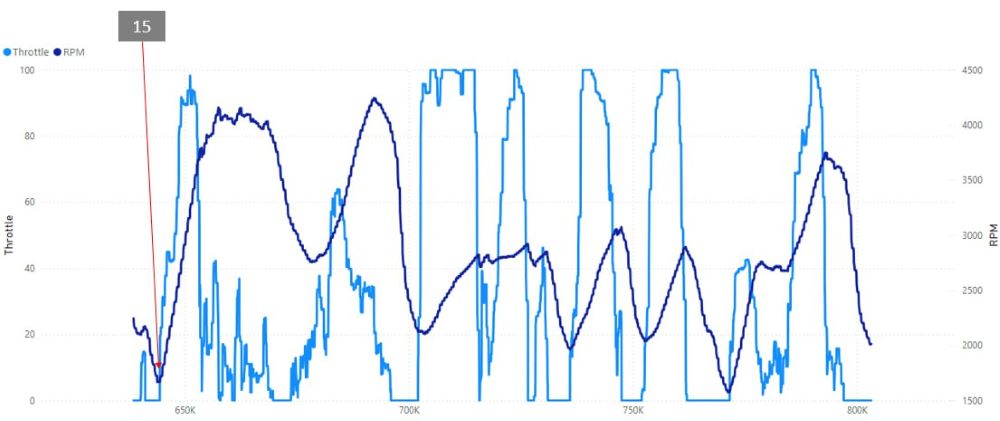

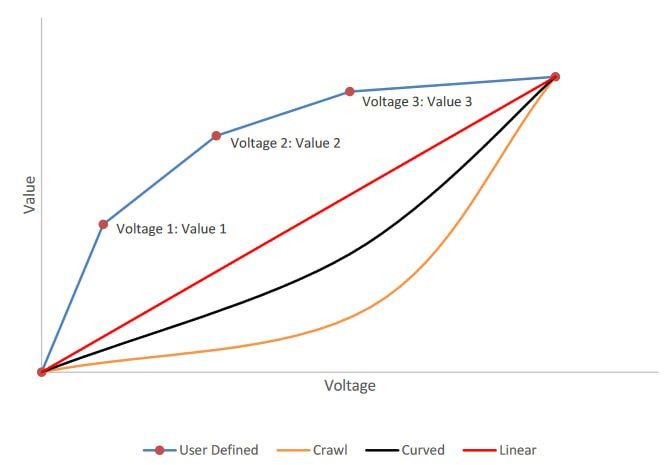

Note the performance at low revs with a high torque demand. It must be remembered that we are in competition and most of the time a high demand is made.

Note the performance at low revs with a high torque demand. It must be remembered that we are in competition and most of the time a high demand is made.

On the other hand, this motors are more elastic than thermal engines, so it doesn’t have much sense to install a gearbox with many gears. From the experience of other teams and editions, they only use the last two gears of a comercial gearbox.

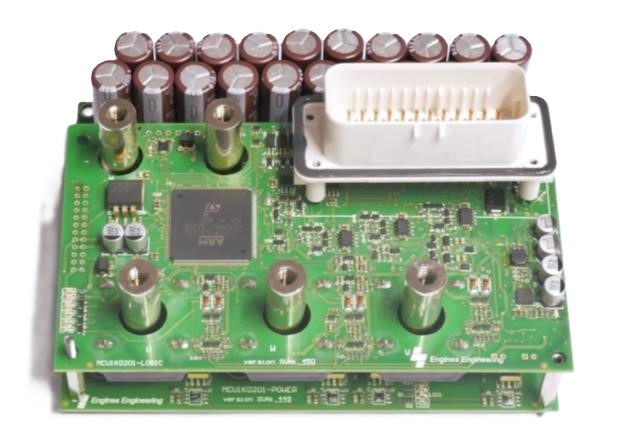

As you can see on the performance graph of the electric motor used in the previous edition (Engiro), the efficiency of the electric motor at low revolutions is close to 50% meanwhile at high revolutions it can achieve 90%. This is a good reason to install a gearbox rather than to get more output torque.

Introducing a gearbox for racing has two handicaps:

- Shifting time: To get effective shifts on a gearbox, especially in acceleration, it needs to be fast shifting between gears, otherwise all the advantage can be lost there.

- Smoothness in shifting: Motorcycles are very sensitive to sudden movements. In fact, in competition, the goal of a gearbox is not only to be fast, it’s also to be smooth between shifts. This means, not generating strong impacts on the tire while shifting.

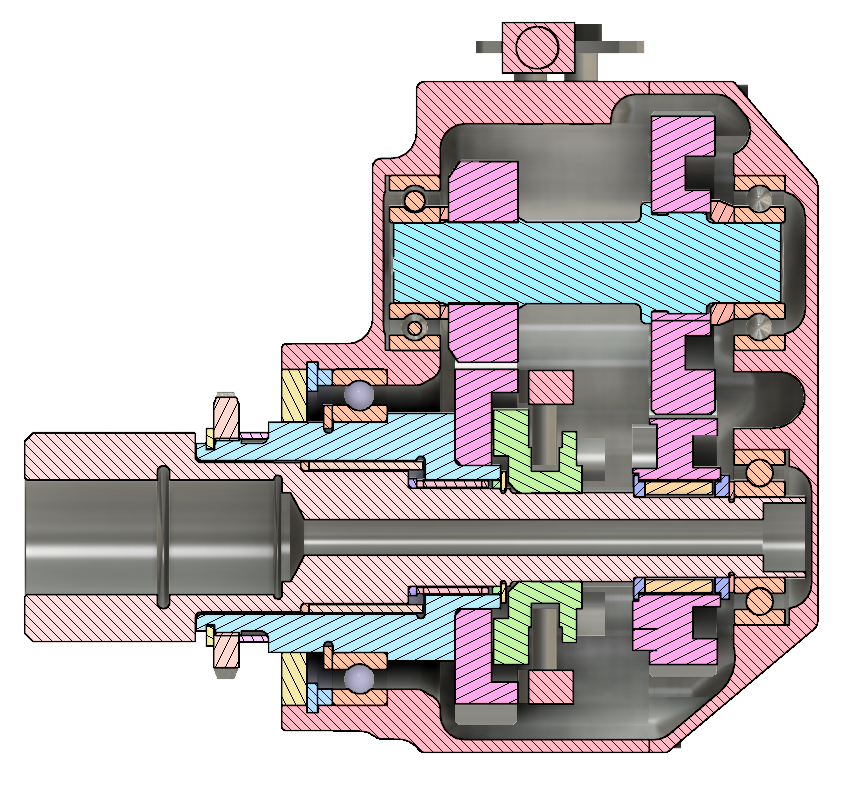

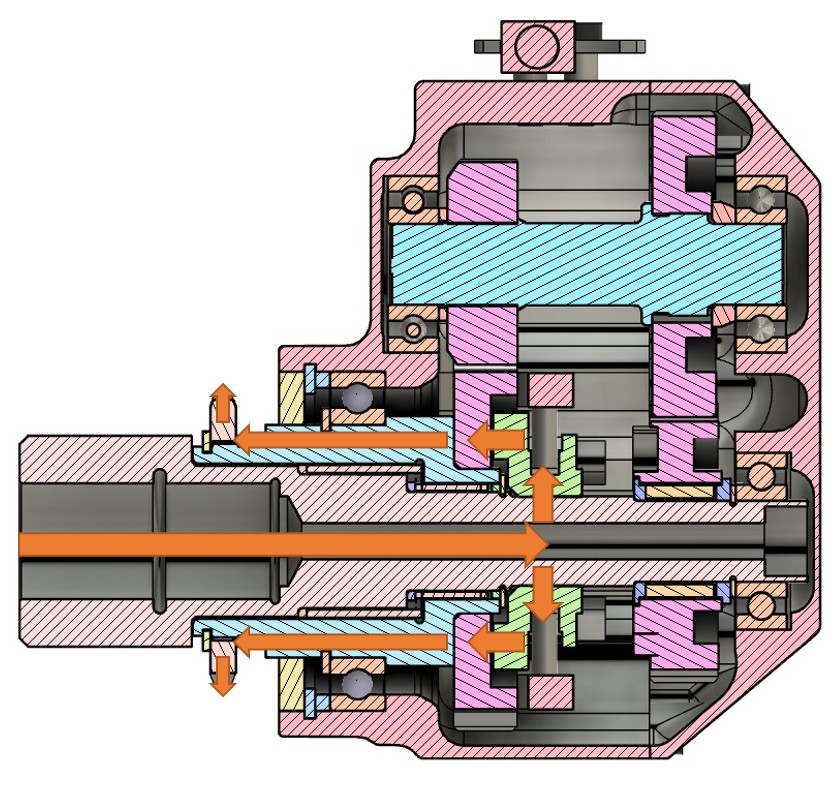

Of course, all this handicaps can be solved but it requires a big amount of testing and time. With this base, we manufactured a gearbox for the previous prototype:

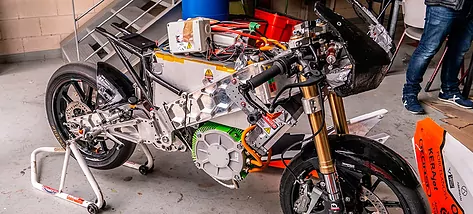

Render of the previous 3D unfinished prototype design.

Render of the previous 3D unfinished prototype design.

This gearbox has two gears, one reduction gear and one direct.

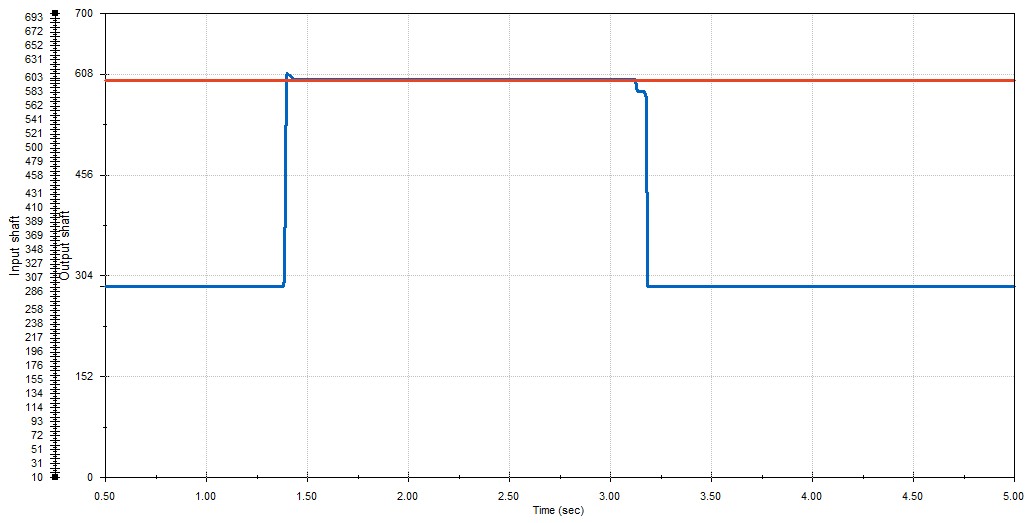

We can see in the blue line the speed of the output shaft when we shift gears. In red, the revolutions of the input shaft.

After testing the gearbox we found two issues:

- The inverter was not ready to gear shifting: It’s not possible to program custom actions to make, for example a smooth shift. We found a workaround to solve this problem using a 0-torque power map to cut the power of the electric motor (like a quick shifter) but we didn’t have enough time to setup it correctly, so the rotor inertia caused a lot of knocks when shifting.

- Gear ratio: Gearbox normally have a small step between gears. The problem, as mentioned before, is that for an electric vehicle we need a big step between gears to make it worth having a gearbox (due to the elasticity of the electric motor). This causes a problem related with the previous one. When shifting, there is a big difference between the speed that the electric motor has and the speed that the electric motor should have on this new gear. If you can’t control this difference, the gears are going to knock when shifting.

These two issues make it complex to make it work in a short period of time and with a inverter that is not designed to support this features, we decided to discard this option for this edition.

Chain

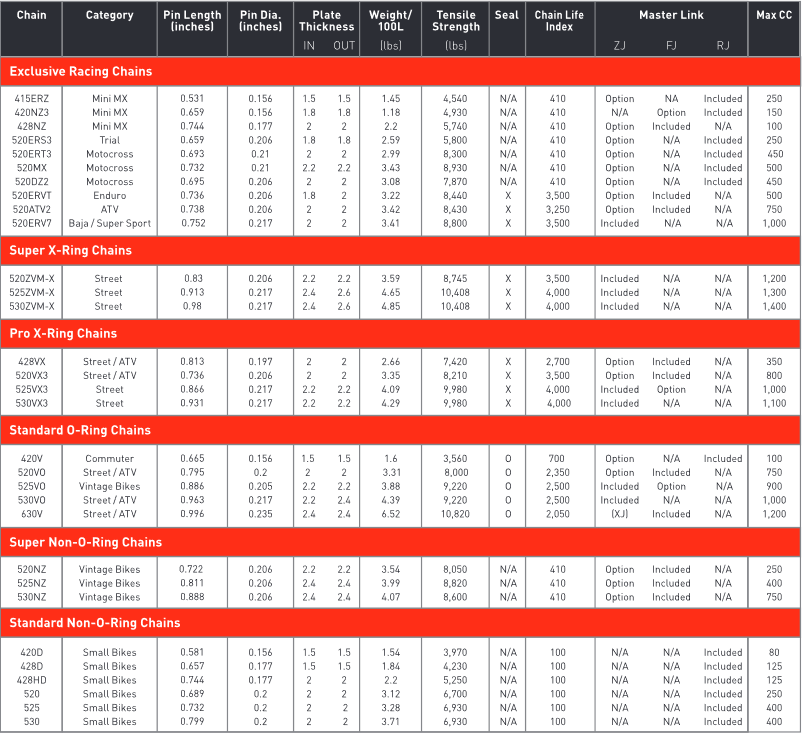

As mentioned before, we are going to use a direct drive system with chain. There are multiple types of chains depending on the use and the force that they can hold.

Source: DID motorcycle chains catalogue.7

Source: DID motorcycle chains catalogue.7

After analyzing the torque that the chain should hold, a 415 it’s enough for the application. The problem was that the 415ERZ is a high quality chain and it’s expensive. We need to buy multiple chains to change the gear ratio for the different tests so this chain wasn’t an option. Instead, we choose a 428HD, it’s stronger than the 420 and cheaper than the 415 with similar specifications, a bit heavier but it was valid for us.

Final design

3D software comparation

Everything presented below is a personal opinion. During this development I had the opportunity to work mainly with two design software: Fusion360 and Solidworks. Some of the differences between this two software that I found during the design of the prototype are:

Fusion360

Pros

- Very fast initial learning curve. The menus and options are neat and clear.

- The PDM system offered by default is very simple and allows collaborative work storing all versions and being able to restore them as if it were a Git repository. In addition, while a user is working on a part or assembly, it is blocked for others avoiding problems.

- The graphical interface is very well designed, modern and clear. The sections of the parts are colored in such a way that each part is perfectly distinguishable.

- I have not tested it but the CAM module for milling must be quite powerful as I heard.

- It opens files from other software such as Catia or Solidworks.

Cons

- For simple assemblies it works well on any machine, it takes a while to start up but it is manageable. The problem comes when you start working with large and heavy assemblies. The increase of RAM usage is exponential and you need a machine with a lot of resources to be able to move it smoothly.

- Many of the options are in the cloud, such as finite element analysis. Personally I don’t like too much how it works.

- When working with assemblies and references between them, many times the references were lost. On the other hand, the contexts used to establish an assembly at a specific time when a part derives from it did not work well for me. I probably didn’t fully understand how it internally works.

- The joints in assemblies are all mechanical. You need to understand how they work to use them correctly and is not as intuitive as Soldworks.

Solidworks

Pros

- Very stable software.

- Moves large assemblies smoothly on a PC with fewer resources.

- Powerful add-ons are available to perform finite element and CFD analysis.

- The sheet metal module is complete.

Cons

- The initial learning curve is a bit harder than with Fusion360.

- It does not have a threading wizard as advanced as Fusion360.

- The 3DExperience PDM is very complete but more difficult to use than Fusion360 for a small project.

If I had to make a decision for a personal project I would consider the purpose. If it is a small project, for 3D printing or machining, Fusion360 would probably be the choice. For larger projects or large companies, I would choose Solidworks without any hesitation. It’s more expensive but perfect for that use cases.

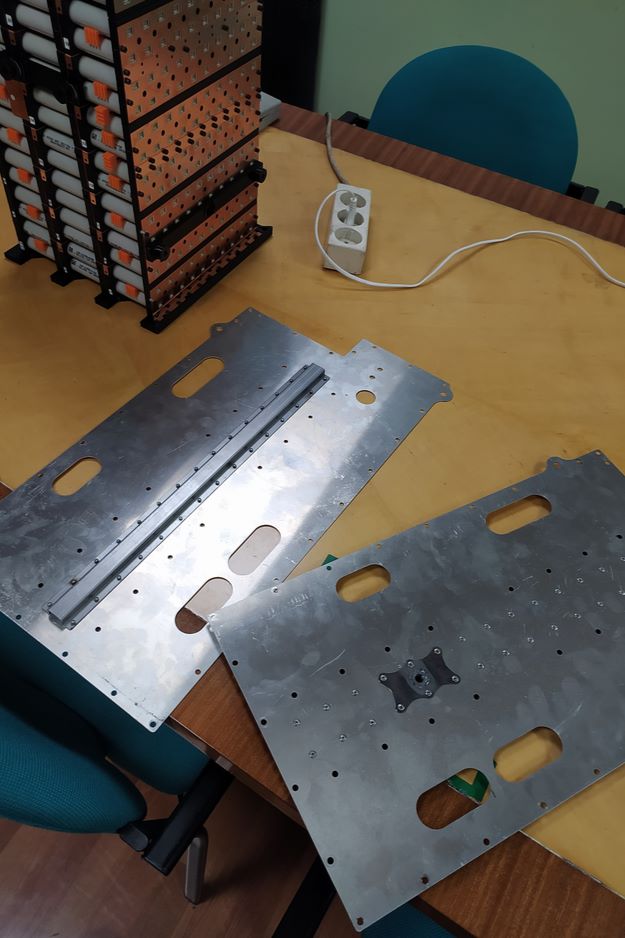

Manufacturing and assembly of the components

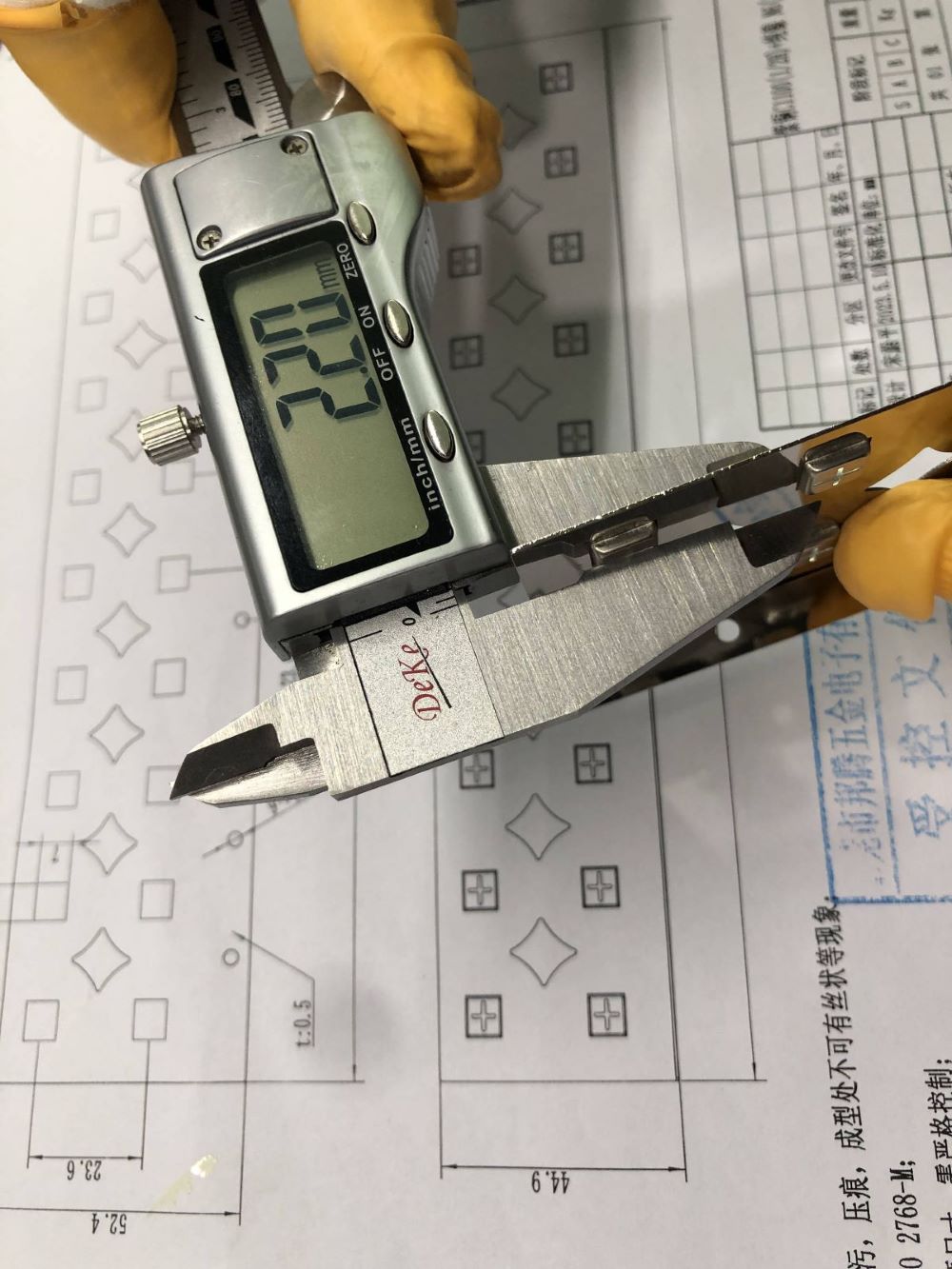

With the design finished, we started manufacturing all the parts for the prototype. We got help from the sponsors for some parts like laser cut and machining. Others were made by us. Of course to get this done we exported all the drawings to manufacture it.

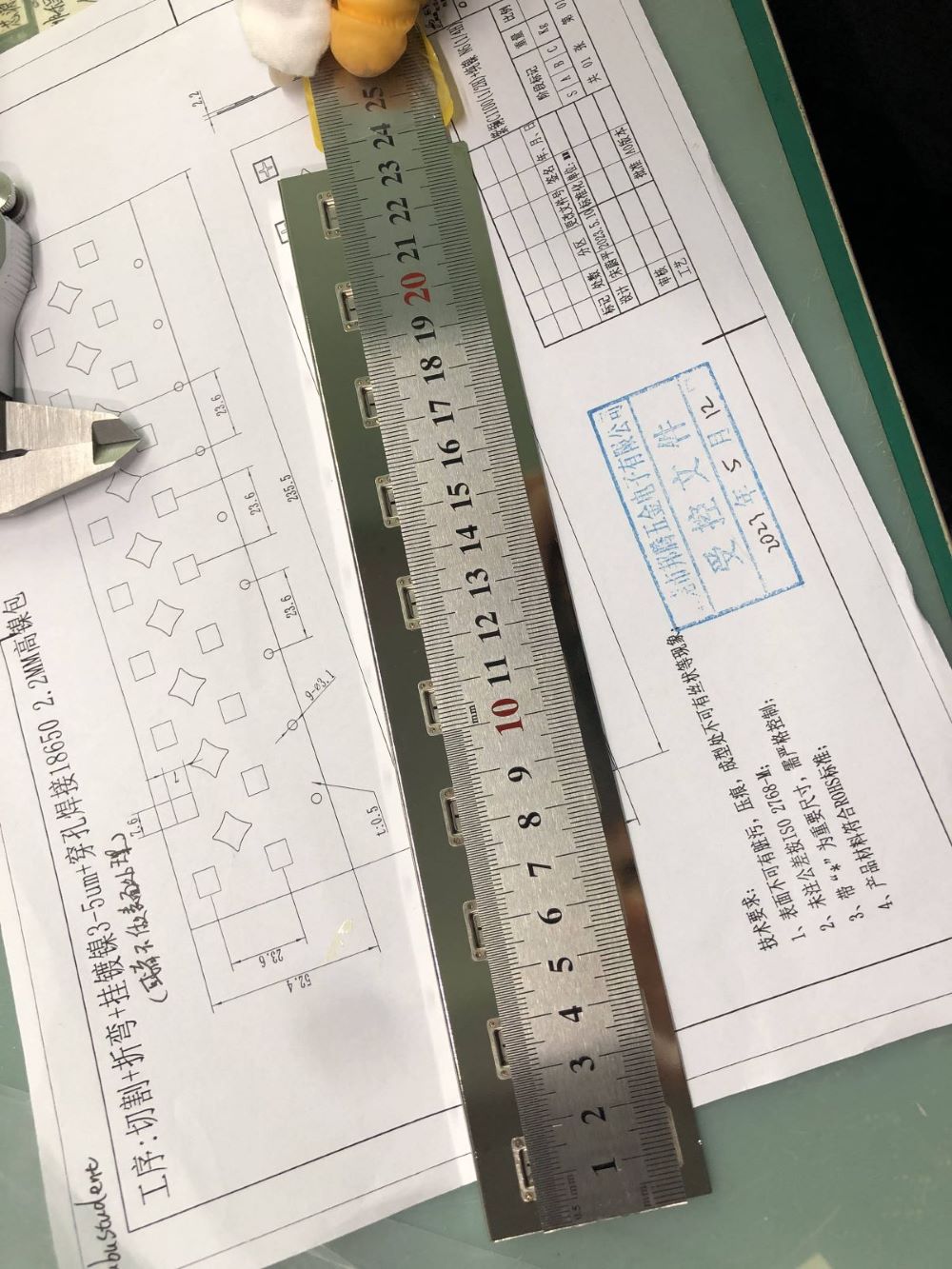

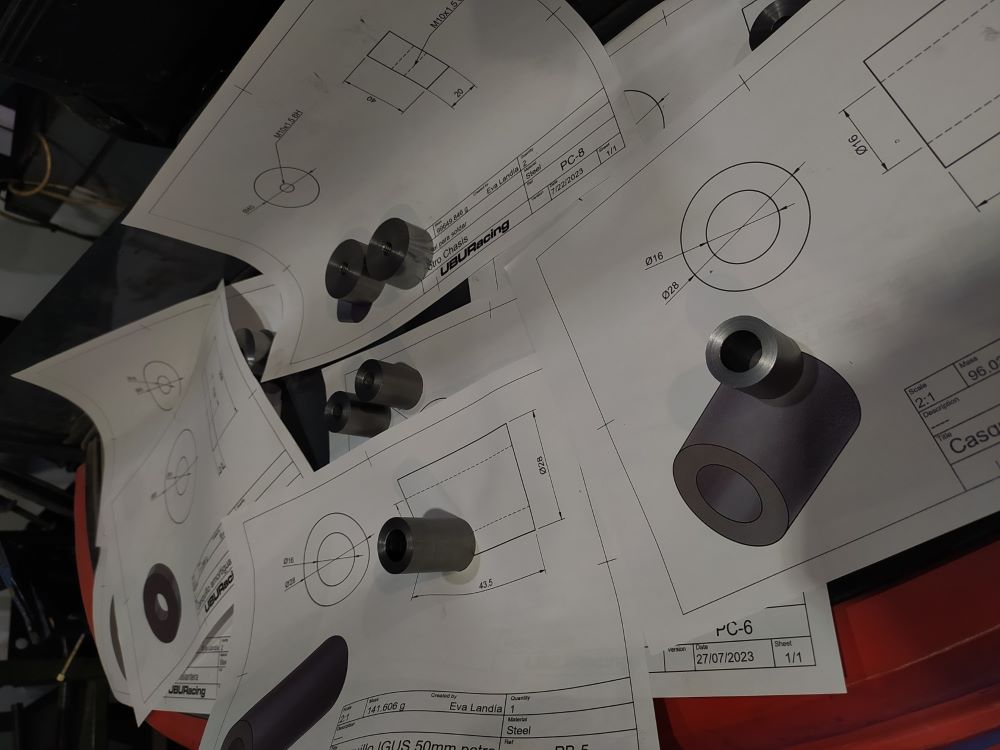

Example of manufacturing drawing

Example of manufacturing drawing

Example of manufacturing drawing

Example of manufacturing drawing

Chassis manufacturing

The chassis is mainly built with pipes, bushings and other mechanized parts. We got the pipes cut with laser from one of our sponsors and the rest was machined by me with a lathe and milling machine.

Manufacturing of different bushings

Manufacturing of different bushings

TIG welding process of the chassis. Note: We machined two bronze bushings to place in the bearing seat so that the diameter is not deformed during welding. In addition, this material will prevent the bushings from seizing.

TIG welding process of the chassis. Note: We machined two bronze bushings to place in the bearing seat so that the diameter is not deformed during welding. In addition, this material will prevent the bushings from seizing.

Swingarm manufacturing

Lower view of the welded swingarm with the jig.

Lower view of the welded swingarm with the jig.

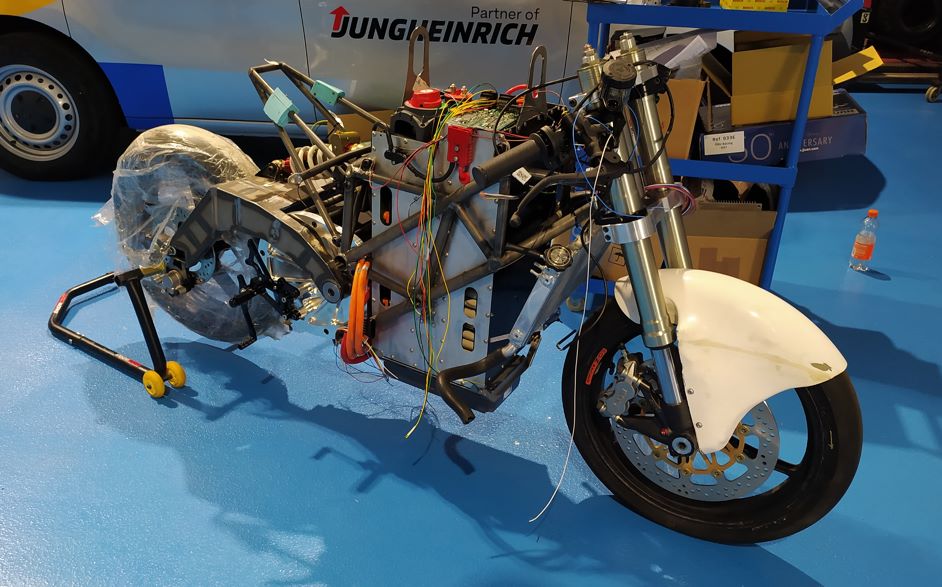

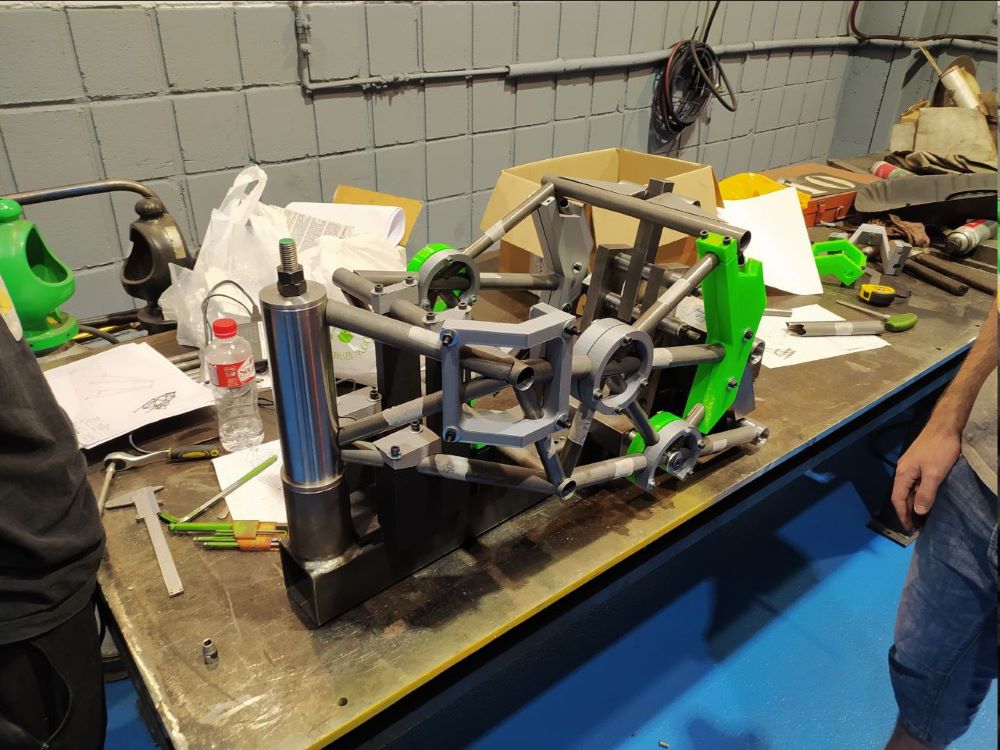

Final assembly

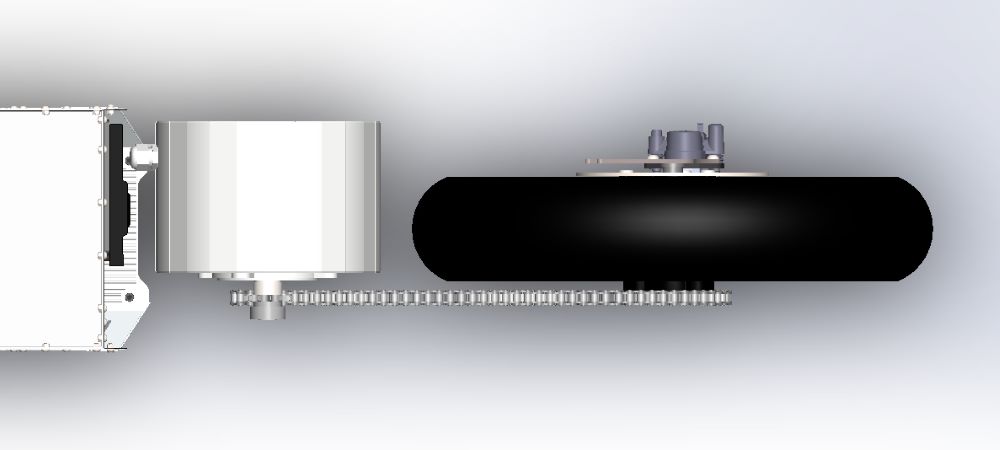

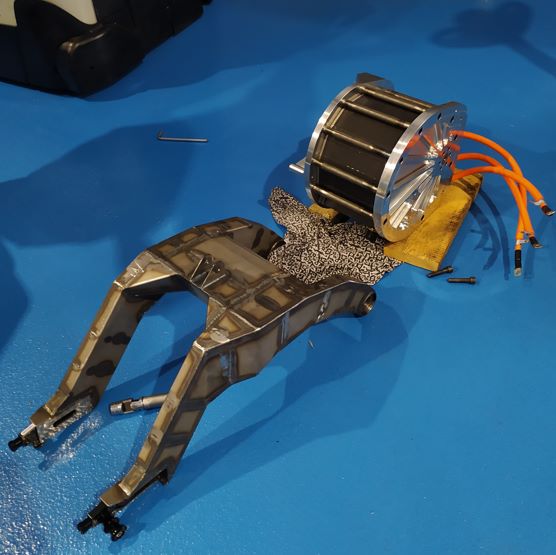

Swingarm and electric motor ready.

Swingarm and electric motor ready.

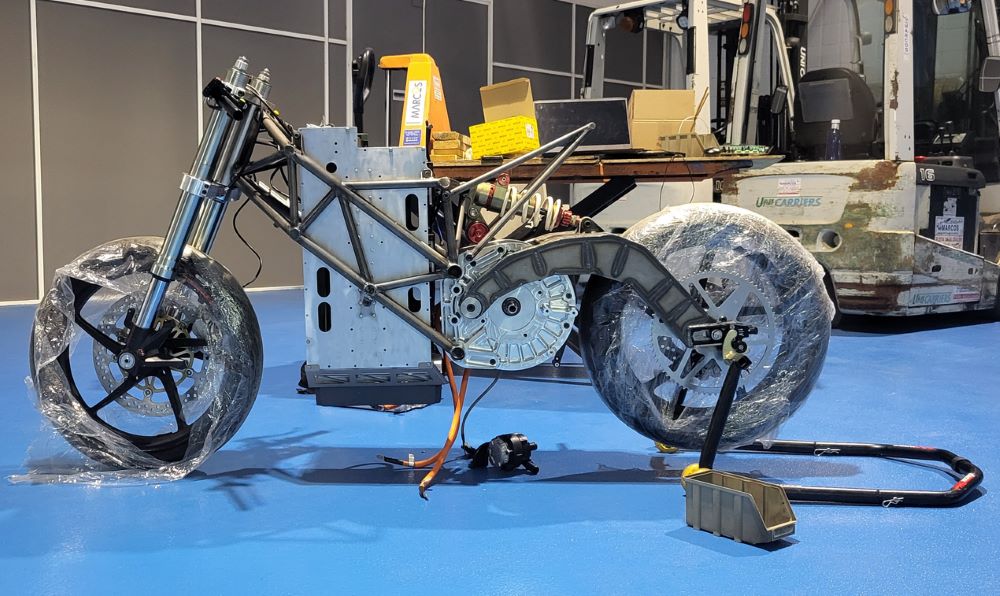

Chassis, electric motor and swingarm ready.

Chassis, electric motor and swingarm ready.

Pre-assembly. Note the empty battery

Pre-assembly. Note the empty battery

Last test on the dyno before road testing

Last test on the dyno before road testing

Last test on the dyno before road testing

Last test on the dyno before road testing

Fairing

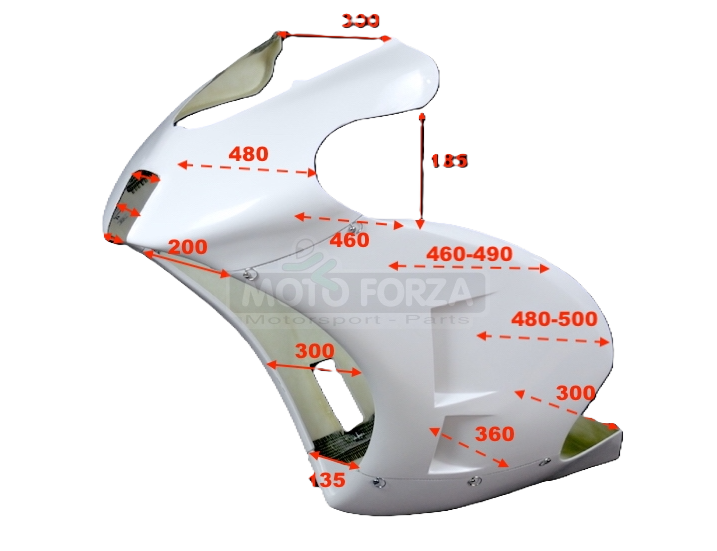

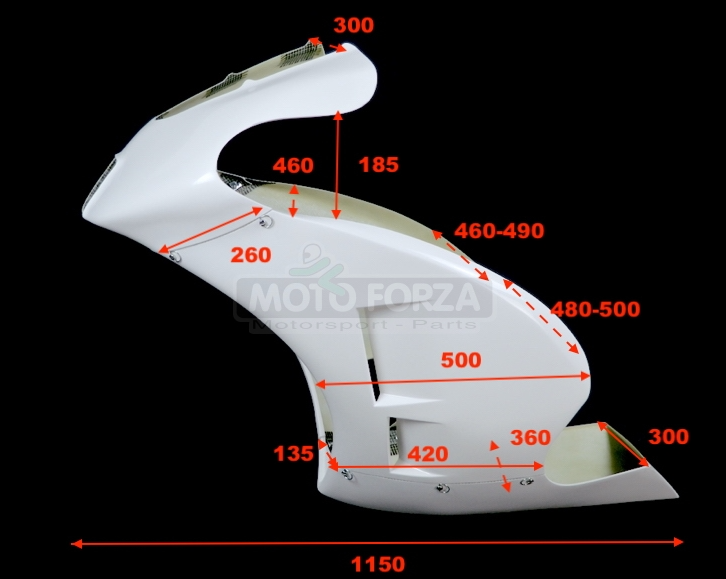

For the fairing, our initial idea was to design and manufacture it completely by ourselves. For this it was necessary to manufacture molds (3D printed or machined in wood) and apply the material (fiberglass or carbon fiber) on them. Due to lack of time we could not make the fairing ourselves so we decided to buy one and adapt it to our prototype.

For this, due to the dimensions of the bike we decided to use a Moto2 fairing. In the previous edition we had used a fairing from Moto3 and the prototype was much smaller so we assumed that the Moto3 fairing would be too small for our current prototype.

It should be noted that the fairing of a Moto2 was big for this prototype too but there wasn’t middle size and we had no time to loose.

The process of adapting this fairing was artisanal, manufacturing brackets to hold it to the prototype. We had to open the keel because the inverter didn’t fit inside and close some air intakes that the fairing had and we didn’t need.

Cutting the tank cover to make it narrower

Cutting the tank cover to make it narrower

3D scan

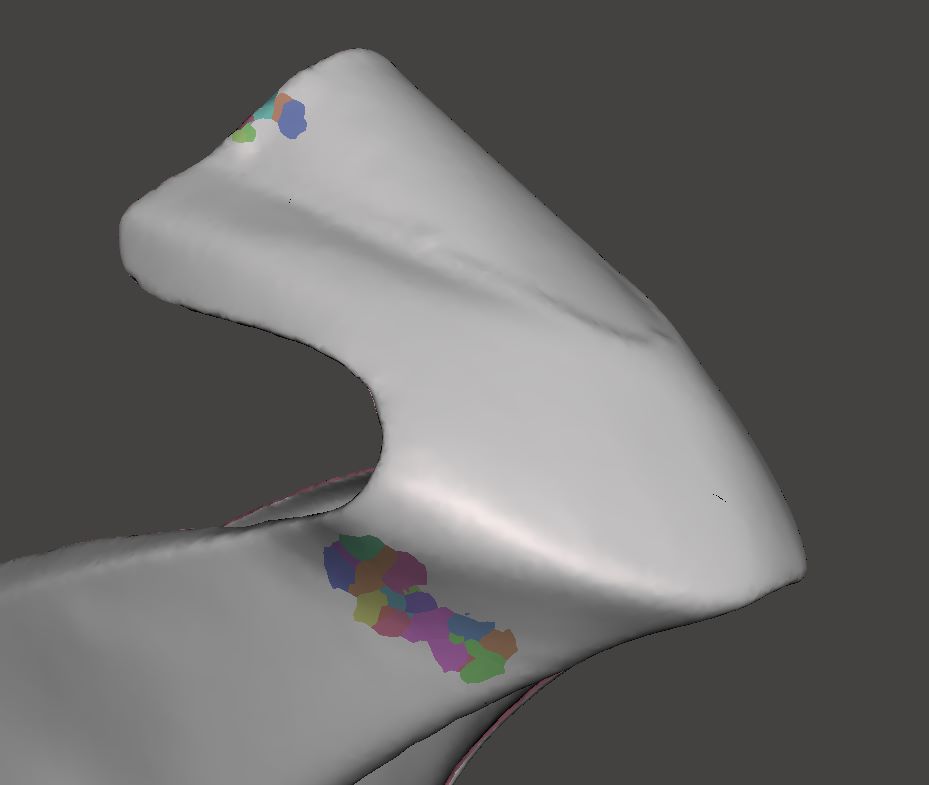

After manufacturing the fairing I would like to check on the CFD how efficient our fairing was. Also we needed it to create some gift for our sponsors so I scanned the fairing with a Revopoint 3D Range scanner.

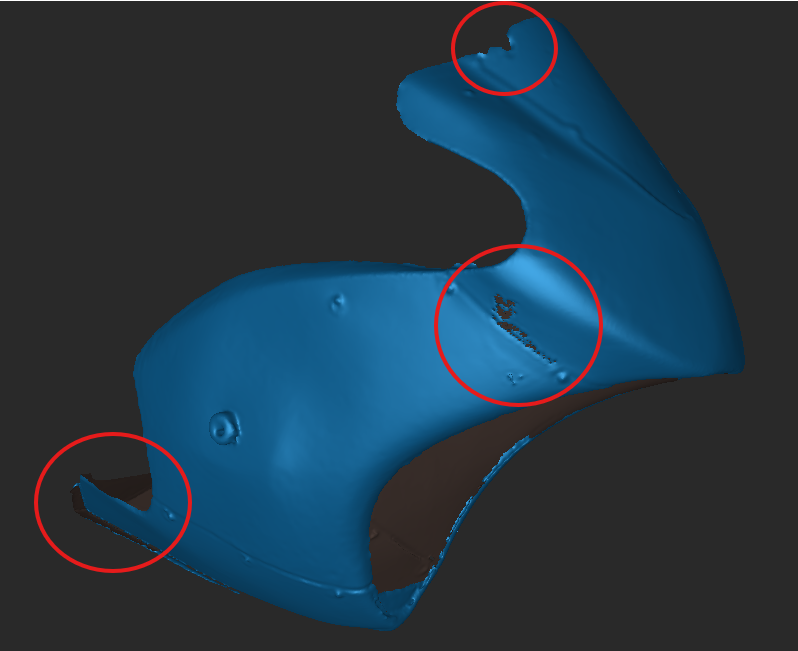

It’s surprisingly easy to use. You have to keep in mind that you need matte surface (you can sprinkle talcum powder) and be careful with dark and shiny areas. With the right lighting and surface conditions it works very well. After scanning it, you can get something like this:

Result of the scan in Revo Scan 5 software

Result of the scan in Revo Scan 5 software

As you can see, the mesh is not perfect and it’s only one layer. We need to work on it to correct the issues and generate a solid body. We wanted to print it also on a SLS printer so surface is not valid for that purpose.

With Autodesk Meshmixer, we can edit the mesh. After a few hours, I got this:

This process was done with all fairing parts, the tail, tank cover and front mudguard. After that we got this result:

FEA (Finite Element Analysis) & CFD (Computational Fluid Dynamics)

TO-DO

Result

Electronics ⚡

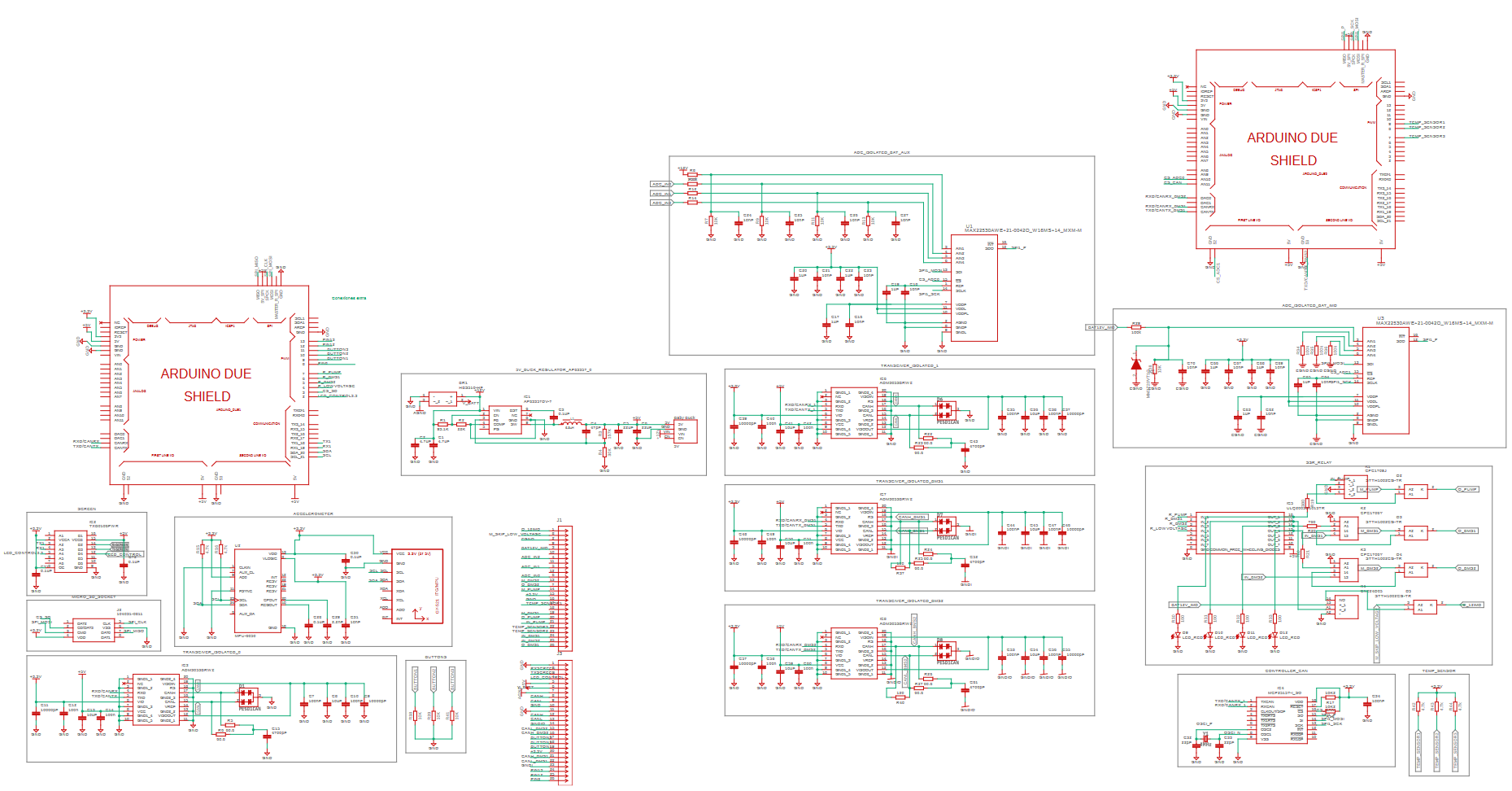

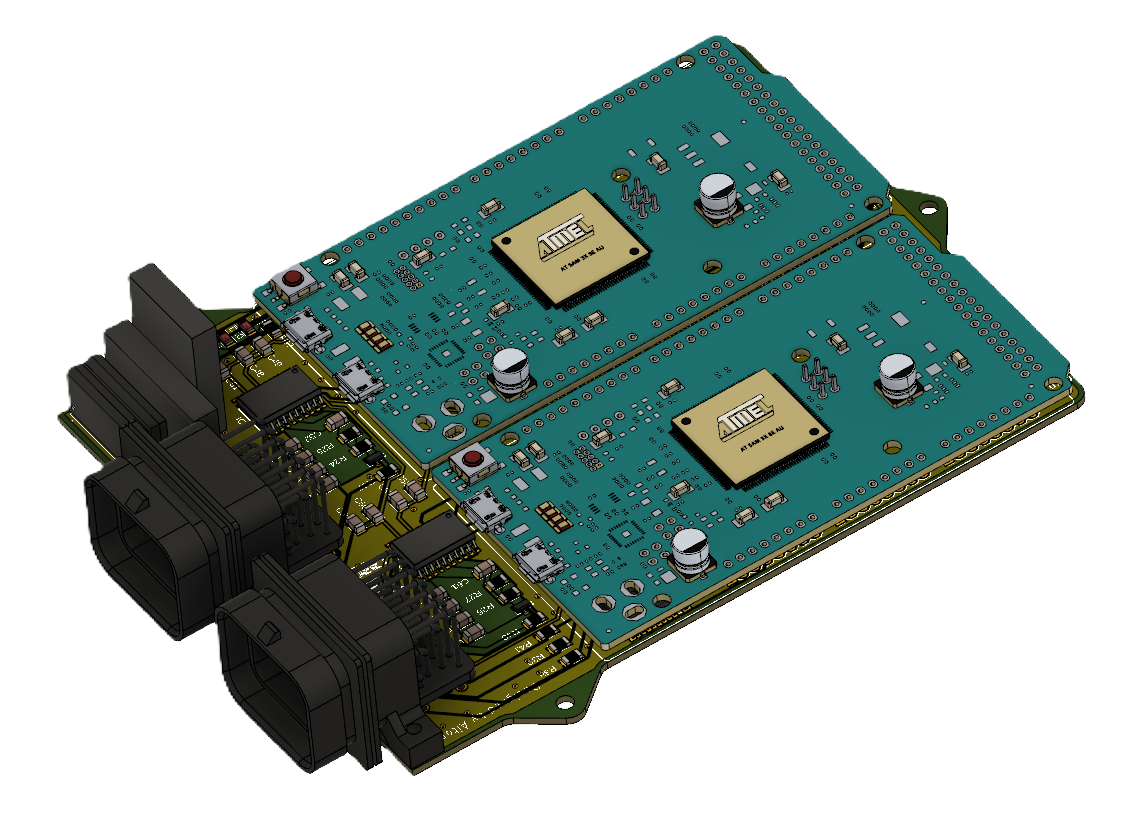

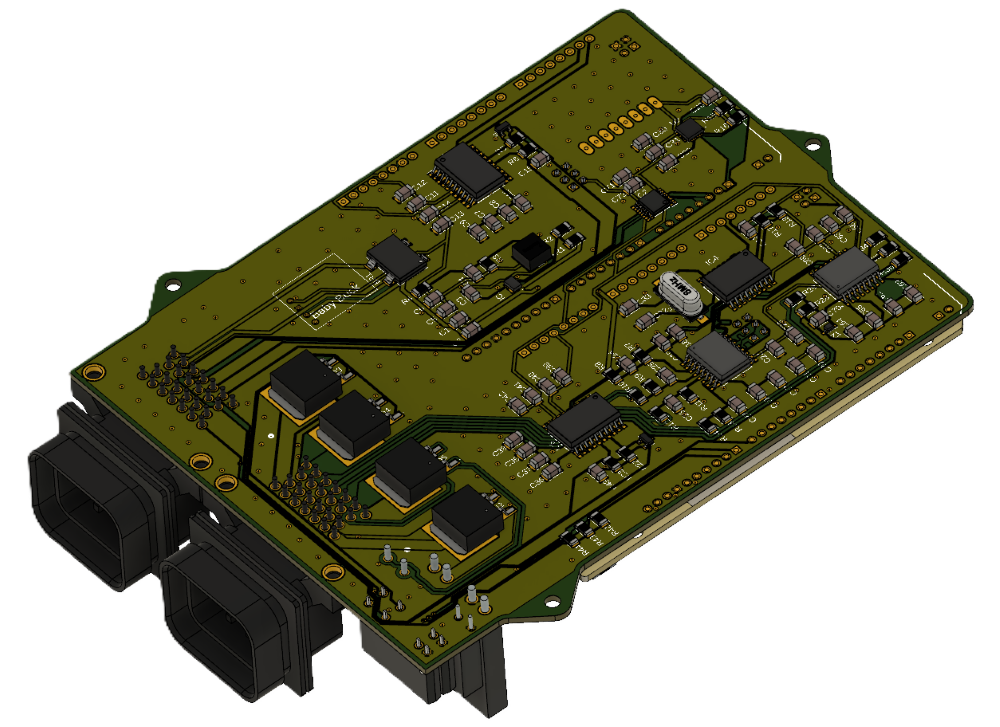

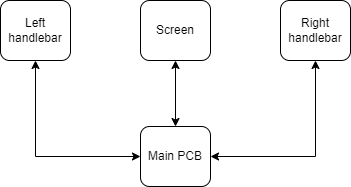

In this section, I will focus primarily on two topics: the vehicle’s electrical system and the telemetry, both of which we developed in-house.

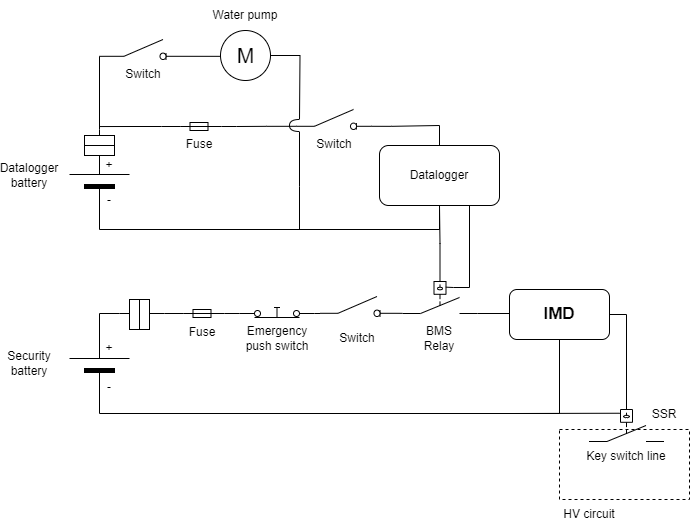

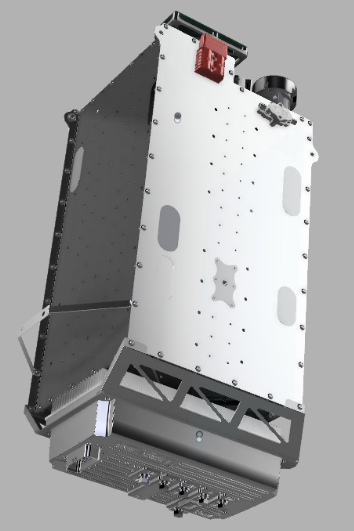

Security measures

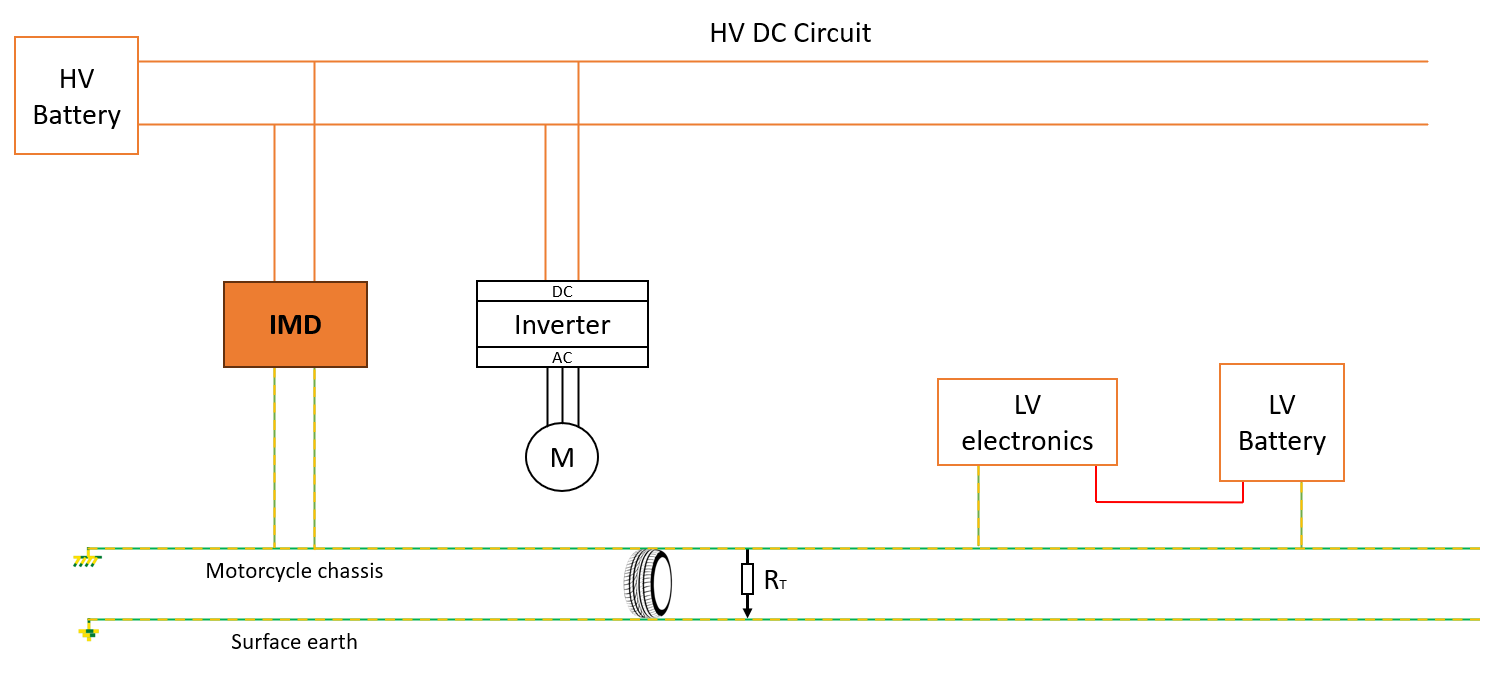

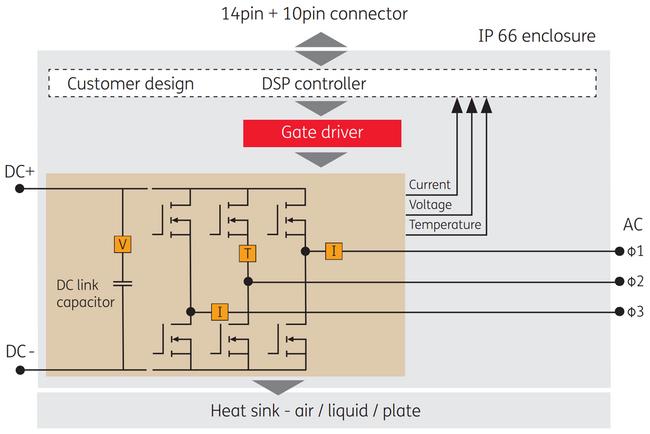

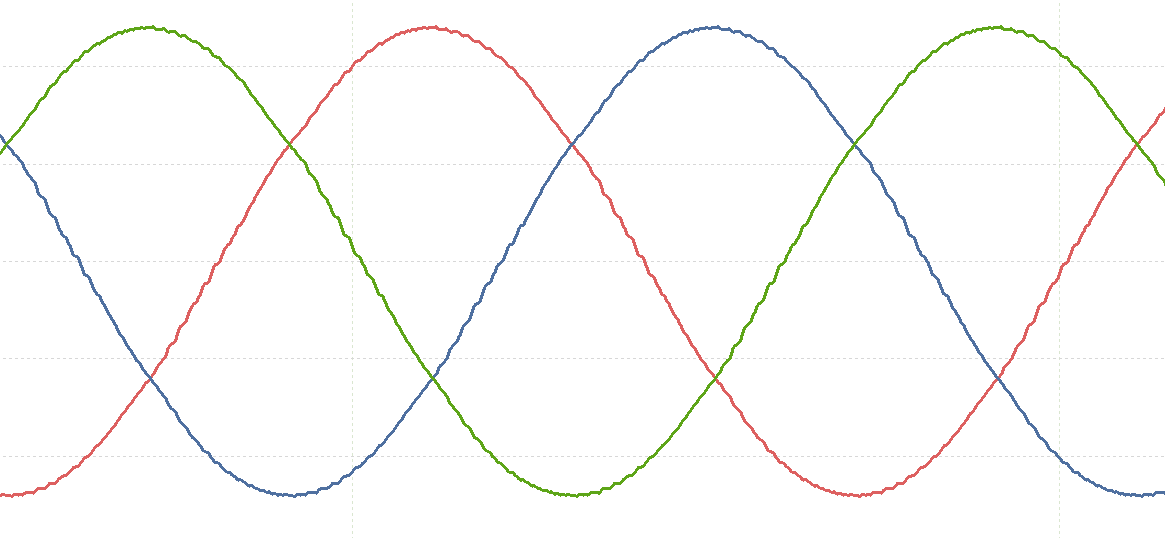

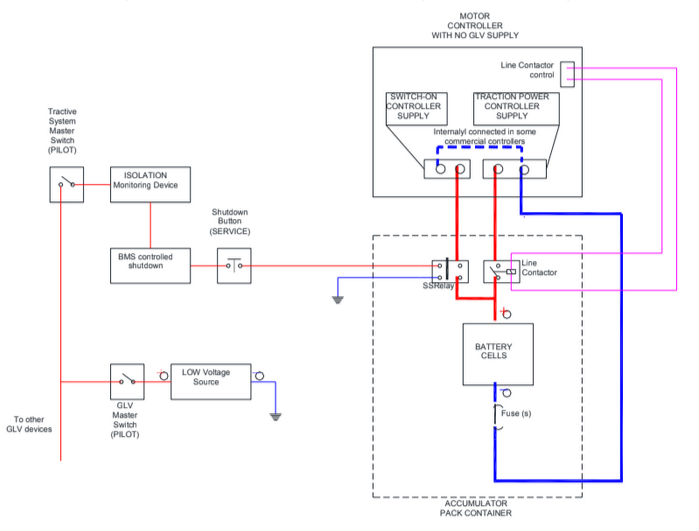

One of the most critical aspects of an electric vehicle is its safety system. In our case, we use a battery with a peak voltage of 117V, capable of supplying 900A of continuous current with even higher peak outputs. The organization requires two main safety components to be installed: the IMD (Insulation Monitoring Device) and a safety circuit, which we’ll discuss later.

By regulation (and common sense), the vehicle has two separate electrical systems: HV (High Voltage) and LV (Low Voltage). In a conventional vehicle with a 12V battery, the chassis serves as ground, meaning the negative terminal is connected directly to the frame. However, in high-voltage vehicles, this approach is only partially applicable.

The high-voltage system is directly connected to the battery and must be a “floating” system, completely isolated from the vehicle chassis. This configuration requires two different grounds: one for the HV circuit and another one for the LV circuit. The HV ground should never come into contact with the chassis, whereas the LV ground is connected to the chassis, similar to a standard vehicle battery.

This configuration ensures that neither the rider nor anyone touching the vehicle will ever be exposed to the high-voltage system.

IMD (Insulation Monitoring Device)

Referring to the electrical diagram, we see an important component named IMD. This is an electric vehicle with both high-voltage and low-voltage systems, and one of them presents a potential safety hazard. An IMD (Insulation Monitoring Device) is required to monitor and protect against electrical faults.

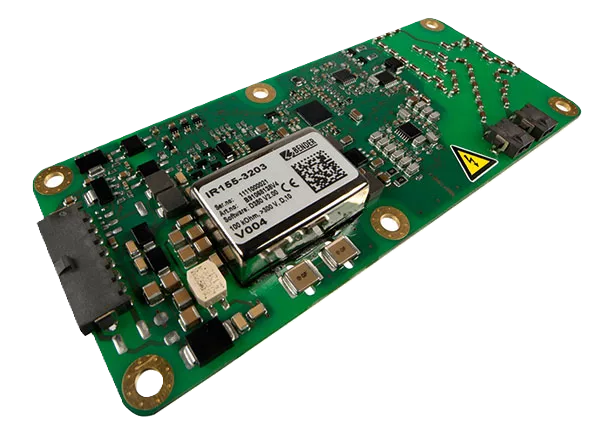

Organization’s IMD9

Organization’s IMD9

In simple terms, the IMD is similar to a differential circuit breaker in a traditional electrical installation. It’s connected to both, the HV and LV systems and can detect insulation faults between the two circuits, down to a resistance of 10 MΩ. This feature helps protect the rider or others from exposure to the HV circuit in the event of a fault.

The device setup is straightforward, as shown below:

IMD pinout9

IMD pinout9

- XLA-: Negative line of the HV system (0 to 1000V).

- XLA+: Positive line of the HV system.

- Pin 1: Supply ground.

- Pin 2: Supply positive (12V or 24V).

- Pin 3: Chassis ground.

- Pin 4: Additional chassis ground connection.

- Pins 5-7: Unused.

- Pin 8: Status output, activated when insulation is intact, enabling or disabling HV power via the SSRelay.

With this information we can start working on the security circuit.

Security circuit

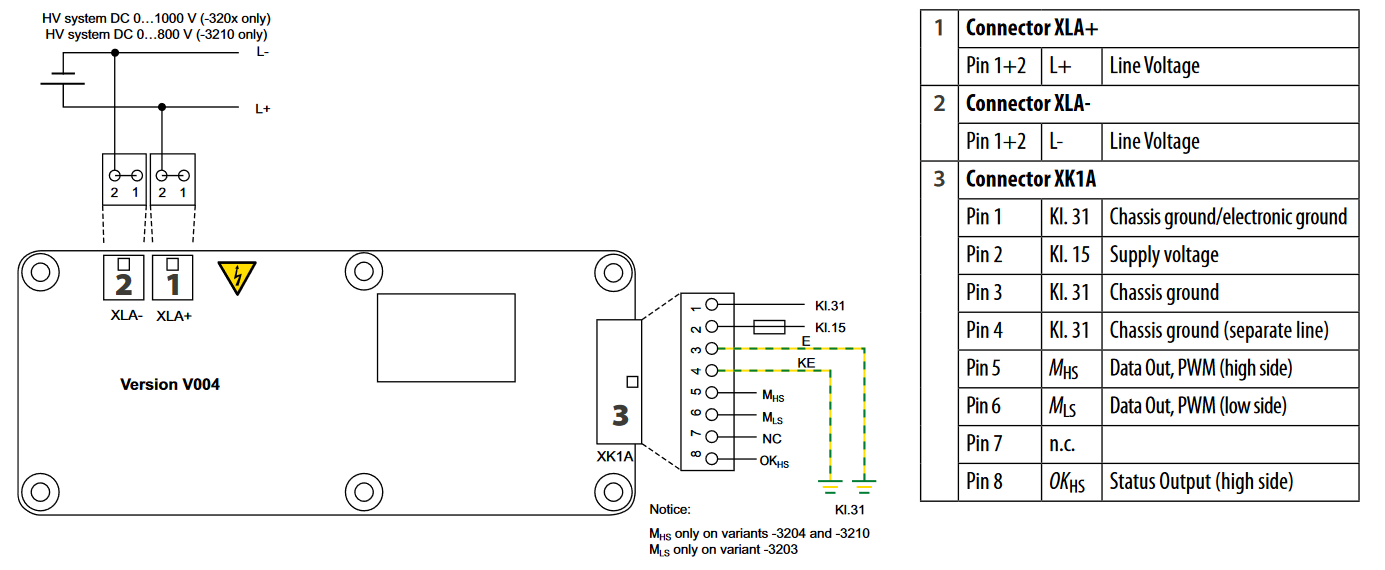

For the security circuit, the organization offer us two options:

Disconnection system with contactor directly controlled by the disconnection circuit:

Option 11

Option 11

This is not our case so I will skip it.

Disconnection system with contactor directly controlled by the controller:

Option 21

Option 21

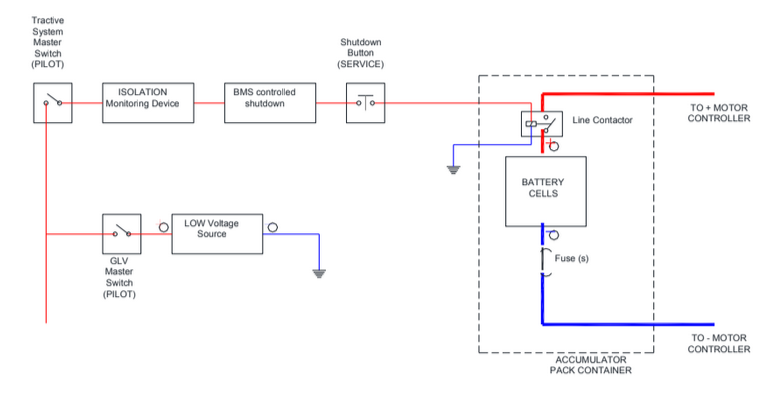

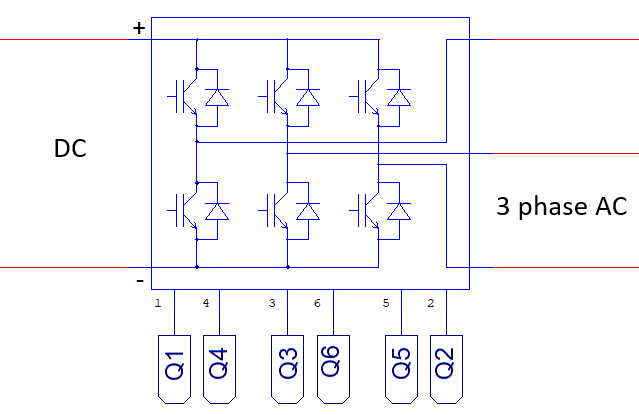

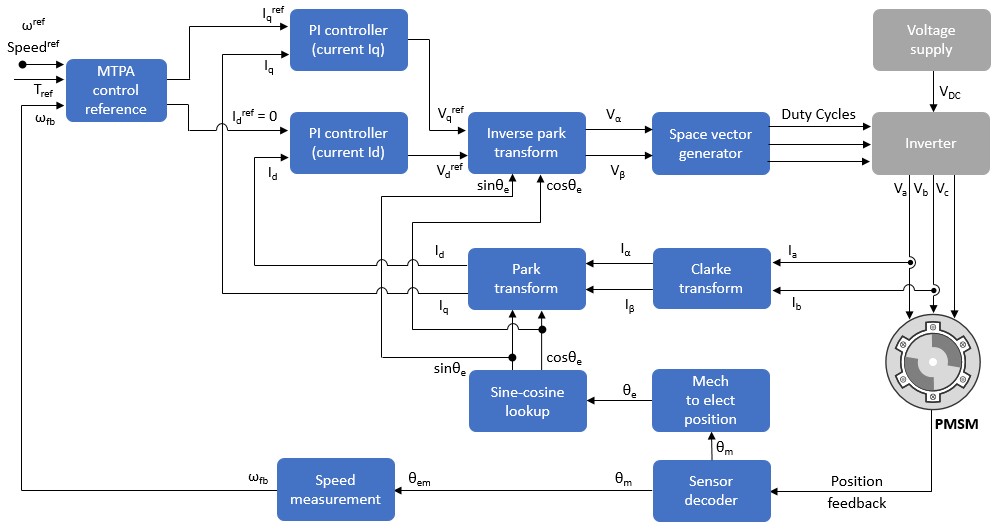

This is the schematic we will use. Let’s focus on the right side of the diagram where we have the battery pack with high-voltage (HV) positive (red) and negative (blue) lines. The positive power line includes a line contactor positioned between the inverter and the battery, controlled by the inverter via pink wires. When the inverter is ready, it activates the line contactor, closing it and supplying power to the inverter.

This process occurs when the SSRelay is closed. The inverter has two positive lines: one is the power line, as explained earlier, and the other, connected through the SSRelay, is for the logic supply. This line also carries high voltage but at a very low current (around 5A for our inverter). When the SSRelay is closed, electricity flows from the battery pack to the logic supply, starting the inverter. Once the inverter is ready, it enables the line contactor control, closing the line contactor and initiating the inverter’s traction power.

The SSRelay is controlled by a low-voltage signal (12V in our case), acting as an interface between the high and low voltage circuits. To open or close the HV circuit, switches can be placed in series with the SSRelay control. If any of these switches are opened, the HV circuit will also open. For example, the IMD is connected in series with the SSRelay, so if there is an insulation issue between the HV and LV systems, the SSRelay will disconnect power from the inverter, causing the main contactor to open as well.

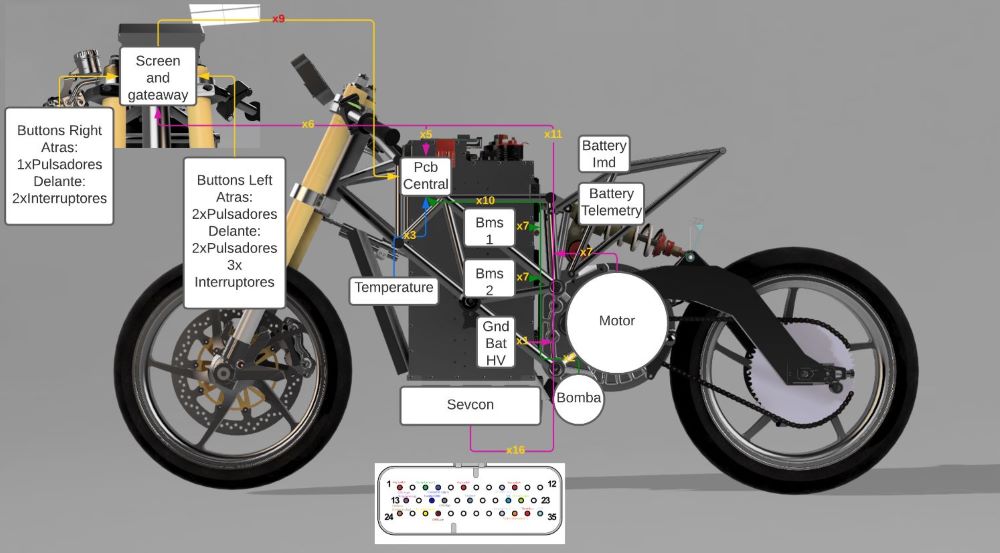

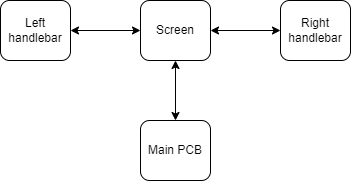

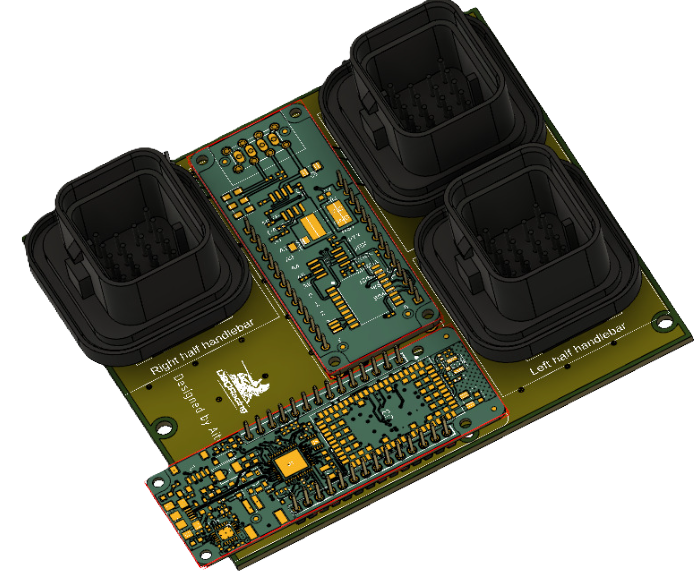

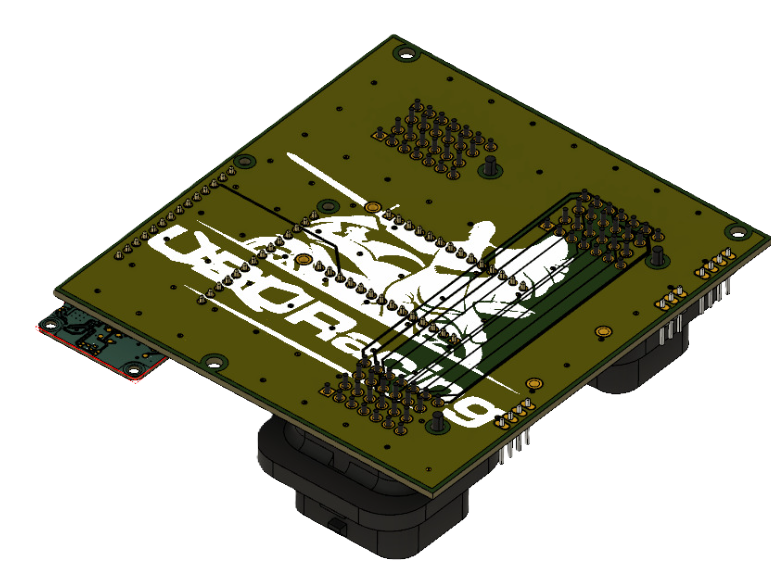

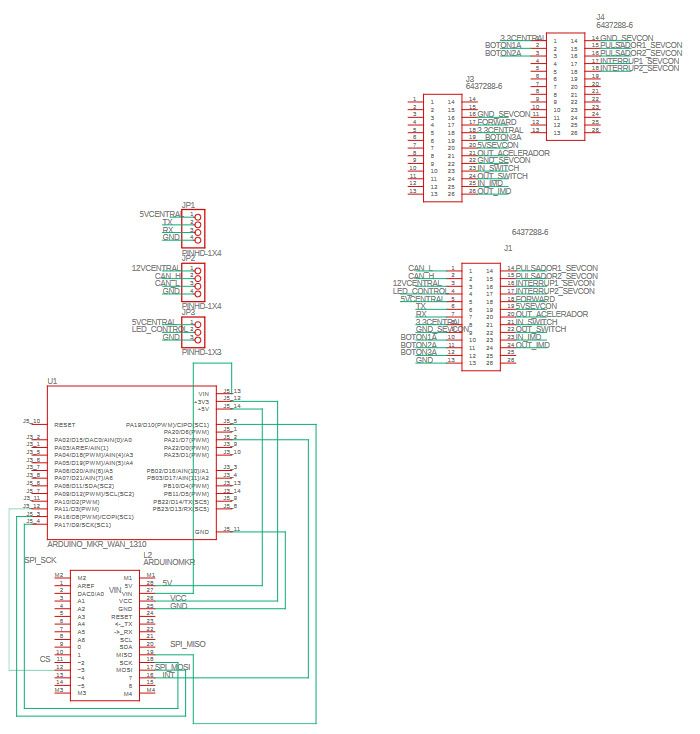

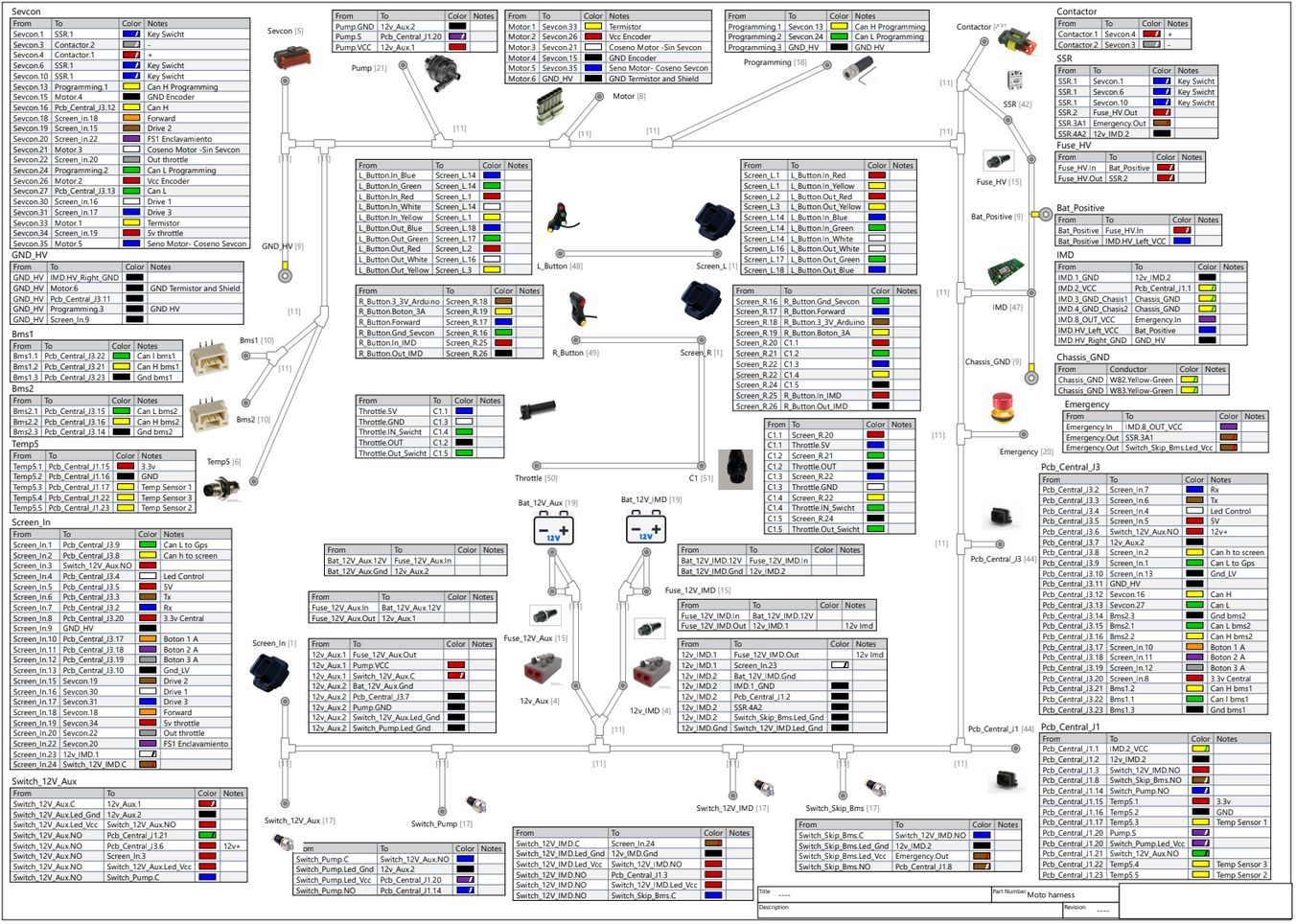

Wiring architecture

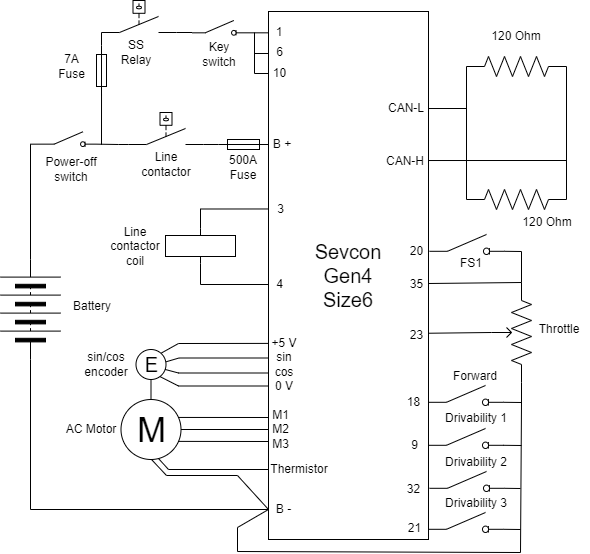

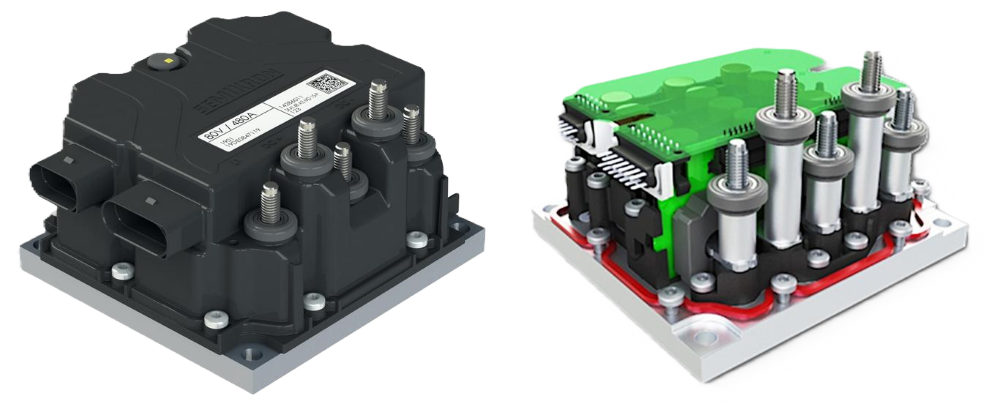

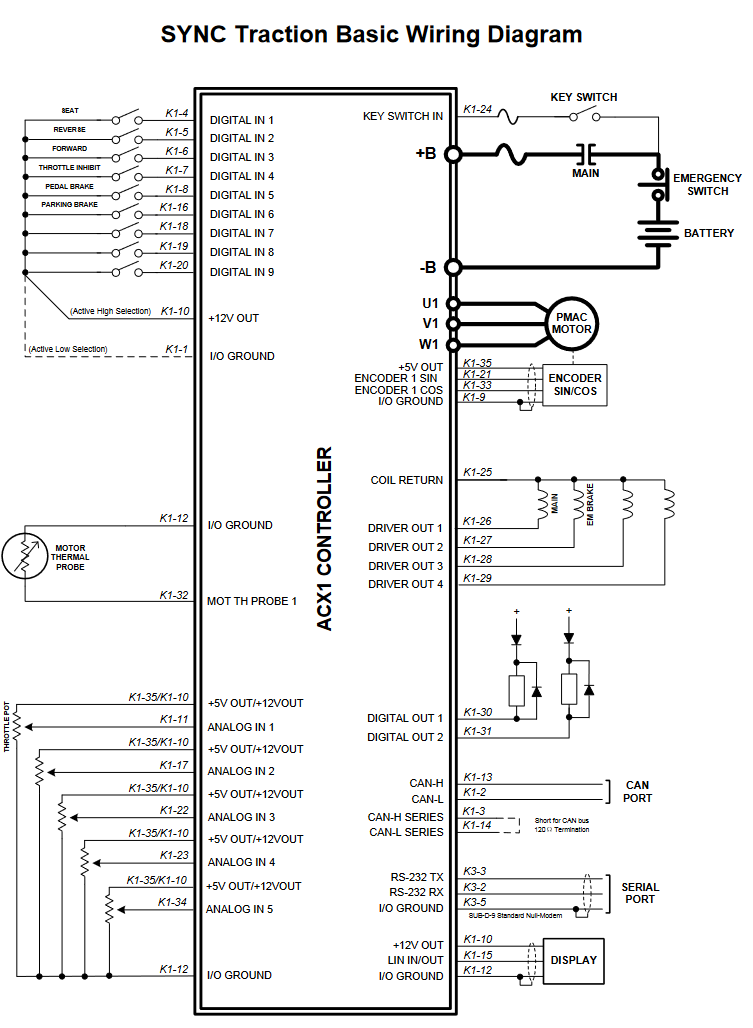

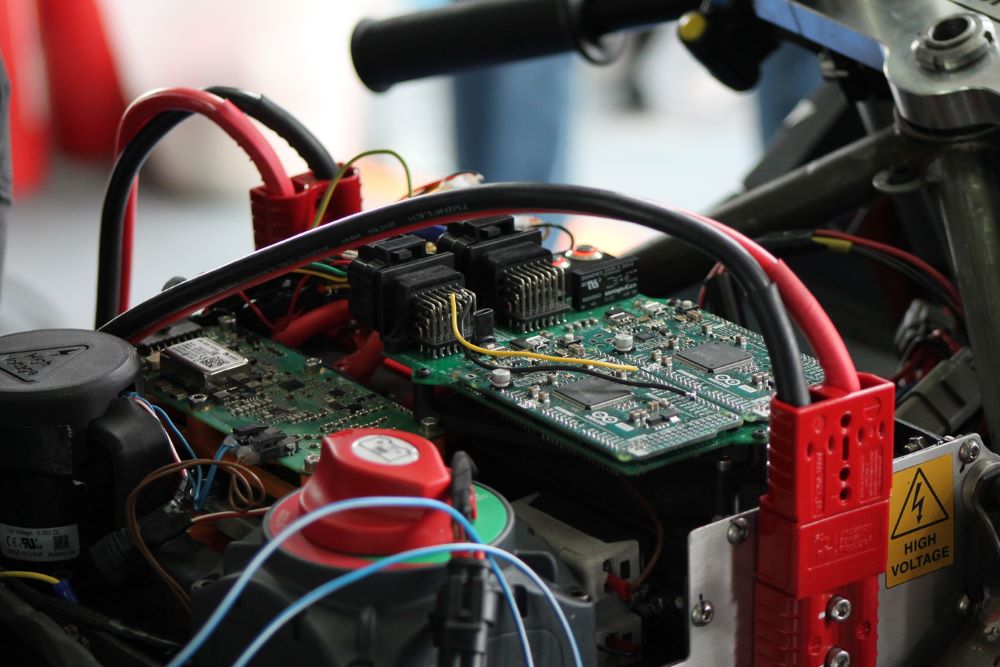

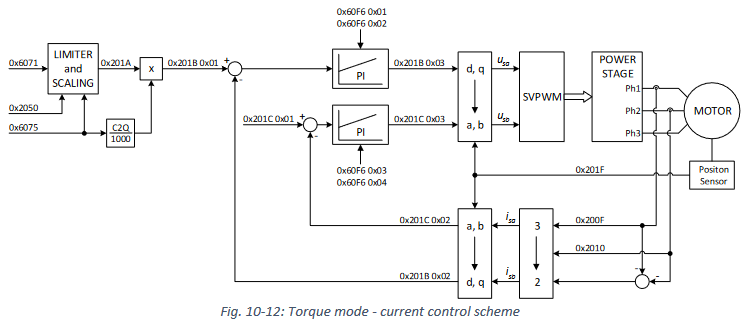

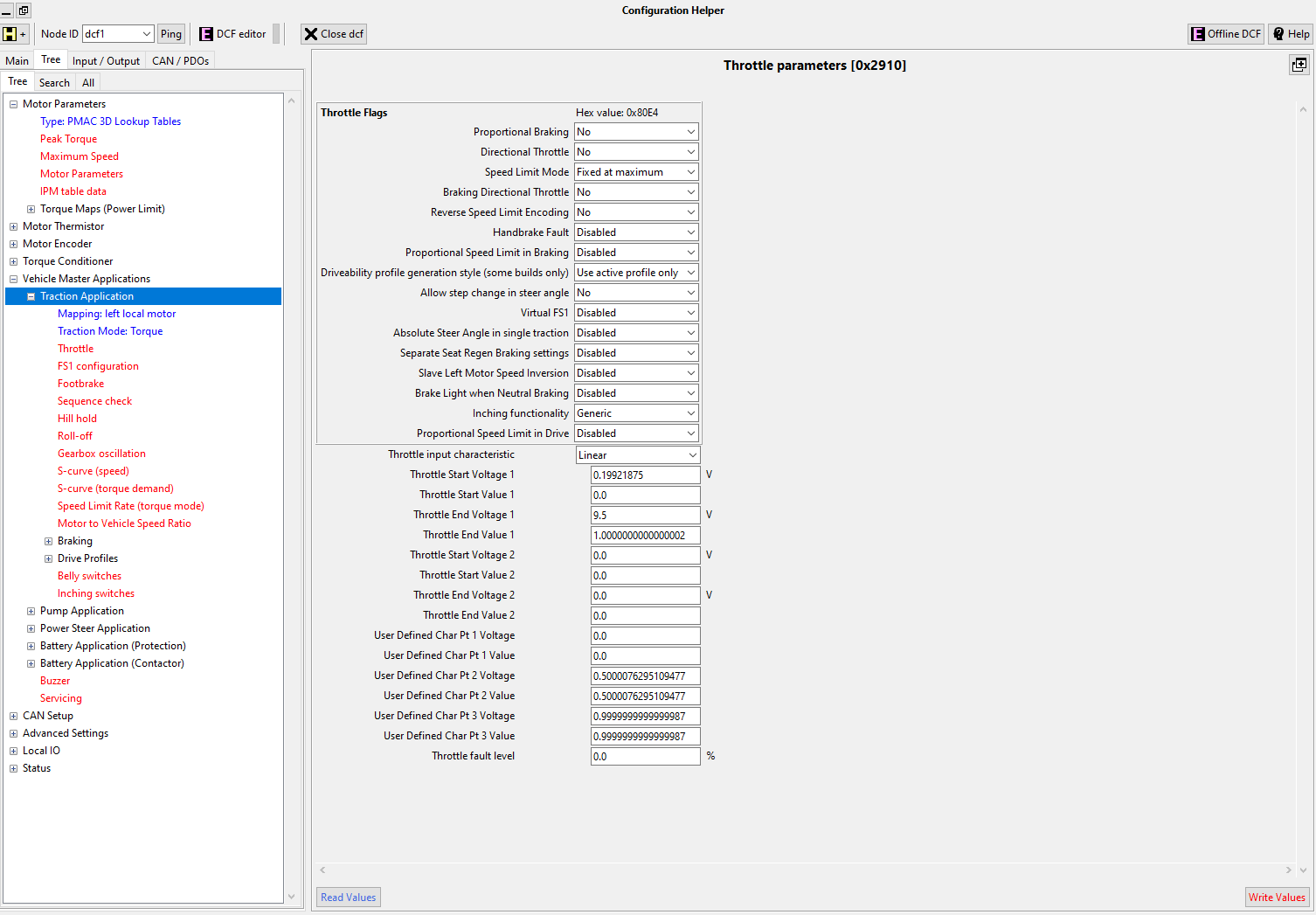

With the security system in place, we could begin working on the high-voltage (HV) system. Using the service manual for the Sevcon Gen4 Size6 inverter, we started designing the electrical scheme.

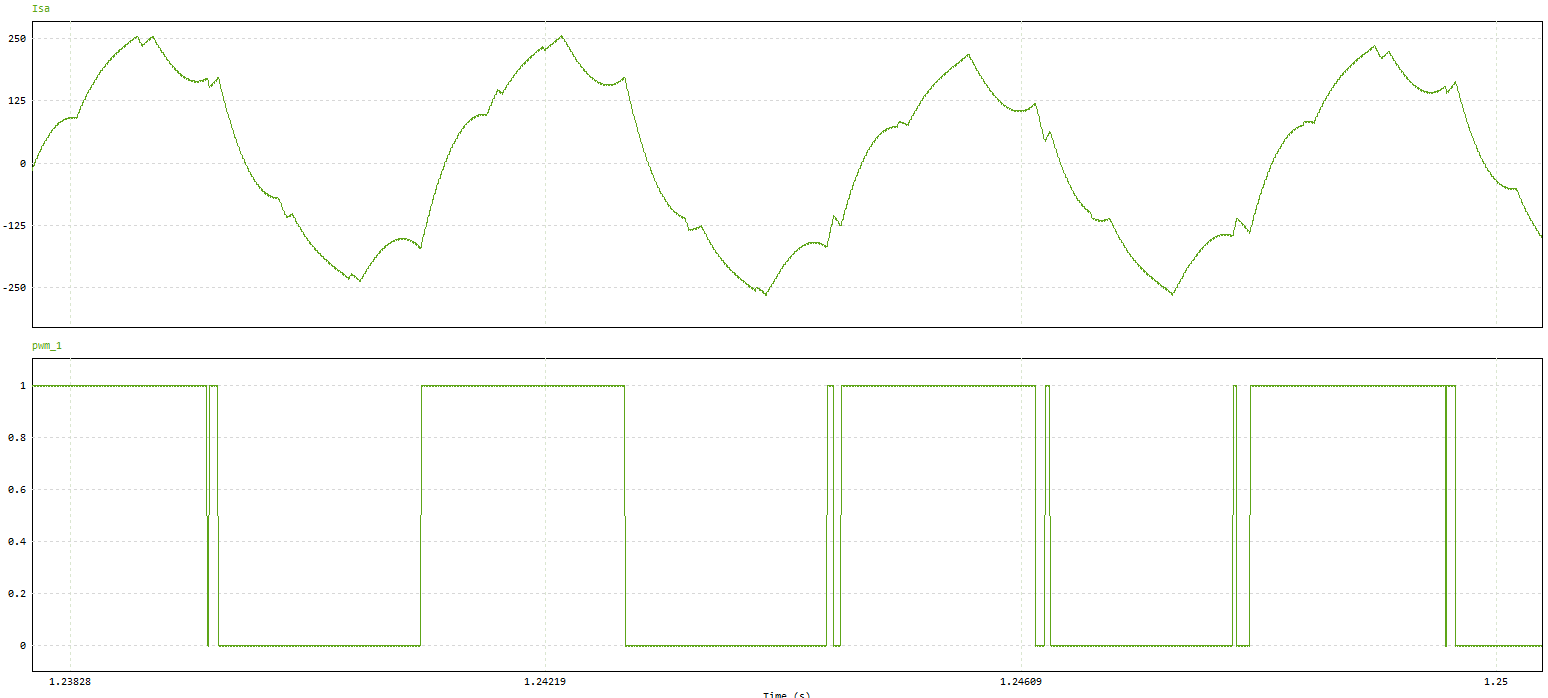

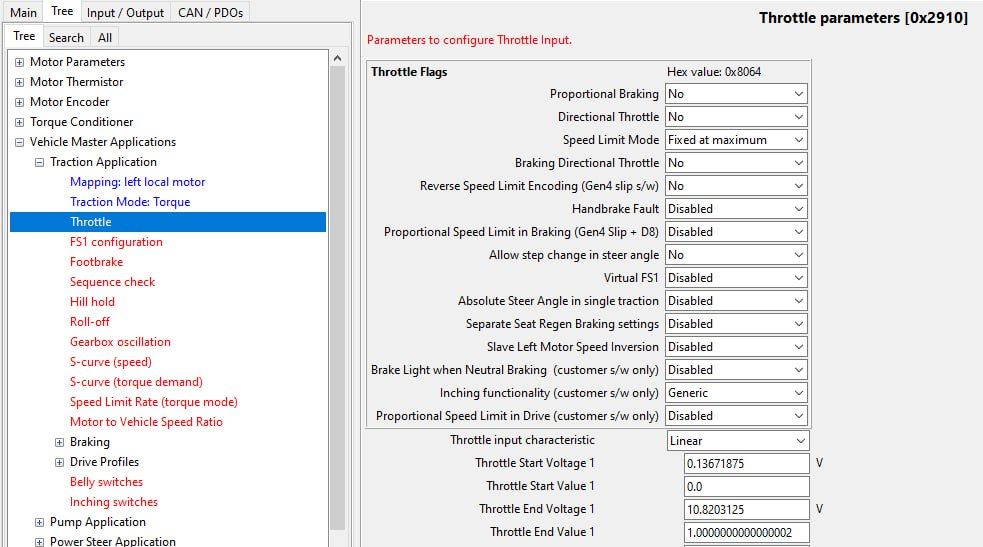

Inverter scheme

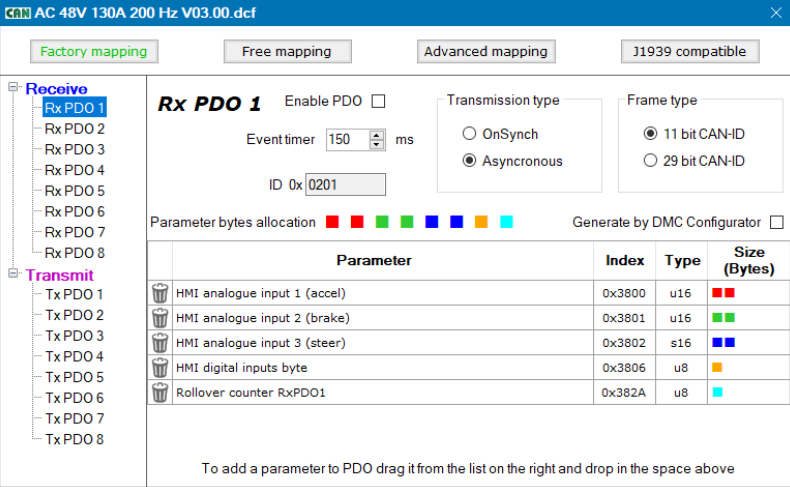

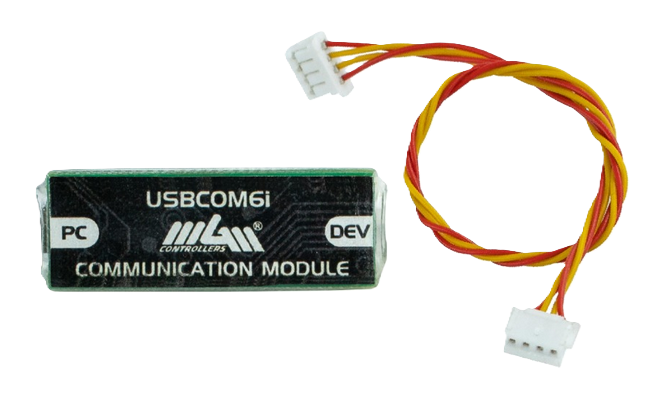

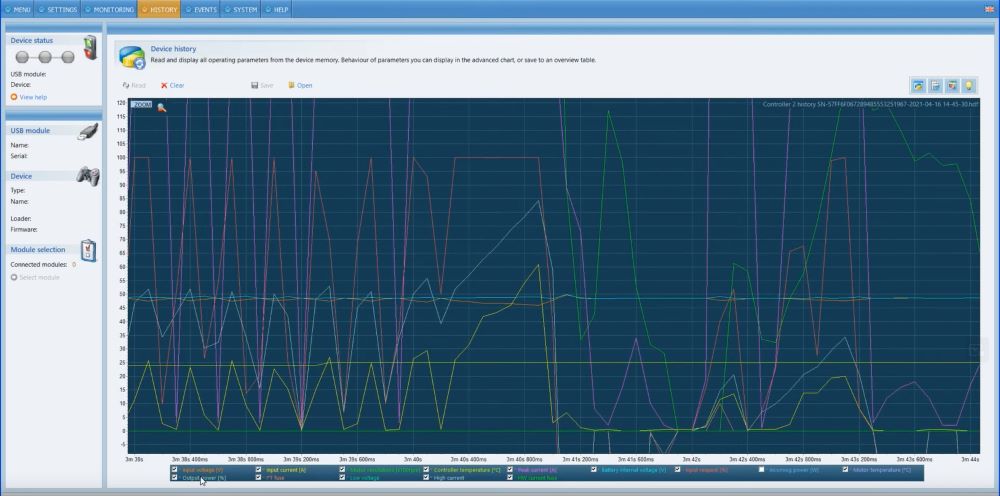

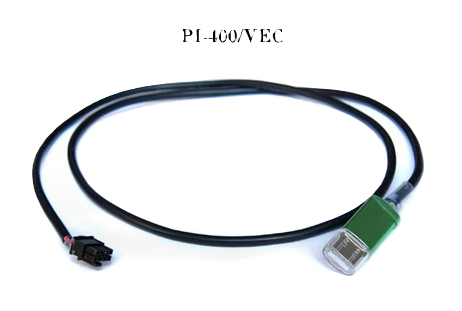

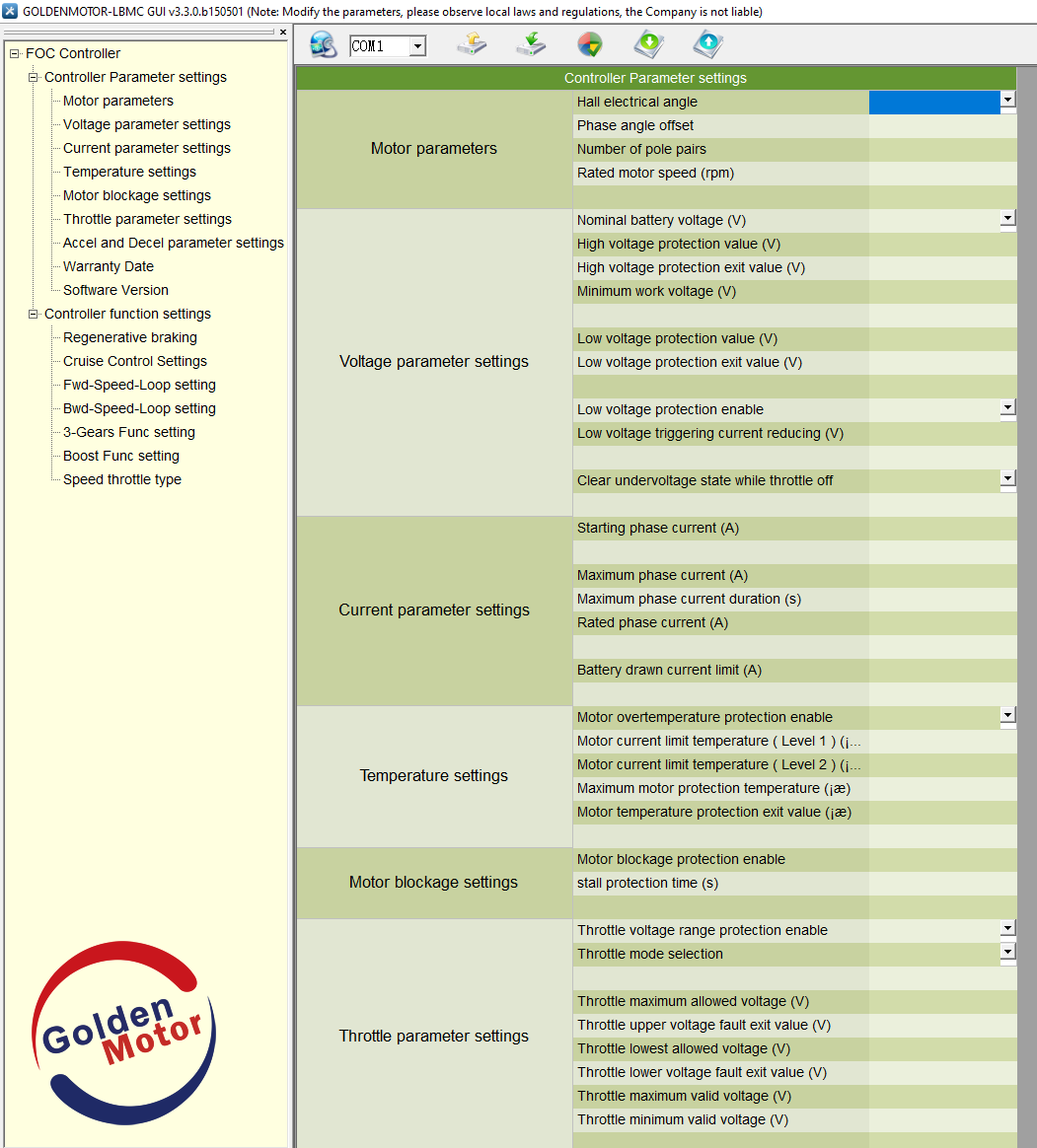

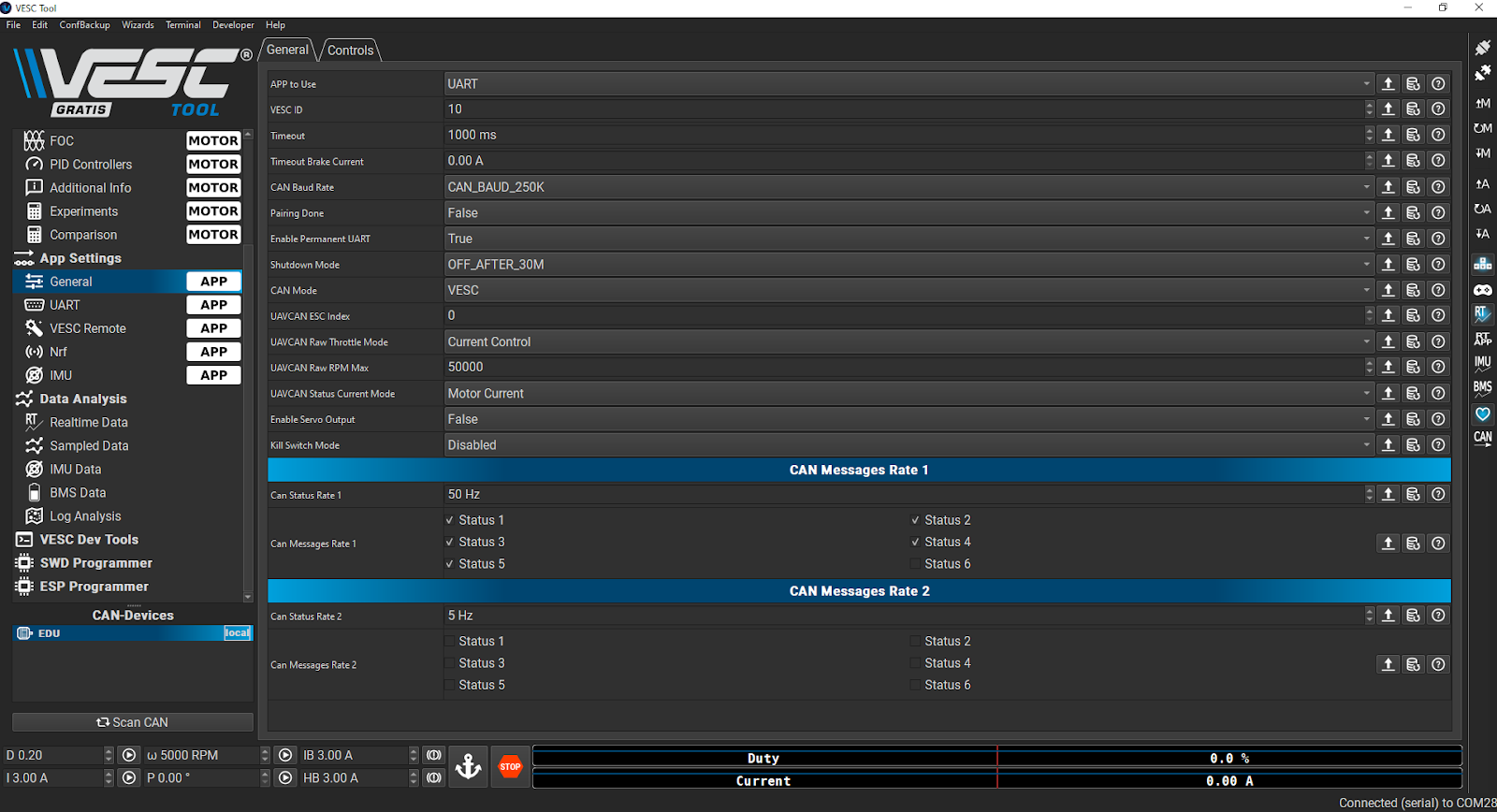

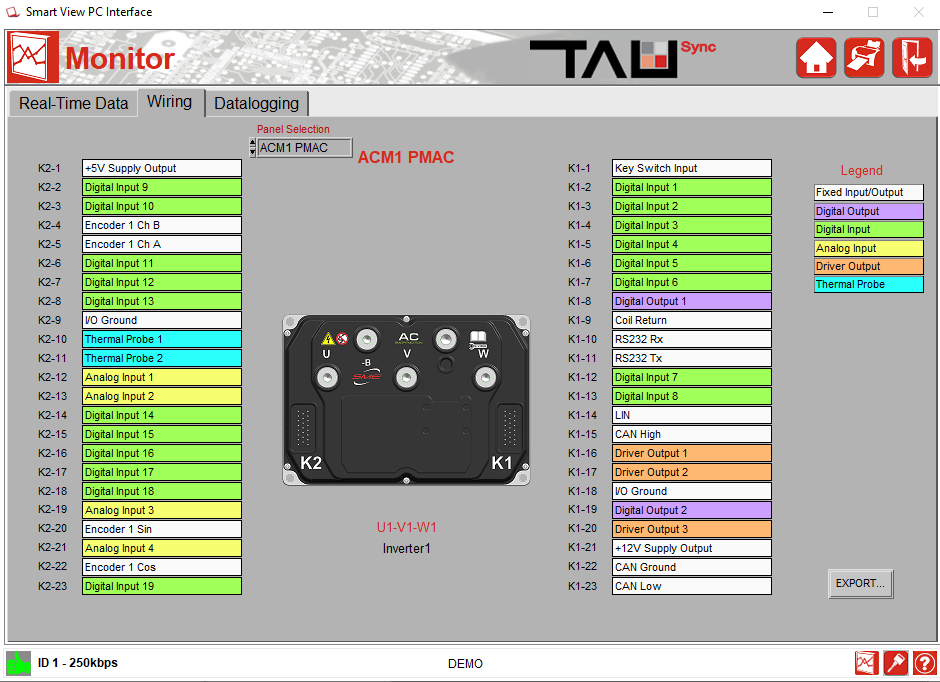

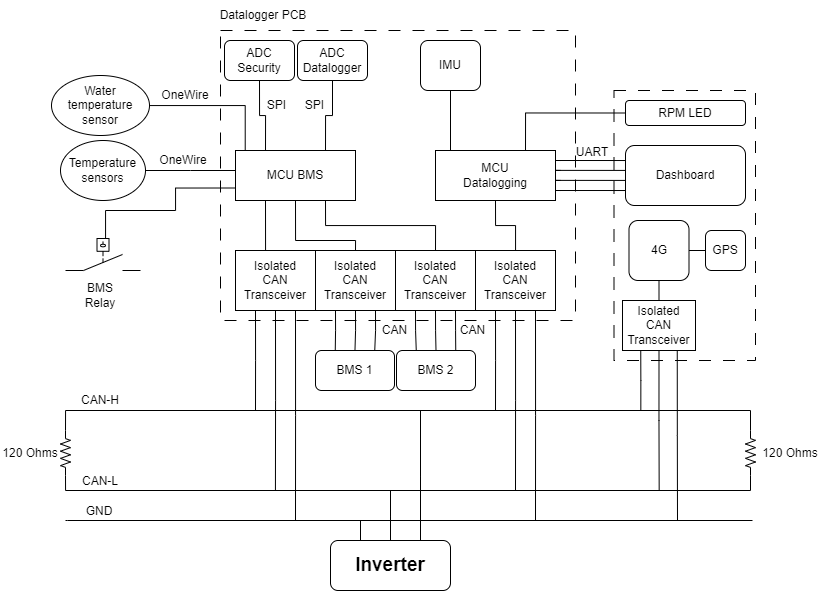

As we can see, it’s a simple schematic. Starting clockwise, we find two CAN-bus pins. These pins are used for the programming port and for monitoring. We created a CAN-bus network to collect all the data with our data logger, as I will explain later.

Next is the throttle input, which has a switch that activates or deactivates in the resting position for safety. The inverter can be configured with this switch as FS1, meaning it will not read the throttle potentiometer signal unless the switch is closed, preventing unintended acceleration.

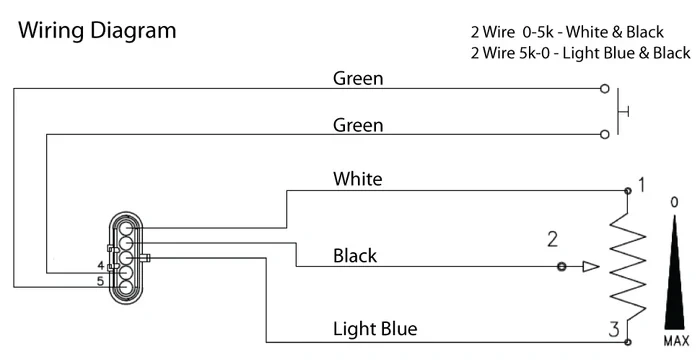

Following that is the potentiometer, which ranges from 0 to 5k ohms. It has a positive input, a signal input, and a ground, which is shared with the battery’s negative terminal (B-).

Lastly, there are several switches. The “Forward” switch must be closed to enable the vehicle to start moving. The “Drivability 1, 2, and 3” switches allow for different maps and characteristics to be set, such as limiting speed or reducing power as requested.

Domino twist grip throttle wiring diagram10

Domino twist grip throttle wiring diagram10

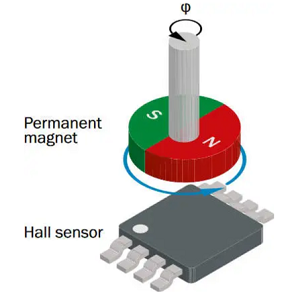

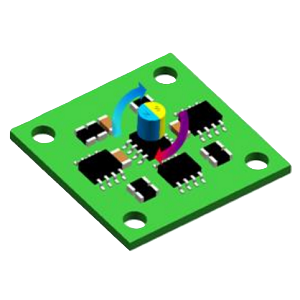

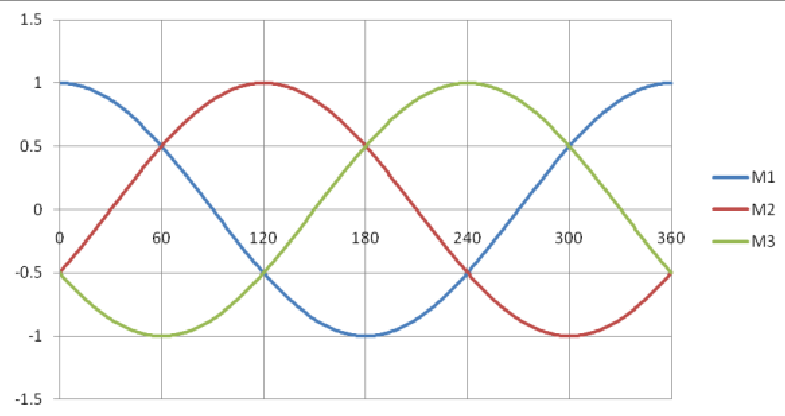

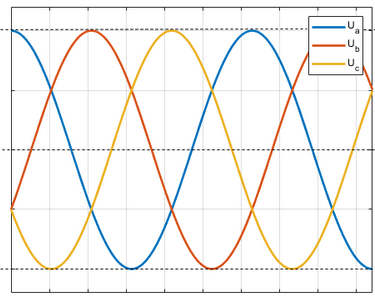

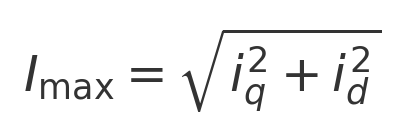

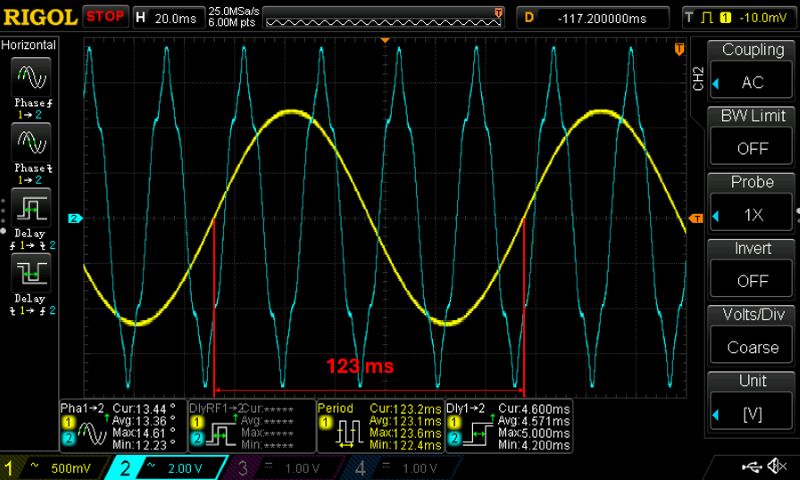

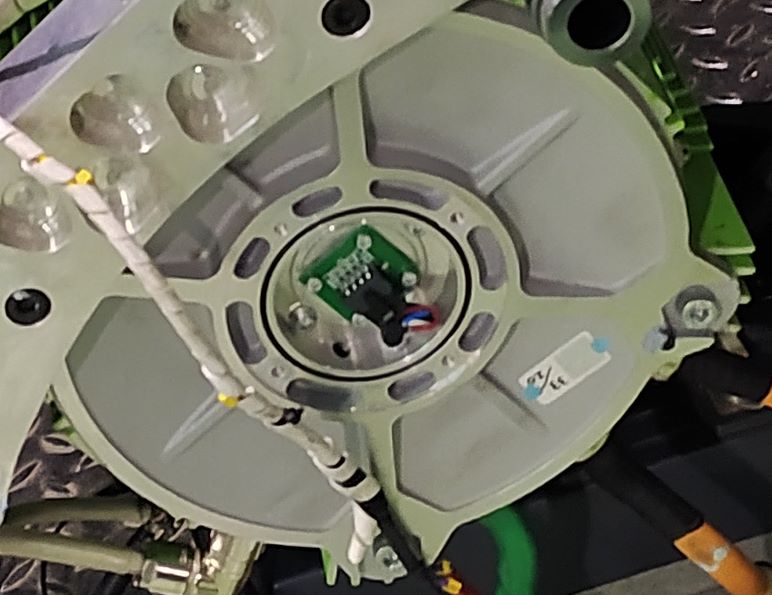

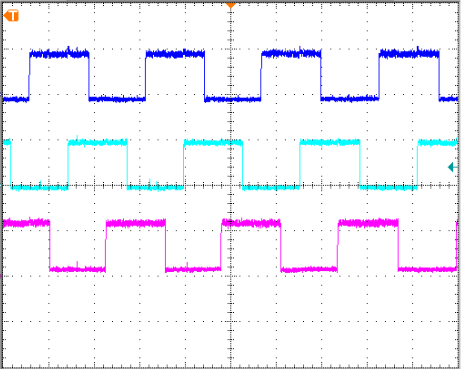

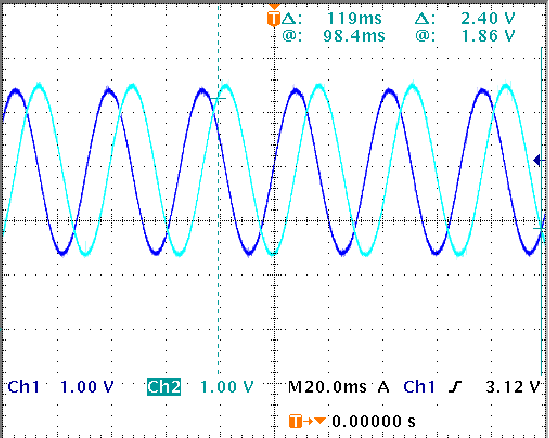

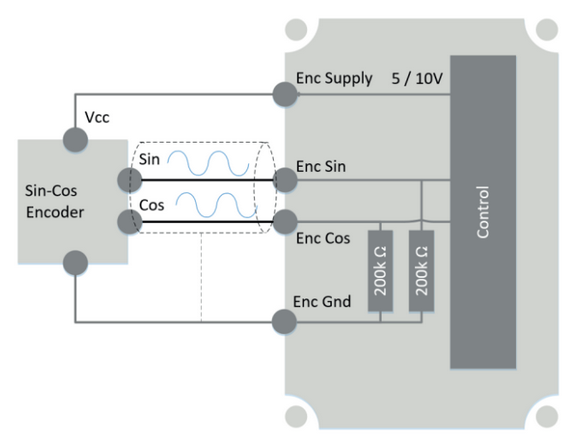

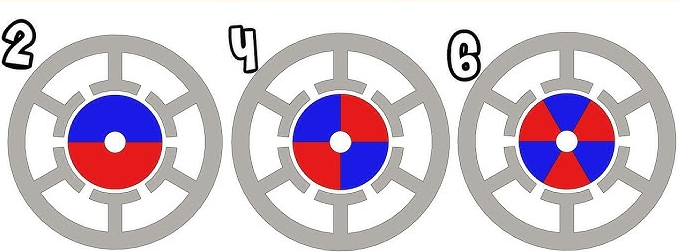

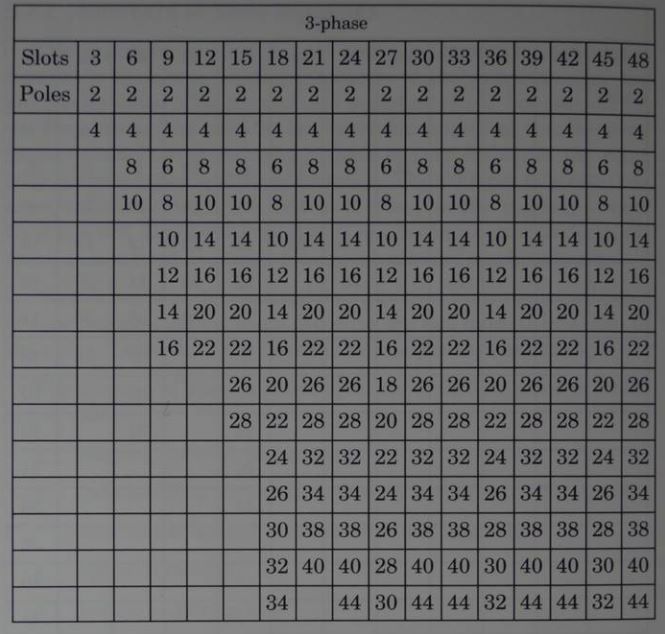

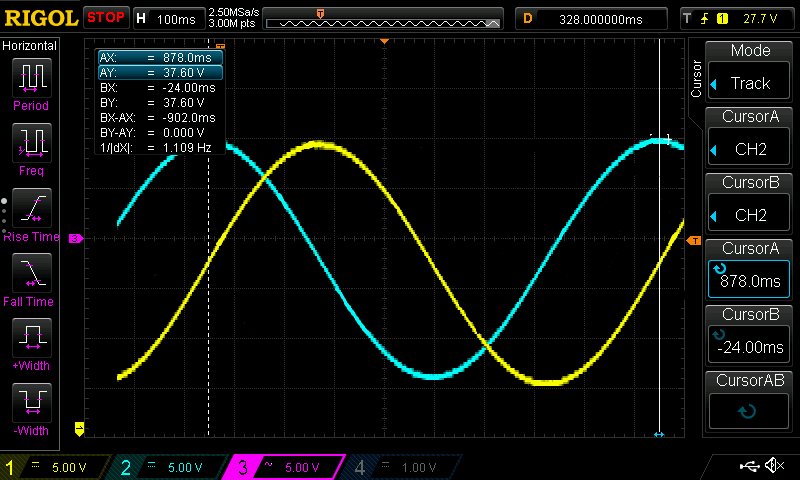

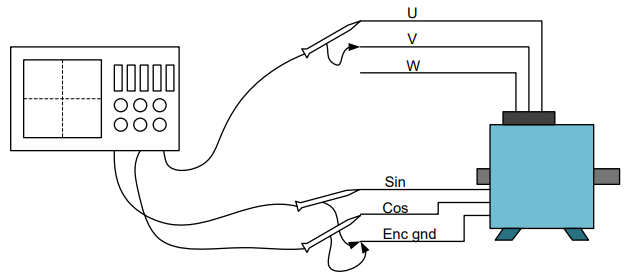

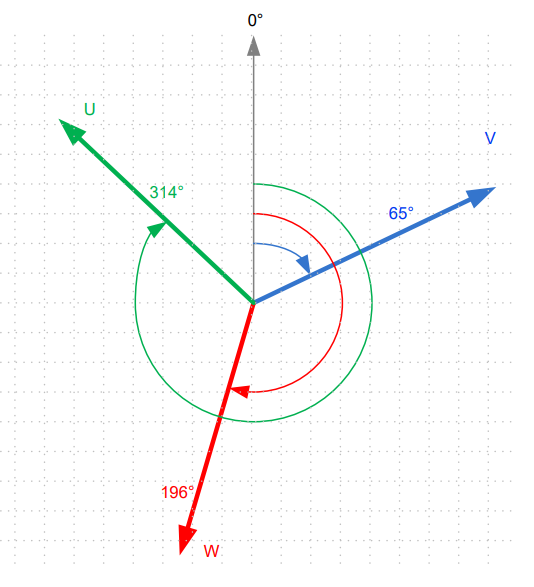

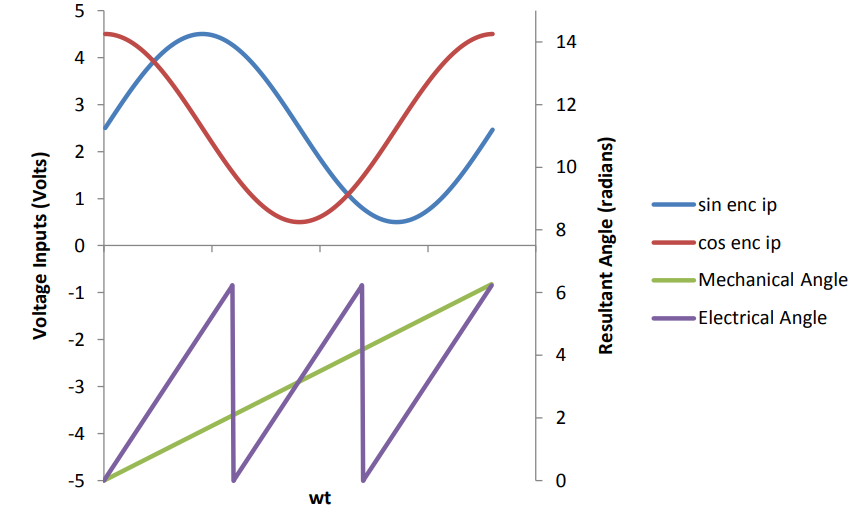

After that, we can see the electric motor. It has three power cables and another connector, typically for the thermistor, which measures the motor’s temperature, as well as the encoder signal. The encoder has four wires: positive, ground (different from B- and isolated), and the sine and cosine pins. This setup allows the inverter to determine the rotor’s position.

Next, there is the line contactor coil. This is driven by the inverter. When everything is ready, the contactor closes, and power is supplied to the inverter. In the middle of the line contactor, there is a manual disconnector that allows us to open the circuit even if the contactor remains closed for any reason, this is just for safety.

Finally, we have the key switch input. This inverter has three inputs for the same function because it has a high current consumption (a maximum of 7A), so we will connect all of them. In series, we have the SSRelay, which is driven by the LV circuit, as we will see later.

HV (High Voltage) scheme

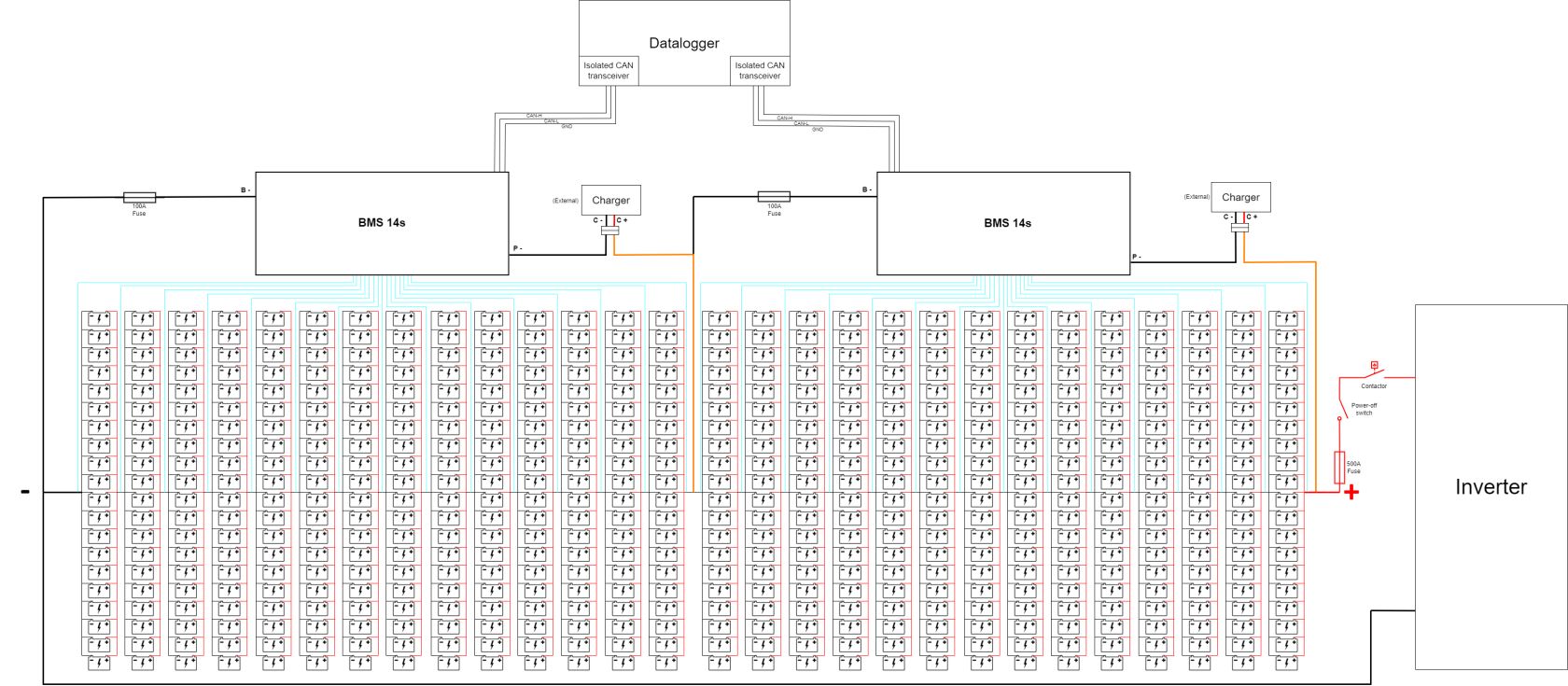

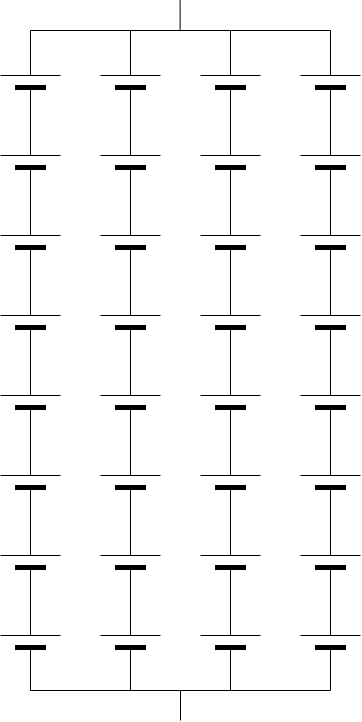

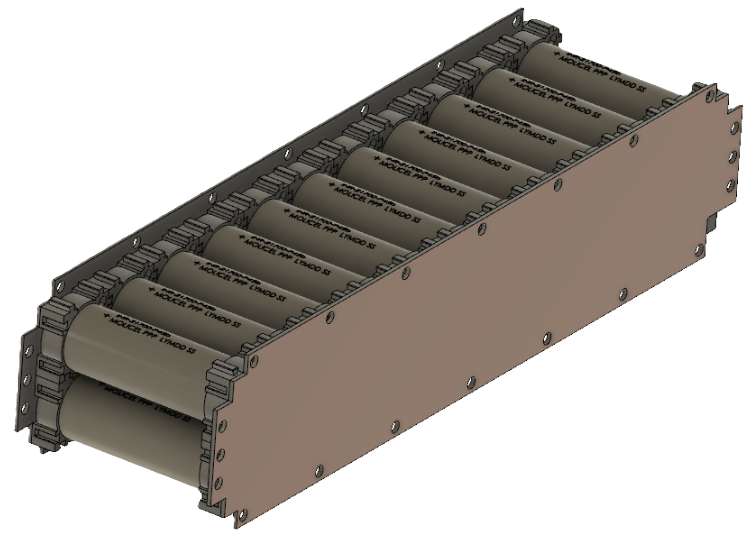

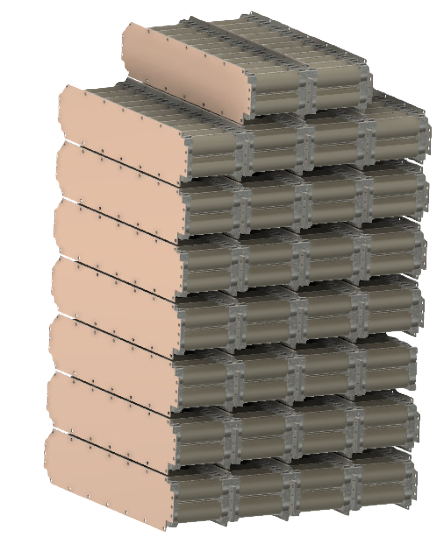

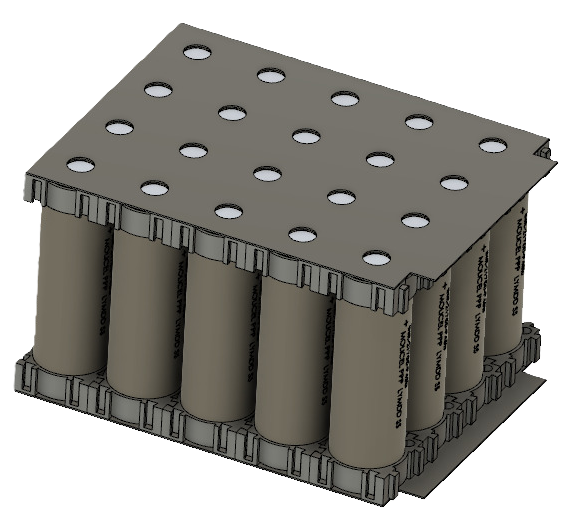

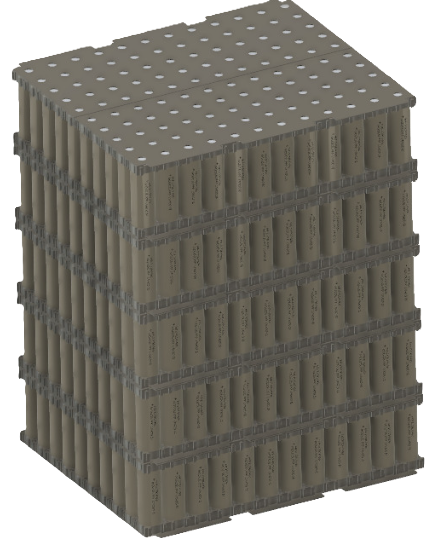

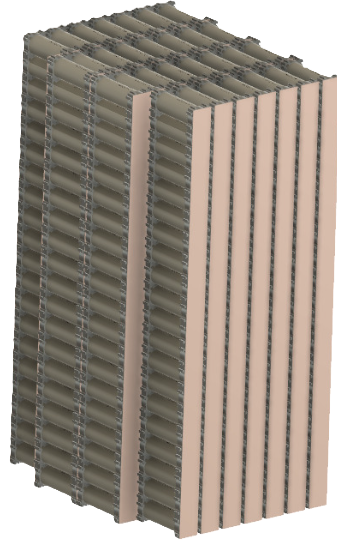

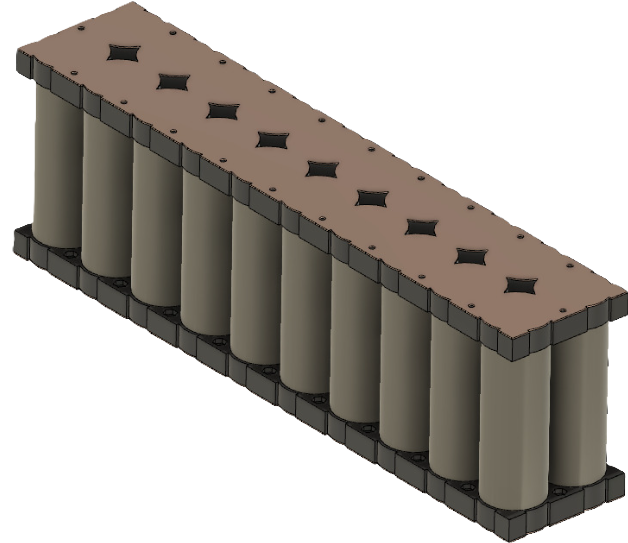

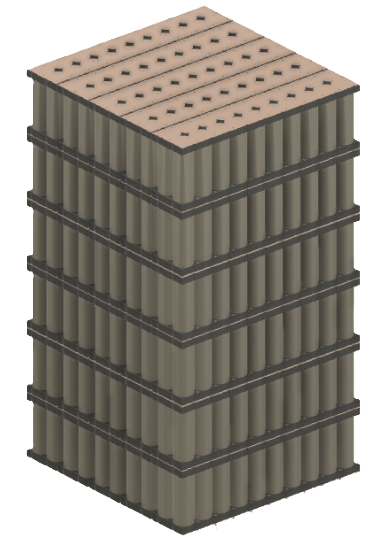

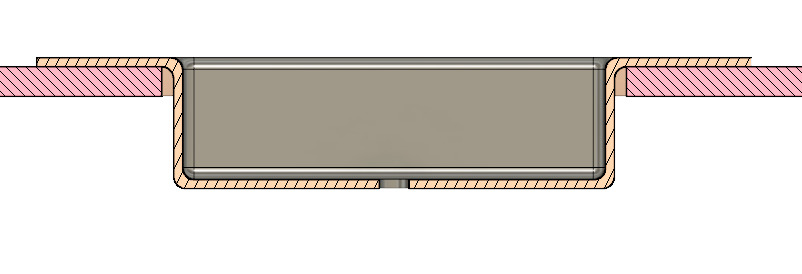

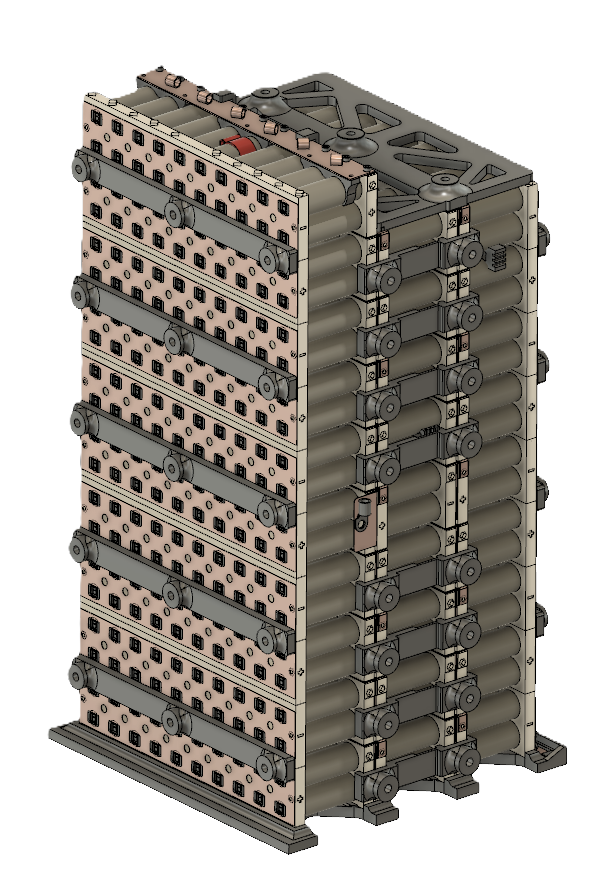

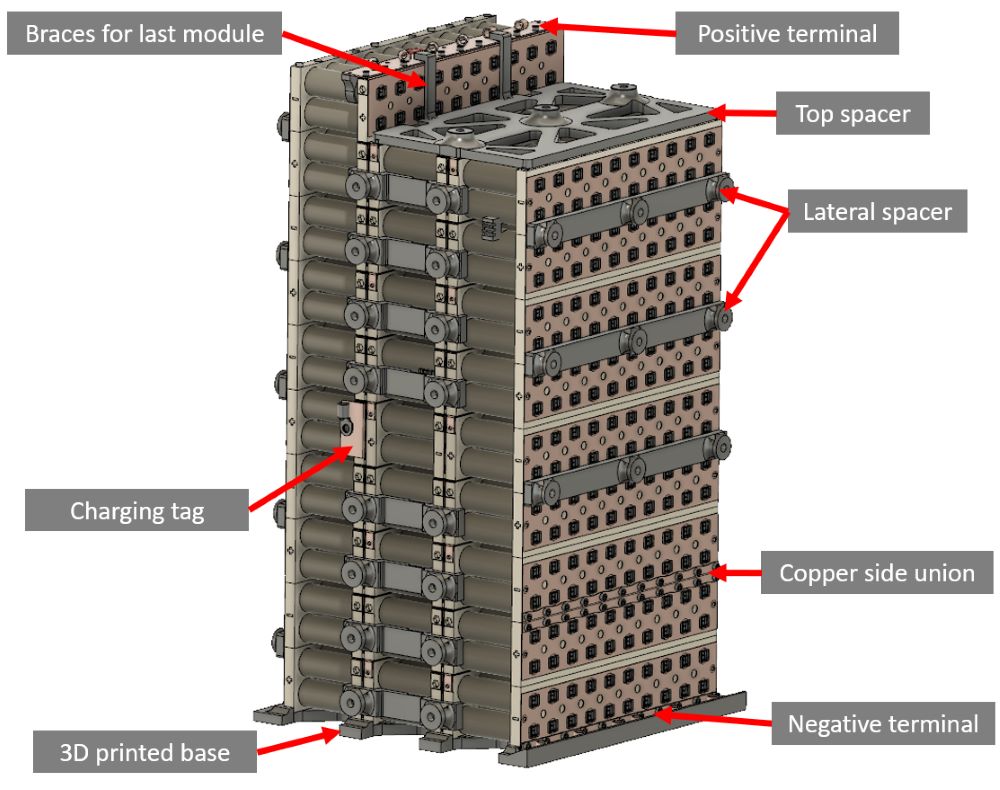

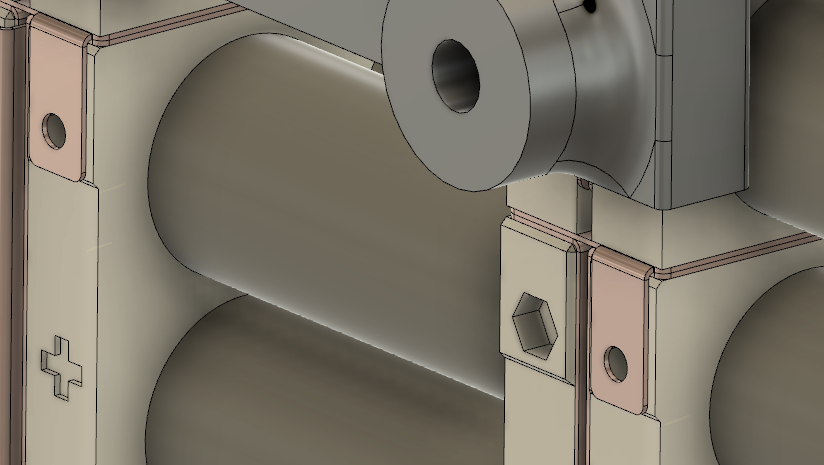

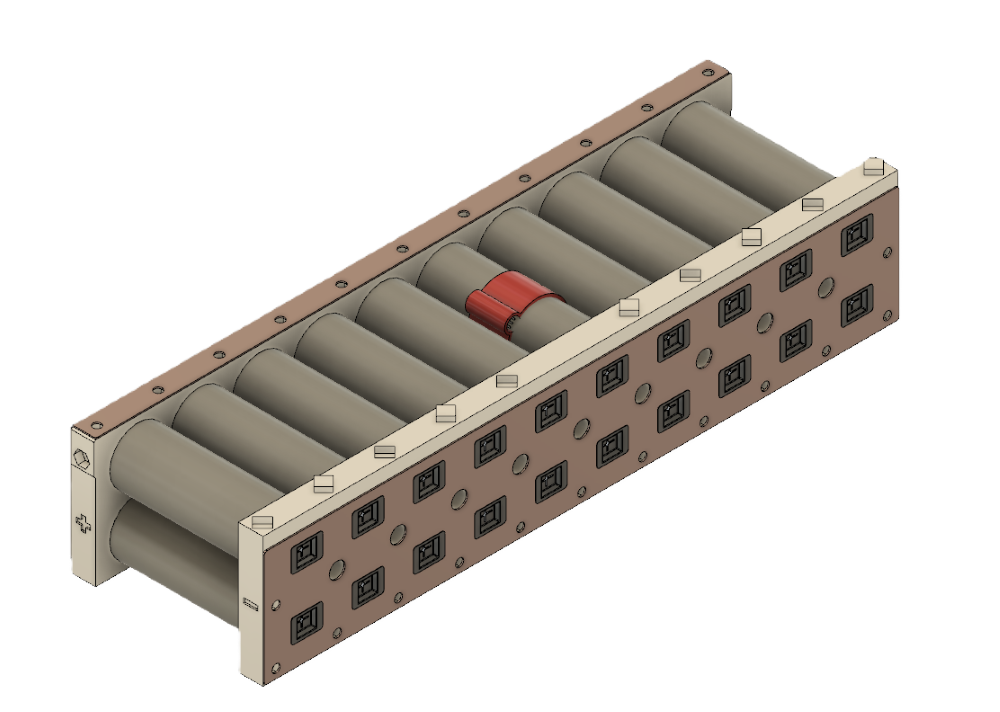

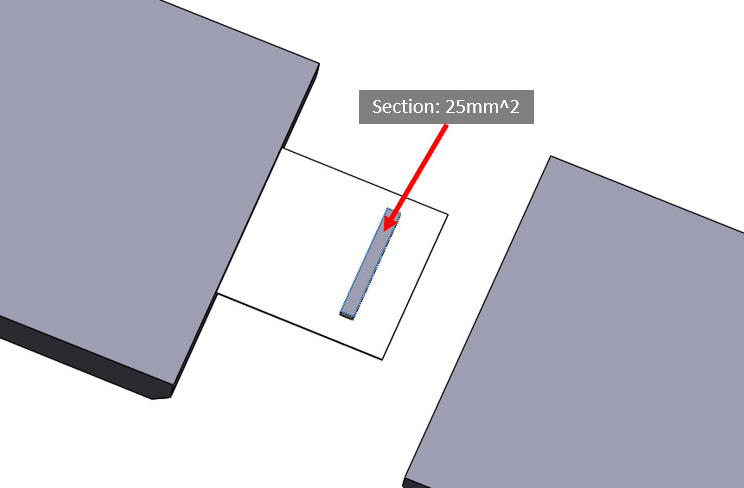

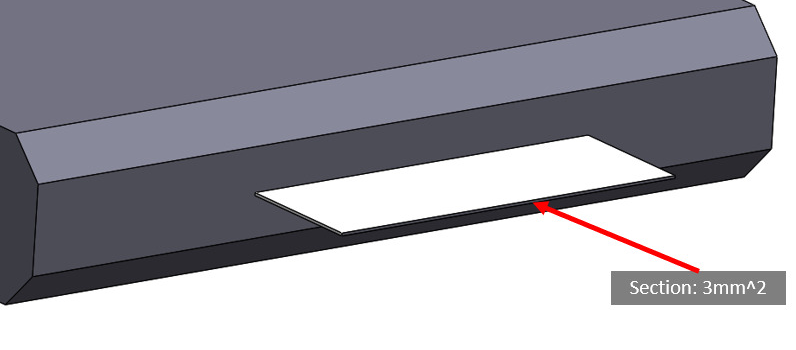

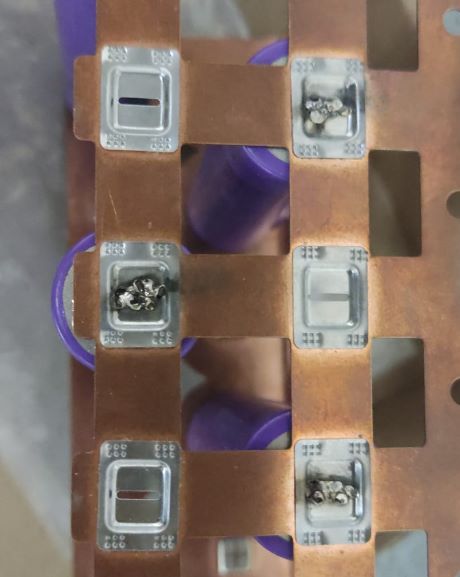

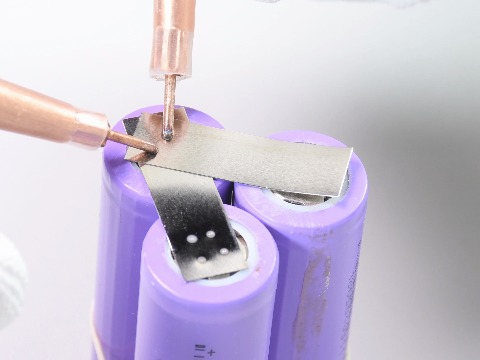

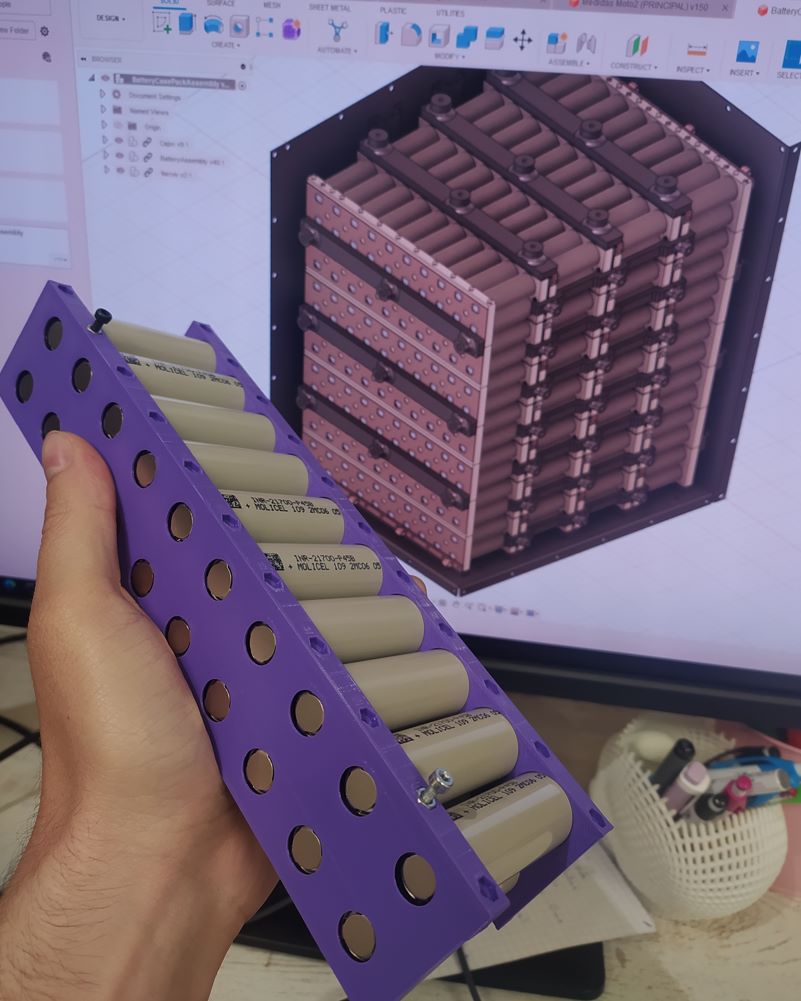

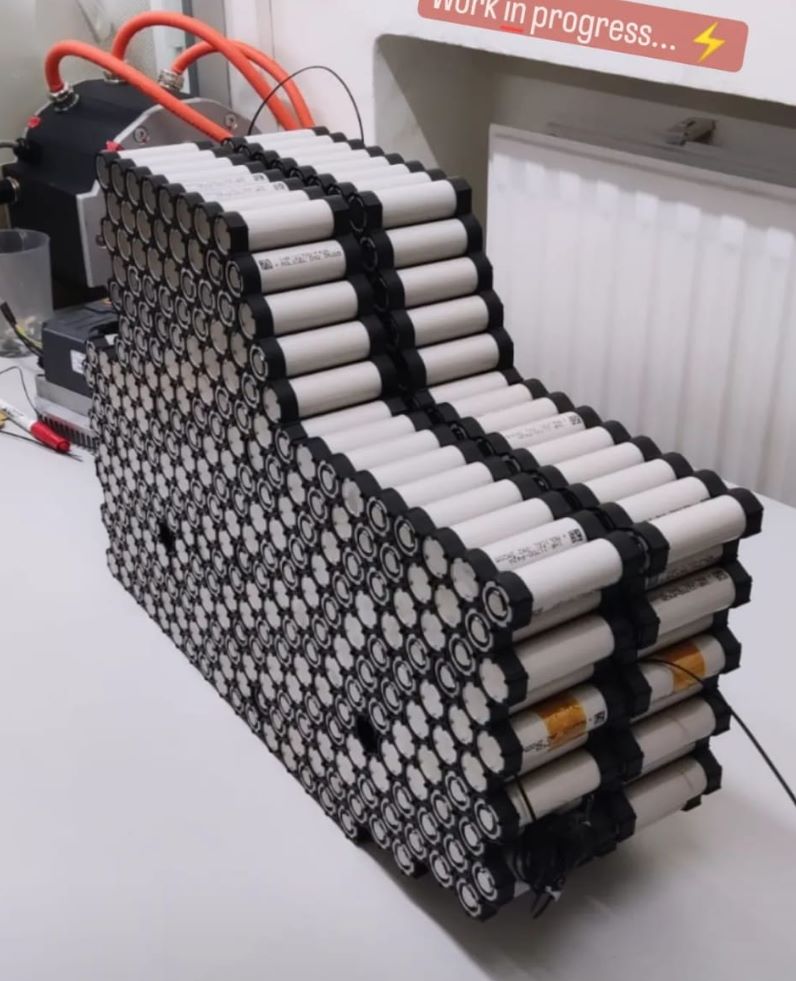

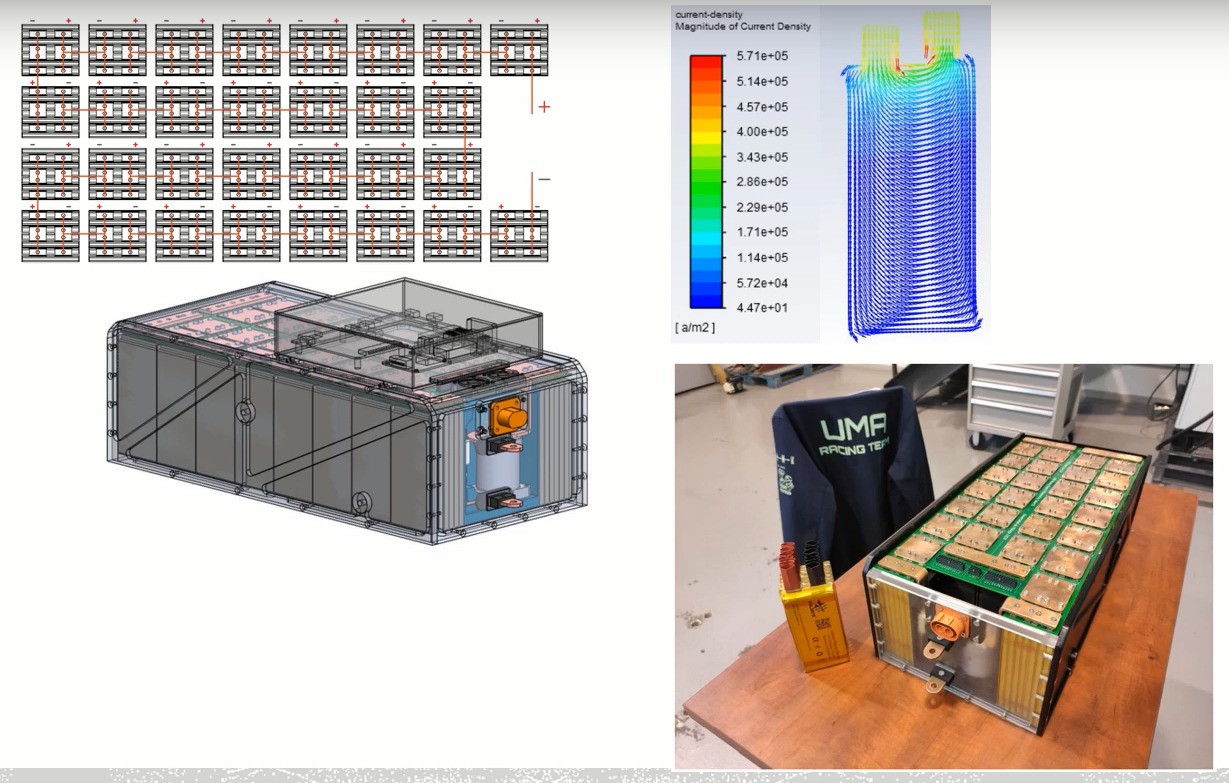

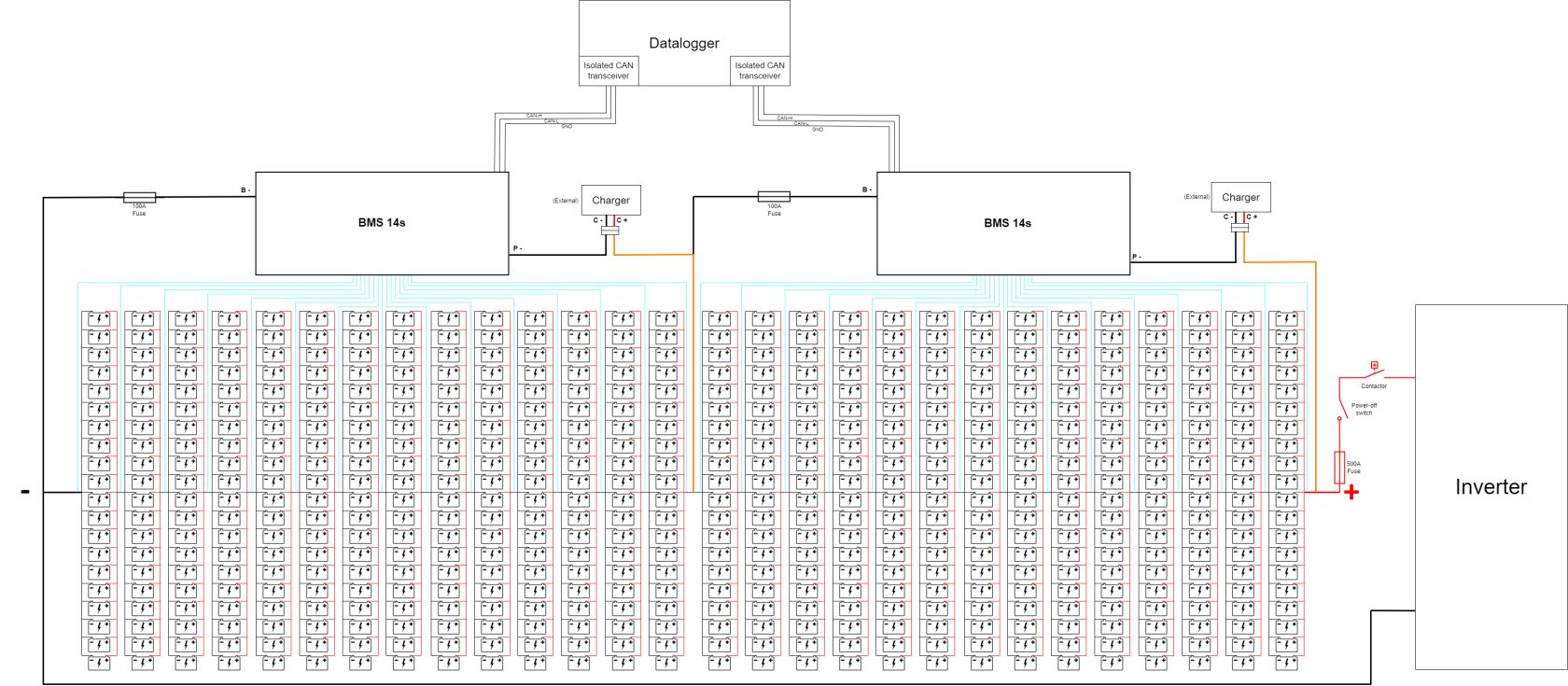

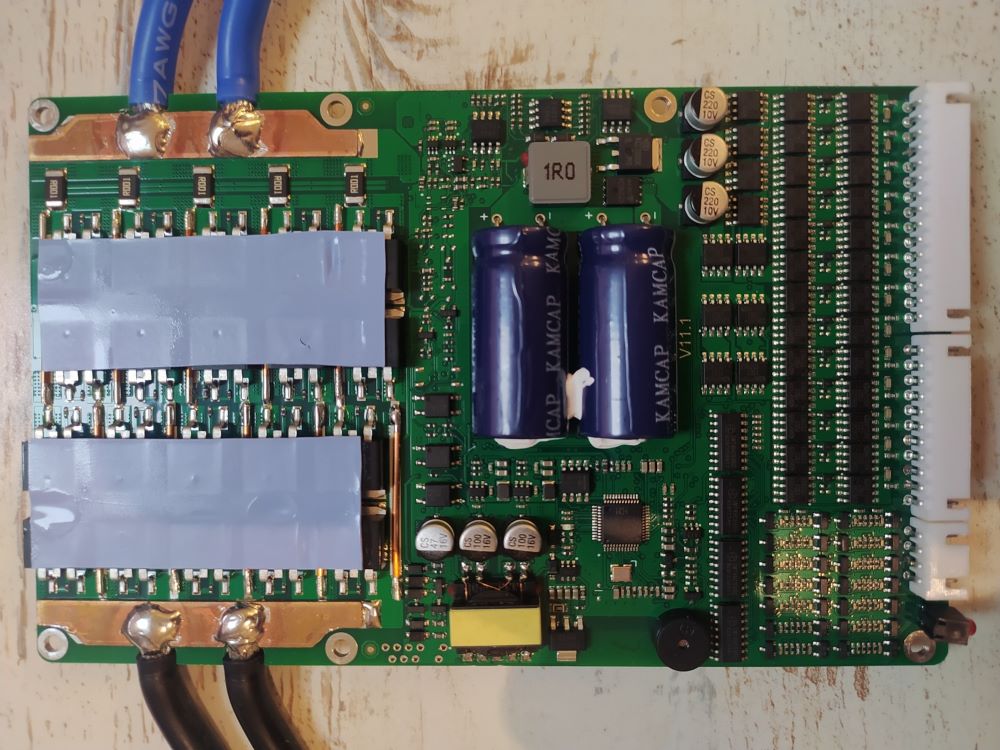

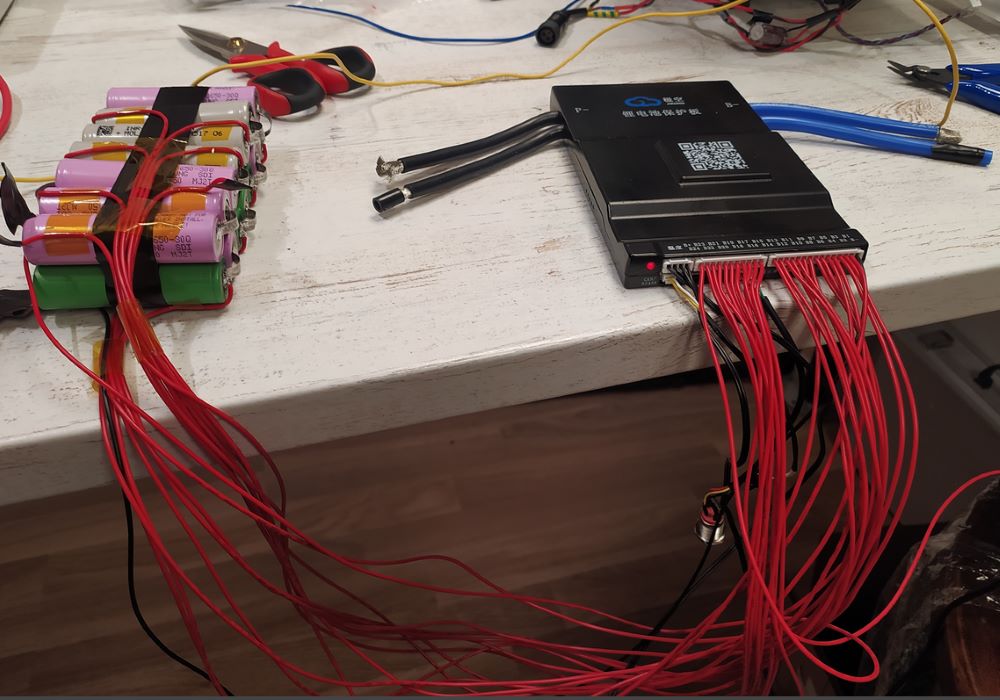

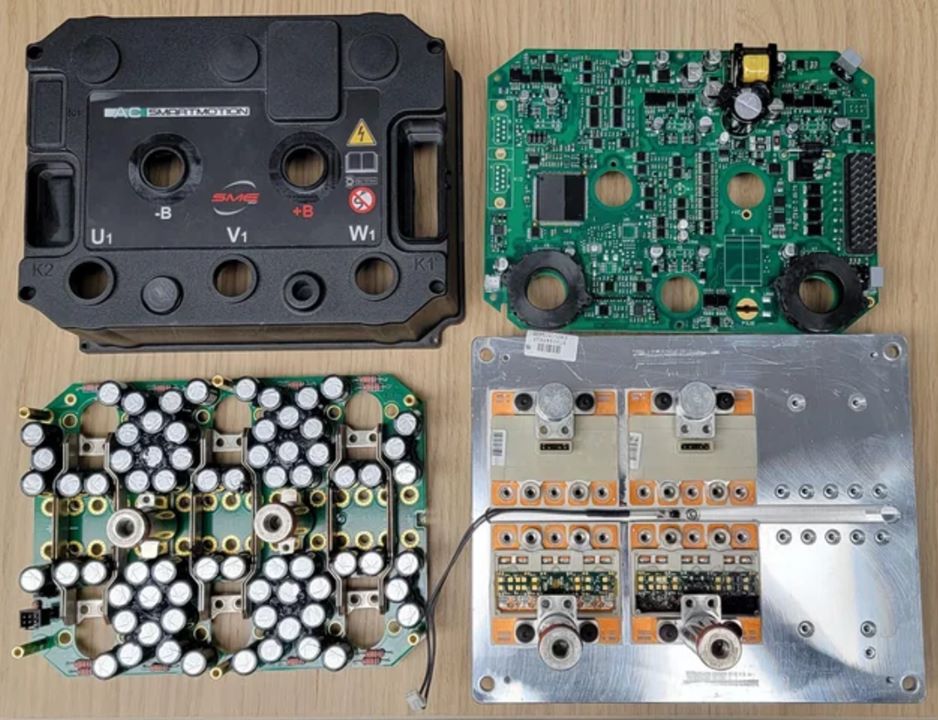

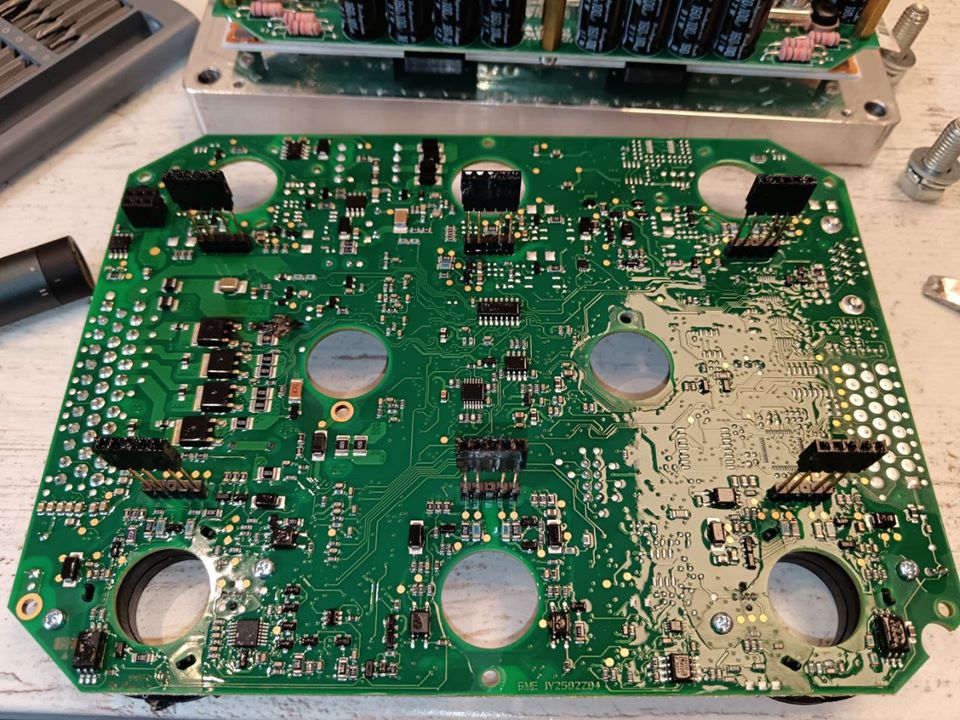

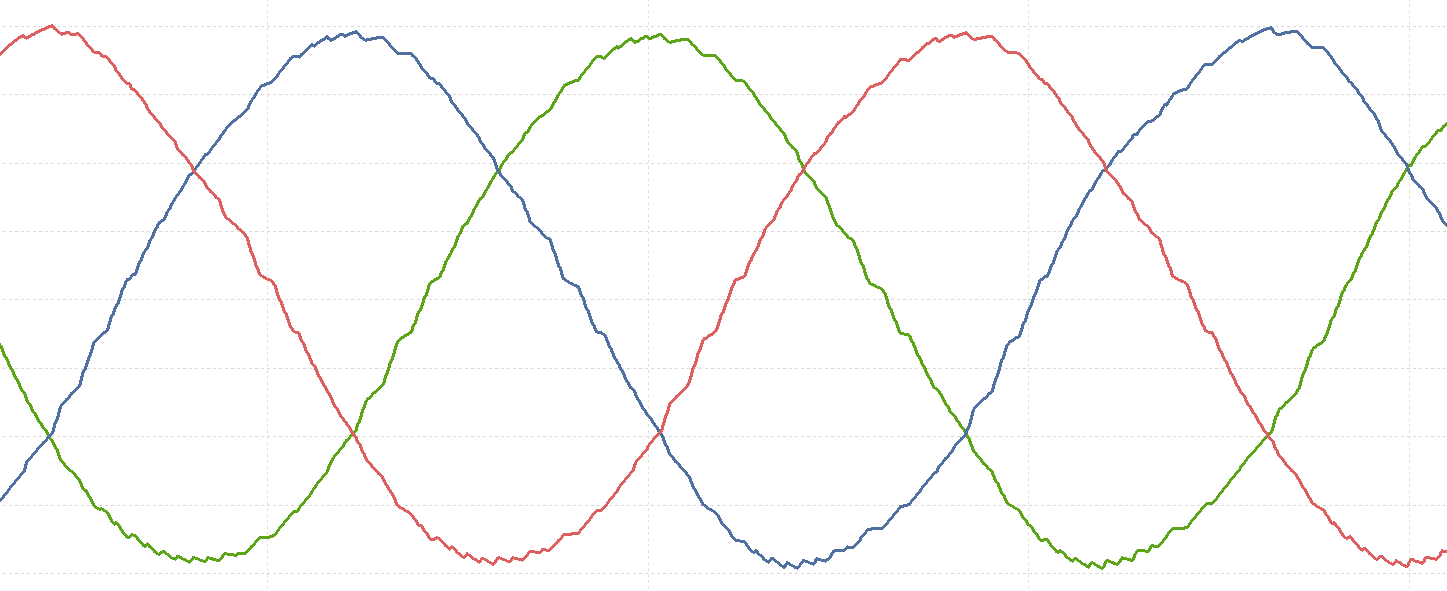

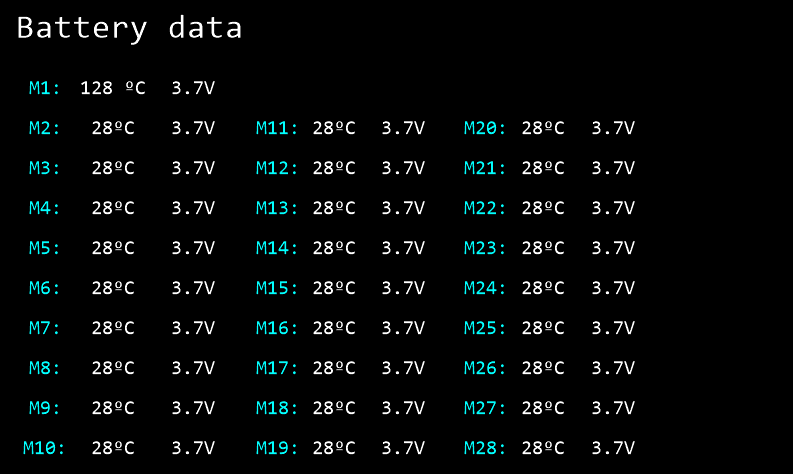

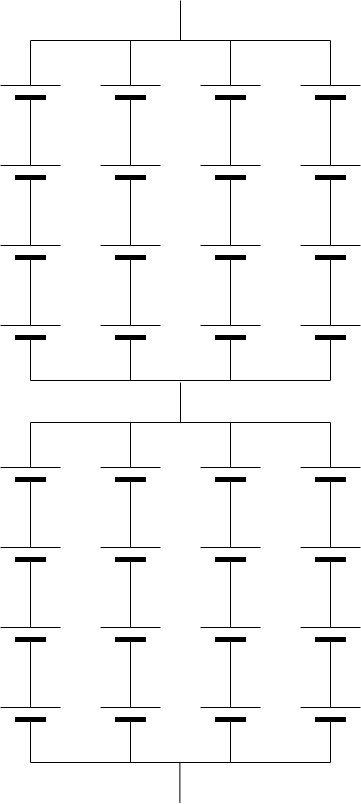

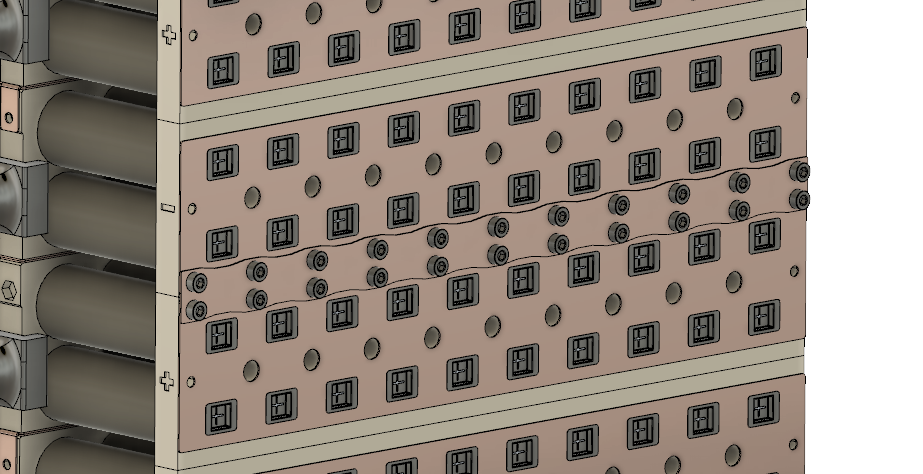

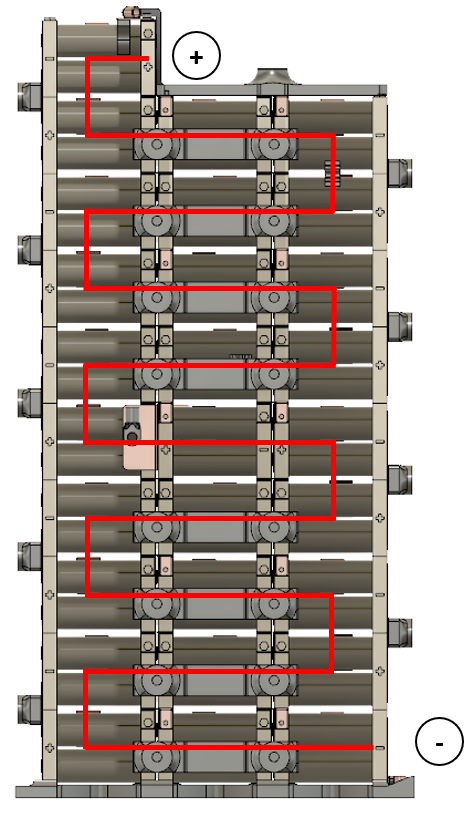

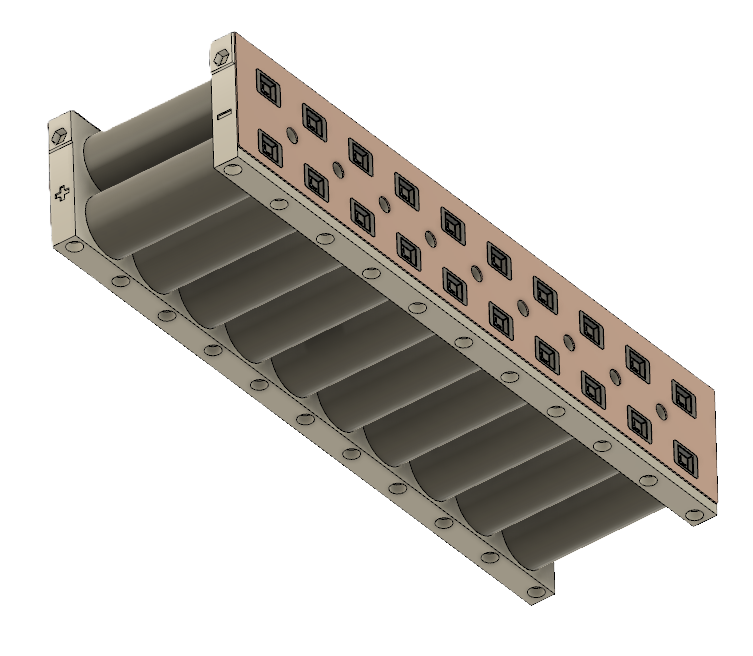

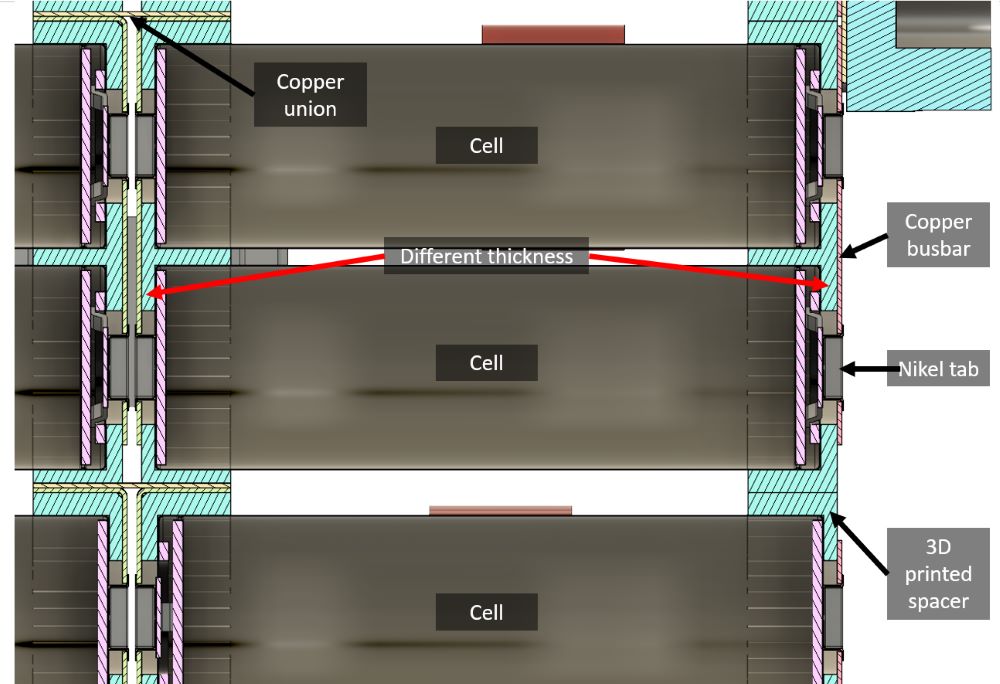

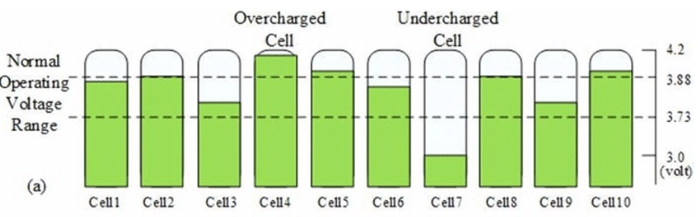

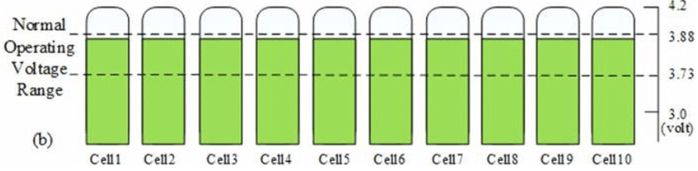

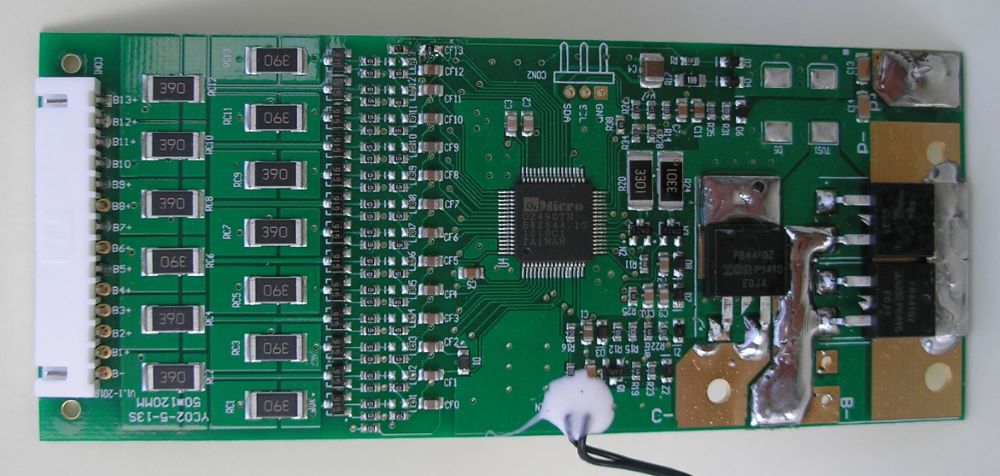

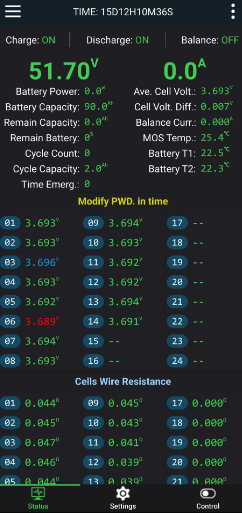

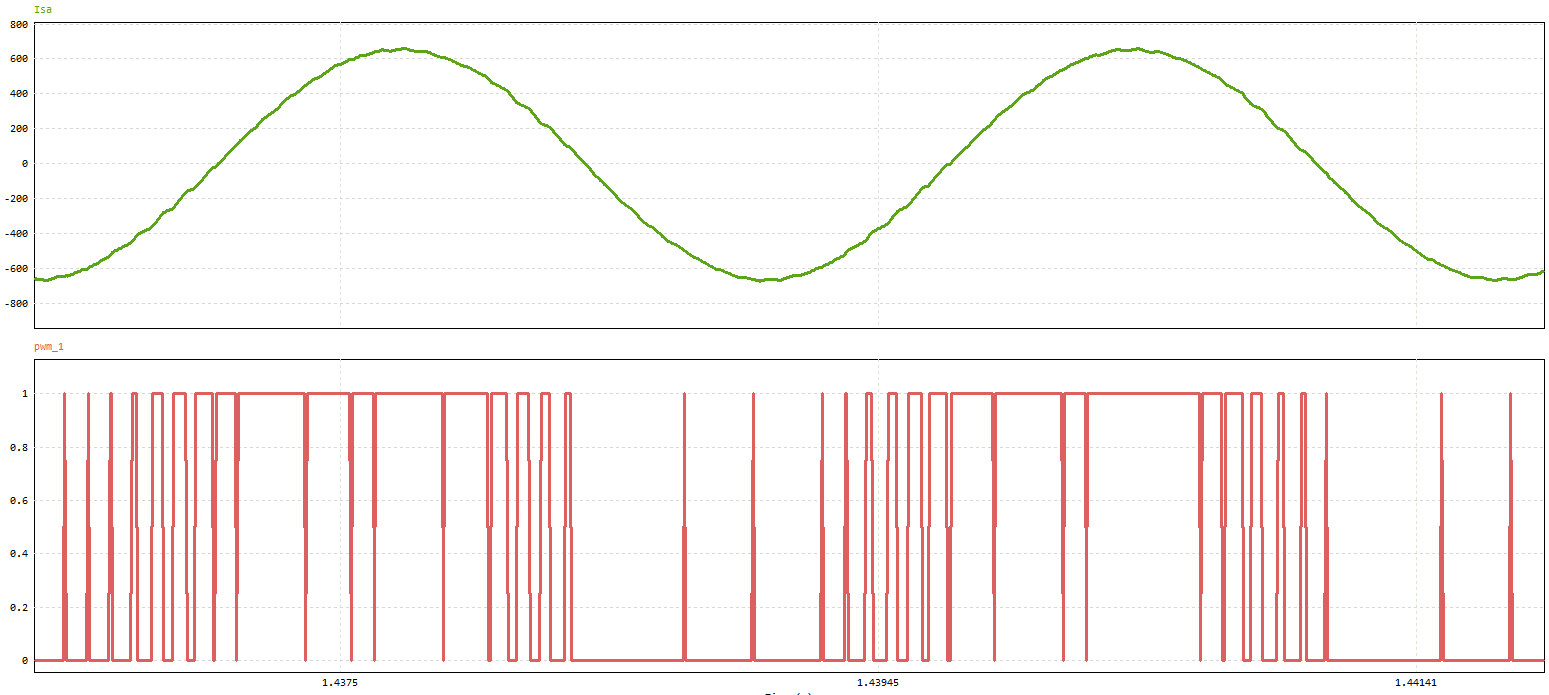

Let’s take a look at the HV scheme. We are using a 28s 20p battery configuration. This means that we have 28 series and 20 parallel cells. I will talk about this in more detail later, but to introduce the concept, with these lithium batteries, we need to control the voltage of all the series connections (monitoring the parallel connections is not necessary, as they automatically balance themselves).

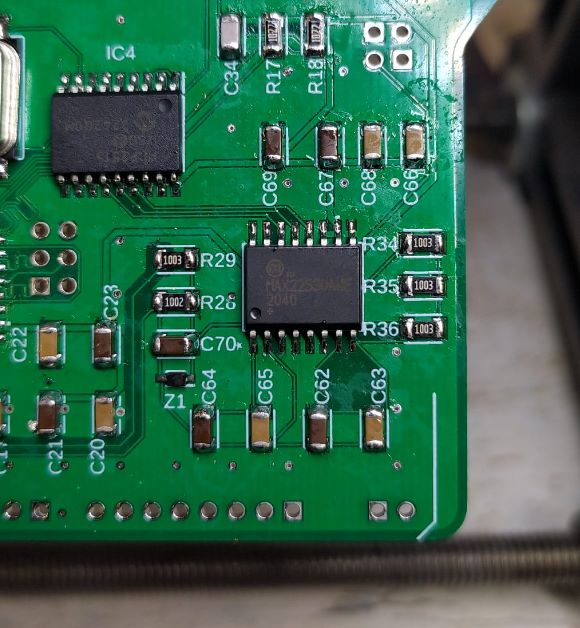

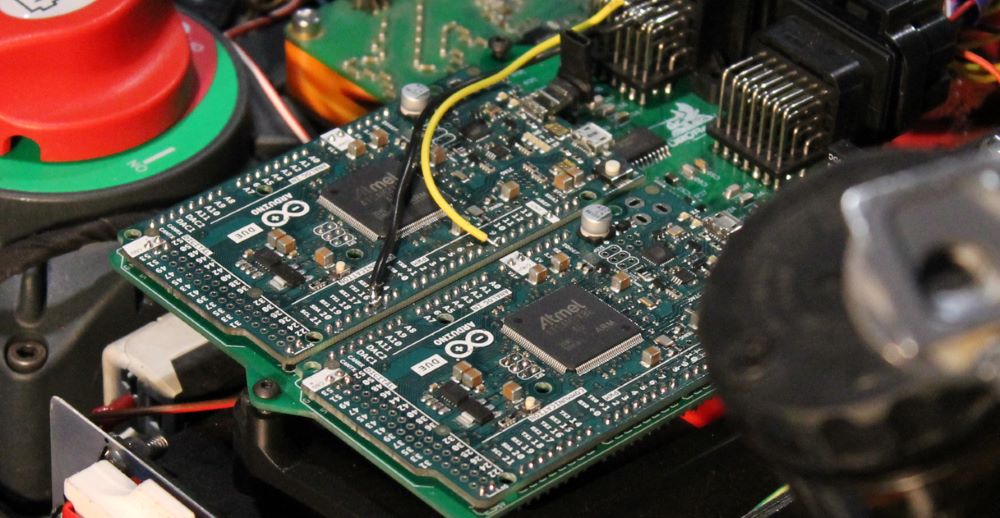

This is where the BMS (Battery Management System) comes in. Once we had the battery designed, we needed to charge it. The problem was that we had a sponsor who could provide us with some battery chargers, but these did not reach the 117V we needed. To solve this, we chose to charge the battery in two parts, as shown in the image. The chargers we planned to use are isolated between the DC and AC sides, allowing us to work with them in parallel even if the HV is connected to the inverter. The only common point between them is the data logger, as we use the BMS to read the cell voltage and store it. This was accomplished with two isolated CAN transceivers, preventing short circuits.

The BMS is used “only” for charging. I say “only” because current flows through them only during charging. For discharge, we are connected directly to the positive and negative poles of the battery, but we continue to use data from the BMS to monitor the voltage of each module. If something goes wrong (such as significant module imbalances or has low voltage), we cut the power to the battery. I will discuss this further in the section on the charging system.

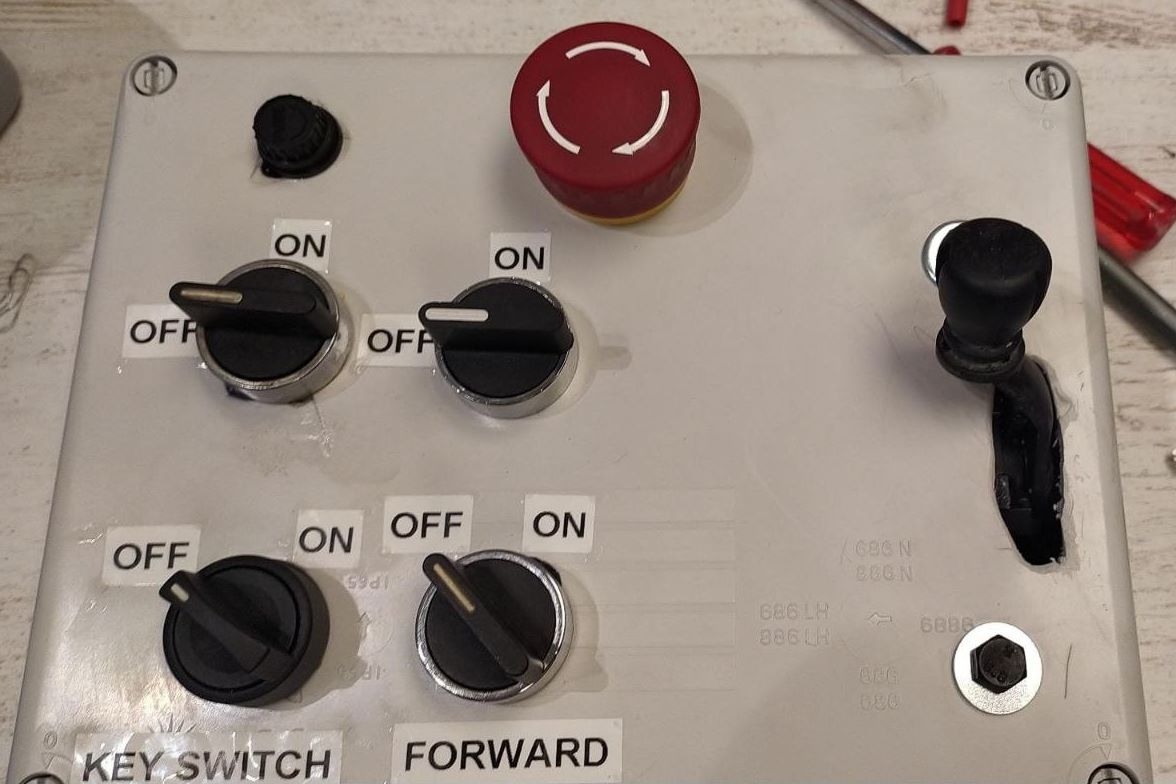

LV (Low Voltage) scheme

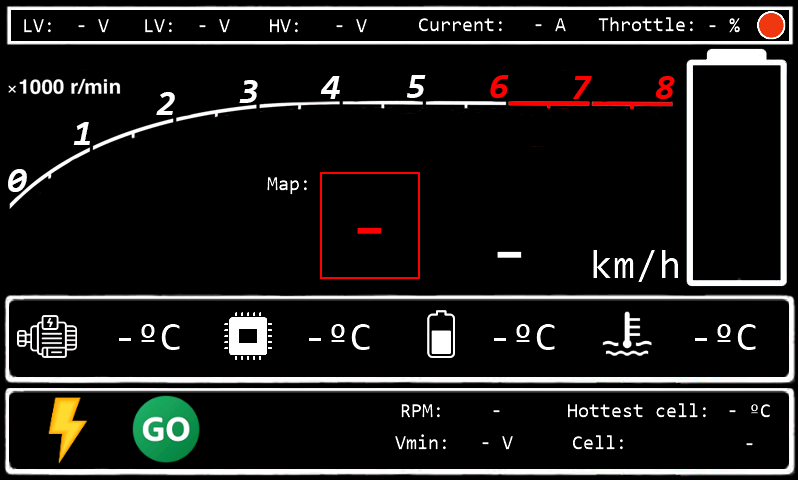

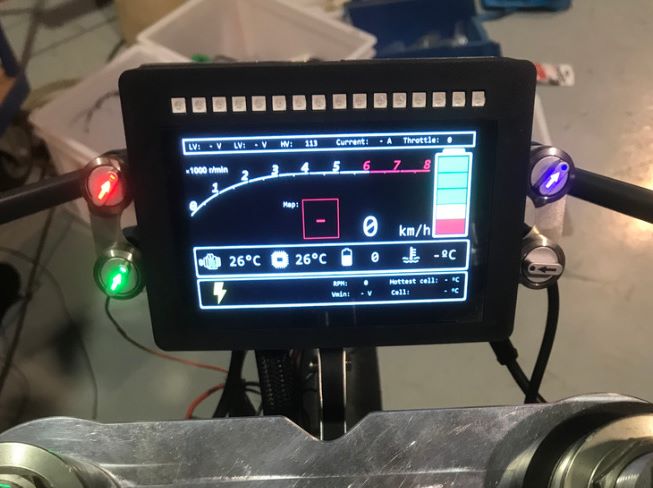

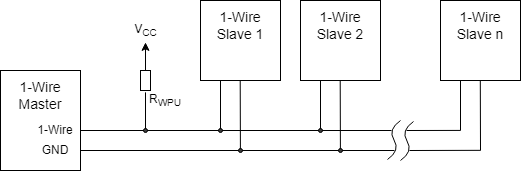

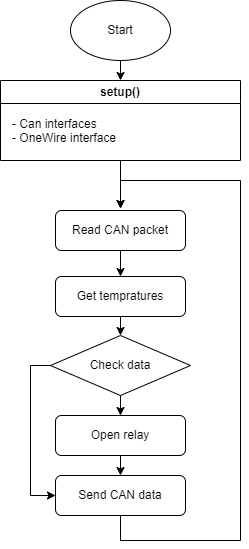

We have a simple electrical diagram with two batteries: one for the safety elements (IMD) and another for external components such as the data logger and the water pump. This setup provides a basic scheme for the operation of the prototype without mixing different functionalities.